Upstream Gas Turbine Inlet Fogging System

Up to 25% Power Boost – Even in Humid Climates

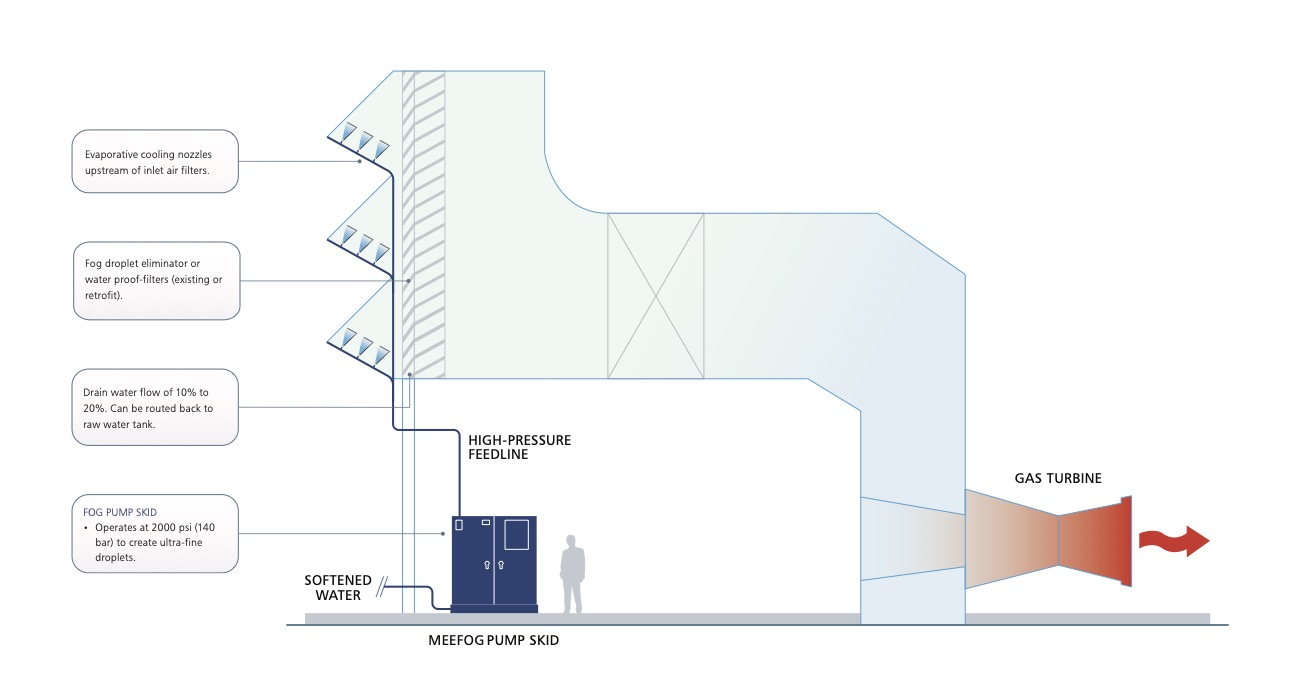

Upstream fogging is an inlet air cooling technique for gas turbines that cools the air stream before it enters the air filters. Upstream fogging is especially ideal when filter house design constraints or long-term service agreements restrict installation of the fog nozzles inside the air intake duct.

Upstream fogging also pre-filters the air. Fog spray that does not evaporate is collected on a droplet eliminator or on water resistant pre-filters. The drain water flow carries away dust that would otherwise accumulate on the pre-filters. Drain water can be treated and reused. By installing MeeFog nozzles ahead of the inlet filters, you gain a flexible, rapid power boost.

With over 1,000 installations over the past 30 years, Mee Industries is the trusted leader in inlet air fogging – delivering unmatched reliability, performance, and long-term value.

MeeFog Upstream Systems Include:

