Laboratory Humidification Systems

Precise Industrial Humidifiers – Built to Last

Humidification systems stabilize the environment by reducing fluctuations in temperature and humidity. Testing labs require close environmental control to maintain integrity of results. Labs often require 100% outside air and this large load of humidification is a perfect place to apply an energy-efficient MeeFog system.

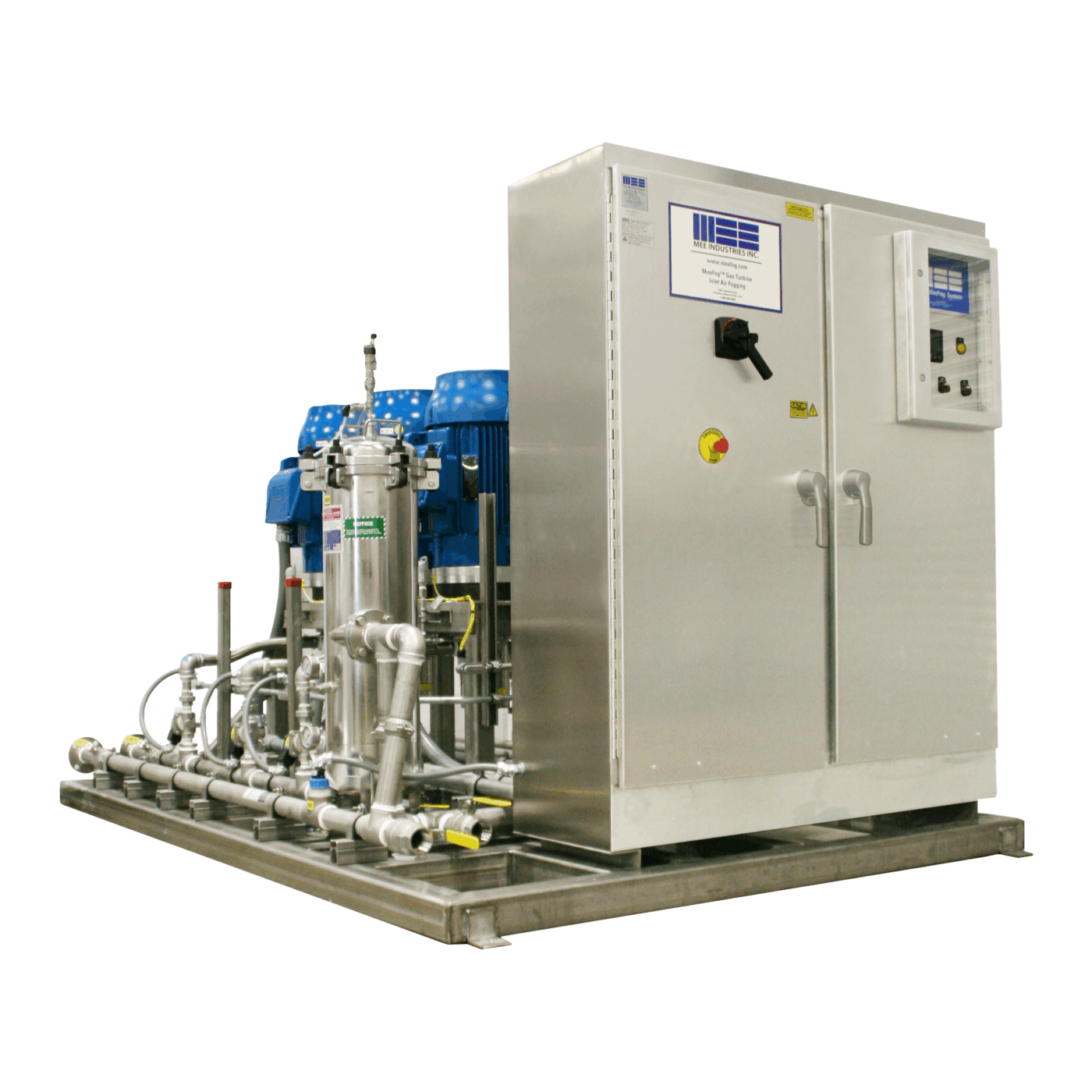

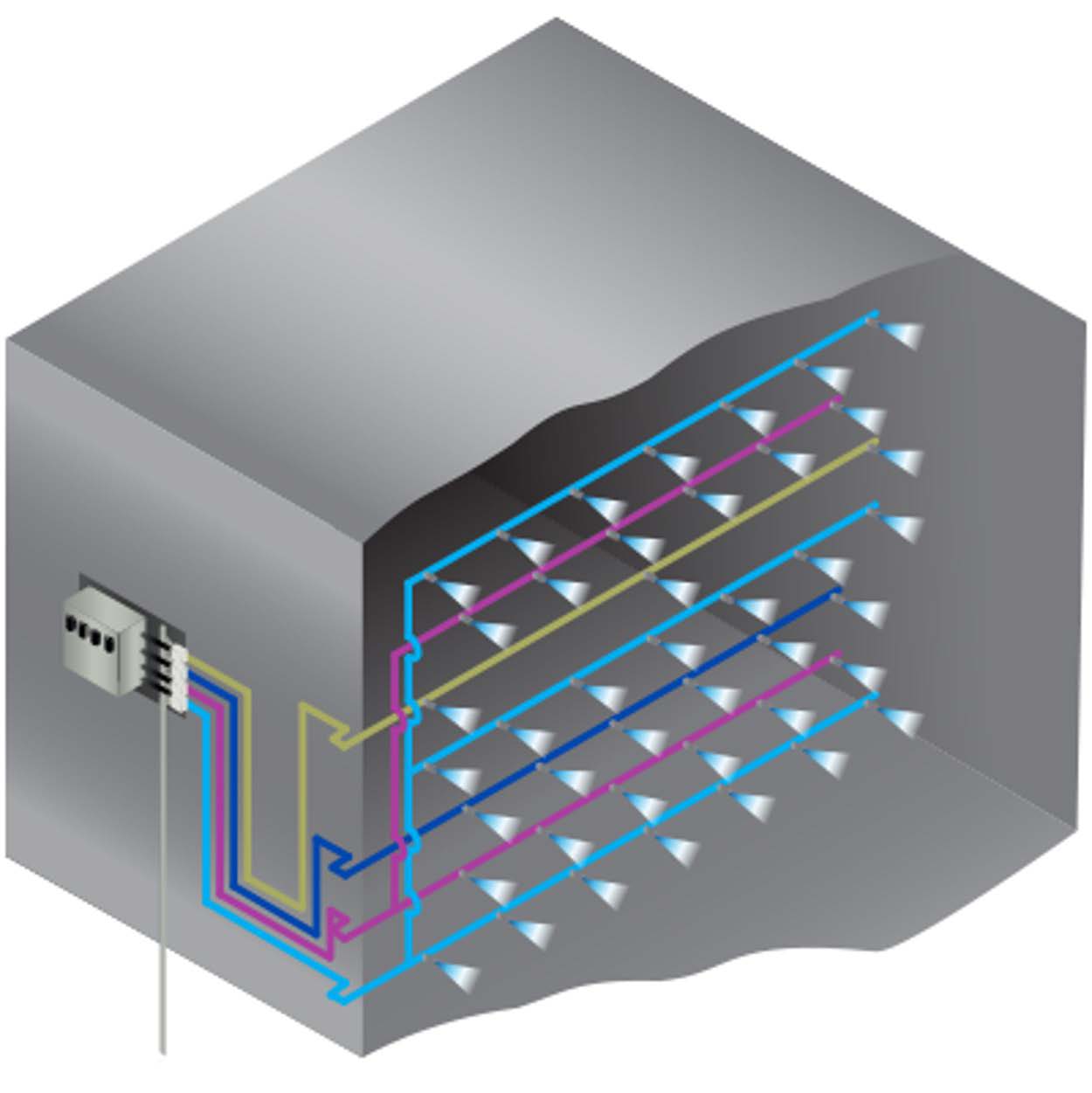

MeeFog systems consist of a pump rack with VFD, pressure transducers, and a single point power connection. The unit works as a central humidification system – distributed piping supplies multiple air handlers in a building to separately control the amount of humidity introduced into the air at each room or location.