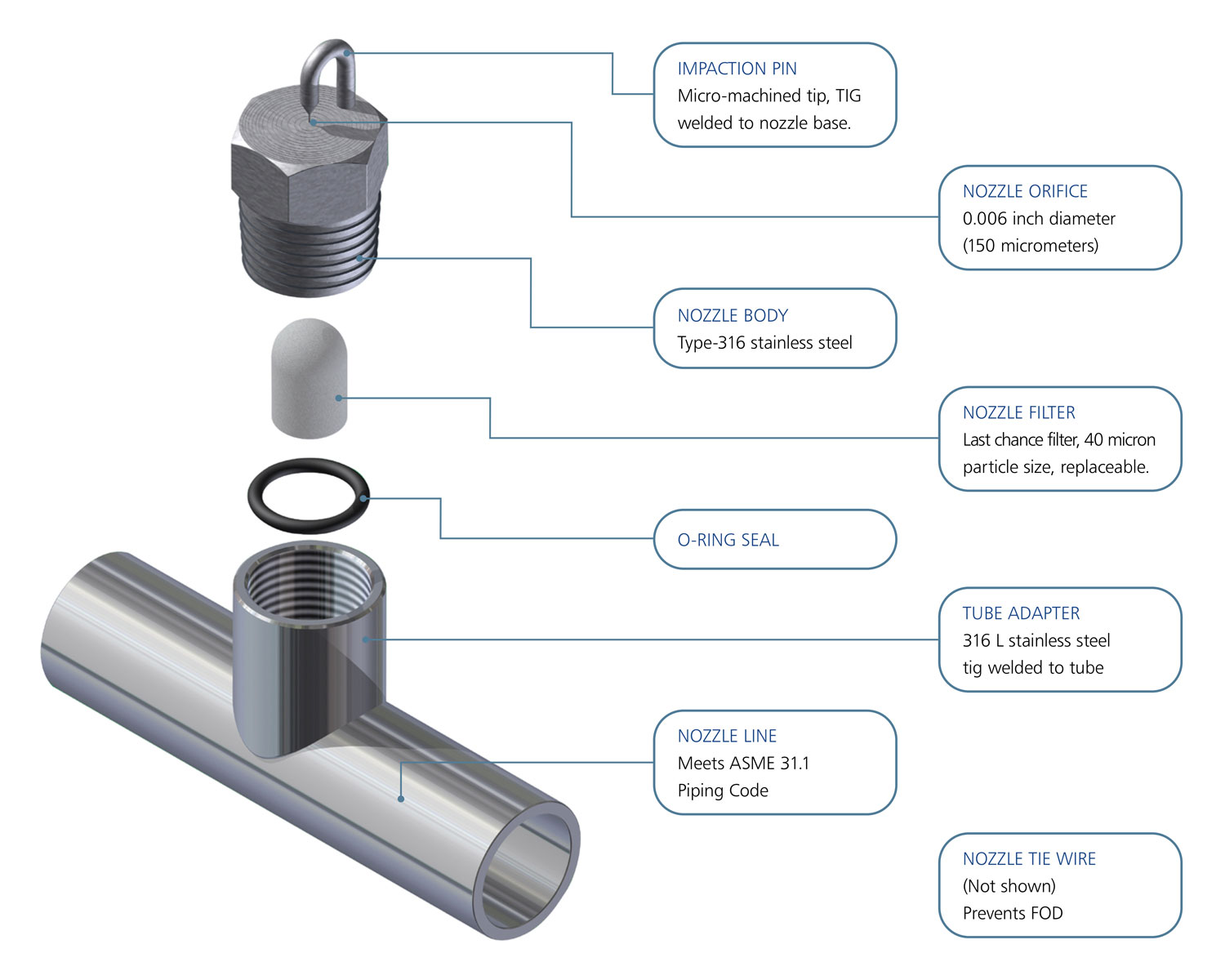

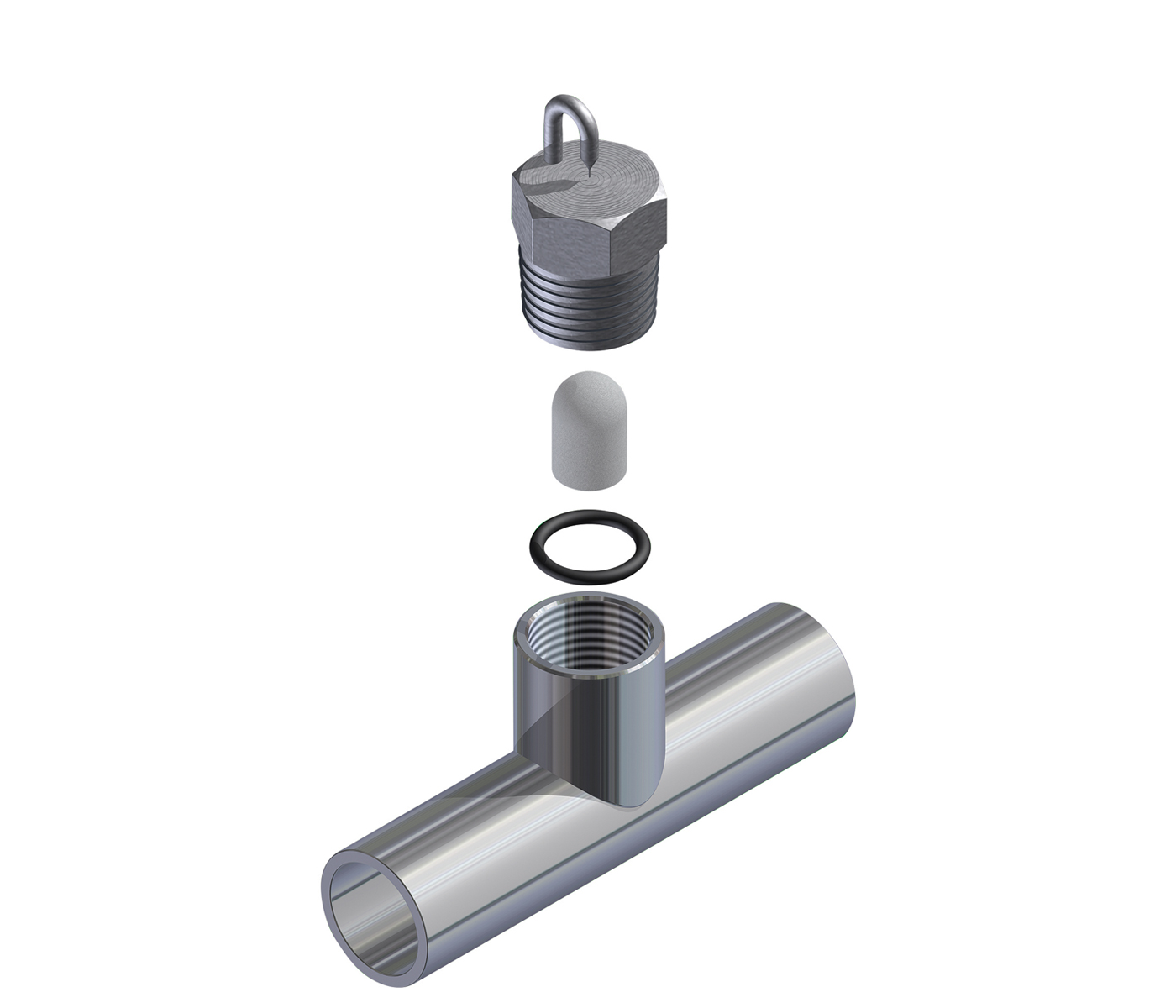

- High-efficiency fog nozzles with stainless steel construction

- Droplet eliminators or coalescer filters for effective moisture control