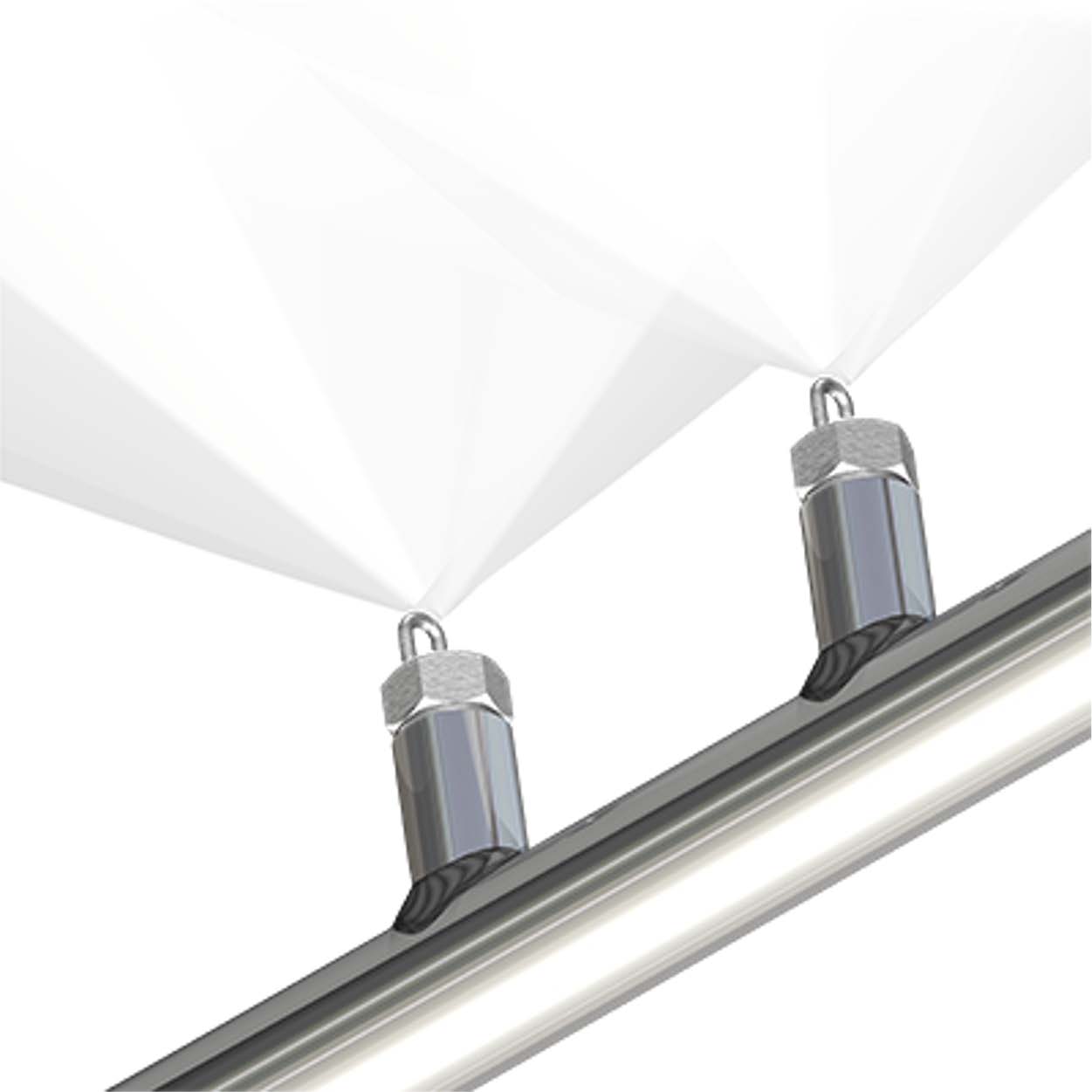

High-pressure fog nozzles atomize water into billions of ultra-fine droplets. The small droplet size from a MeeFog nozzle results in higher evaporation and absorption rates. A MeeFog system will typically pay for itself within one year through savings on operating and maintenance costs.

Benefits:

- Reduced energy consumption.