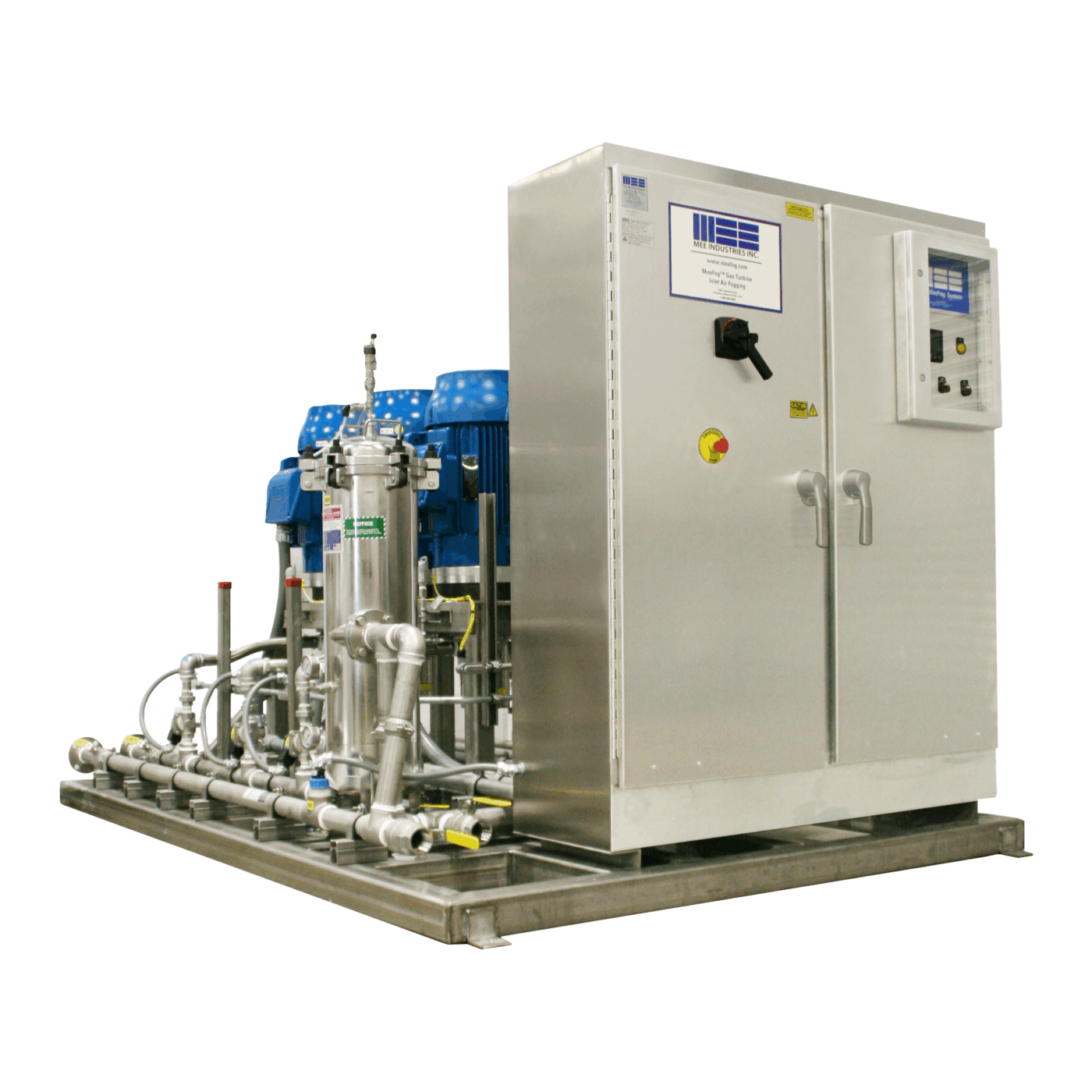

- Pre-engineered pump skids with PLC controls

- Integration with your DCS

We’ll gladly evaluate your specific requirements and deliver a detailed performance forecast for your site including:

- Installed system cost.

- Guaranteed power gains.

- Predicted water usage.

- ROI.

System Overview

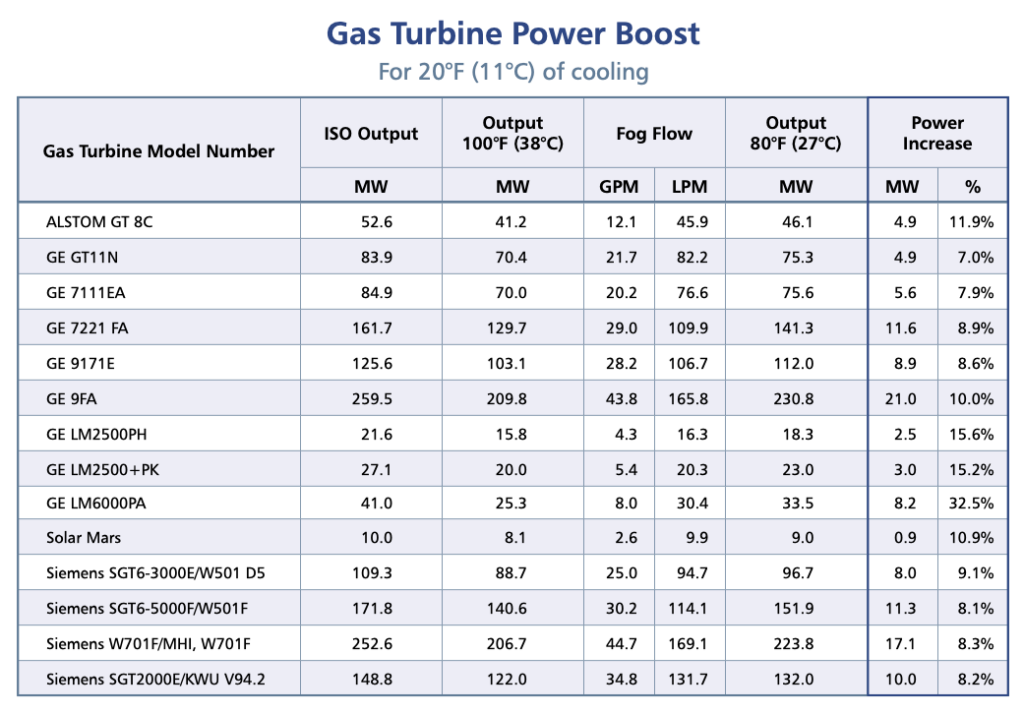

Power Boost

MeeFog System Benefits

- Fog cooling increases output by 20% or more.

- Overspray fogging provides additional boost.

- Reduced NOx emissions up to 30%.

- Improved fuel economy.

- Reduced CO2 per kW of power.

- Robust equipment & proven technology.

- Guaranteed results!

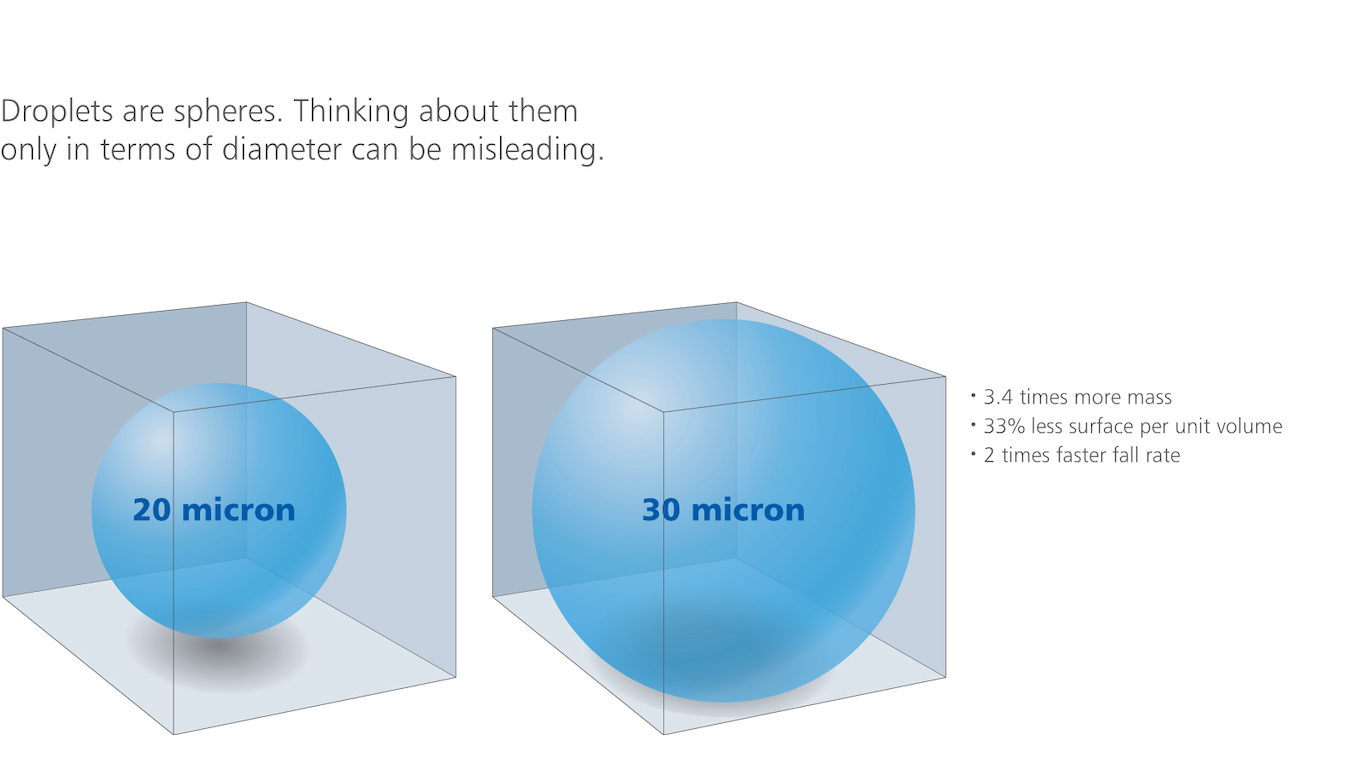

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed power recovery report for your existing gas turbines including:

- Installed MeeFog system cost.

- Predicted MW-hr gain per year.

- Fuel savings.

Featured Case Study

Upstream Fogging Is Making a Comeback for Gas Turbines

Placing fogging systems upstream of filters helps plant operators improve air filter life, reduce maintenance costs, and boost turbine performance. MeeFog upstream systems deliver powerful cooling while capturing airborne dust, protecting critical components, and extending equipment life. Partnering with Mee Industries can help increase power output, lower lifecycle costs, and ensure that operations remain efficient and reliable for years to come.