- Lower maintenance costs.

To find out more about how the system can work for you, contact a MeeFog sales engineer.

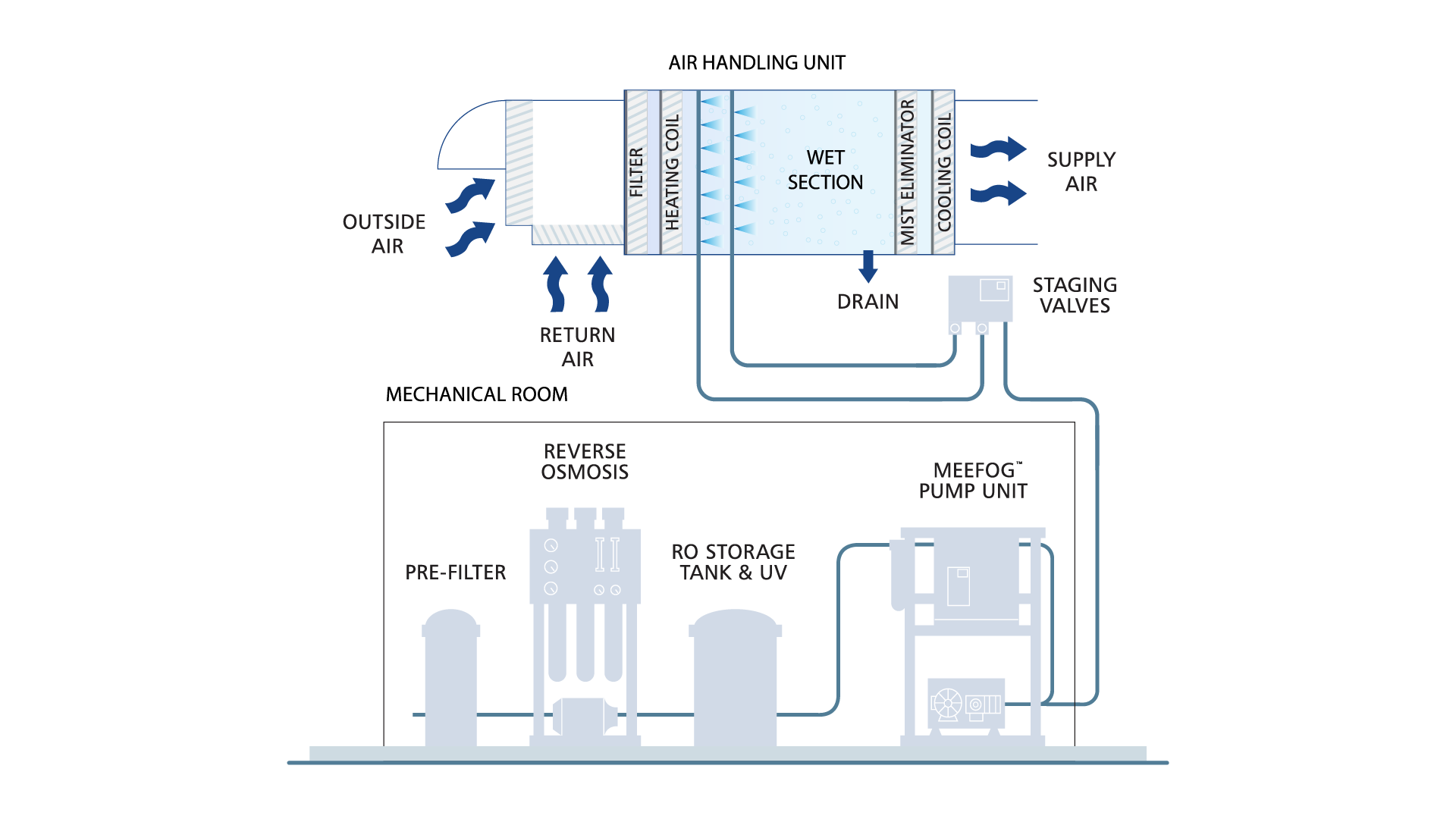

MeeFog HVAC Installation Diagram

Click the different areas of the diagram below to learn more information about our system.

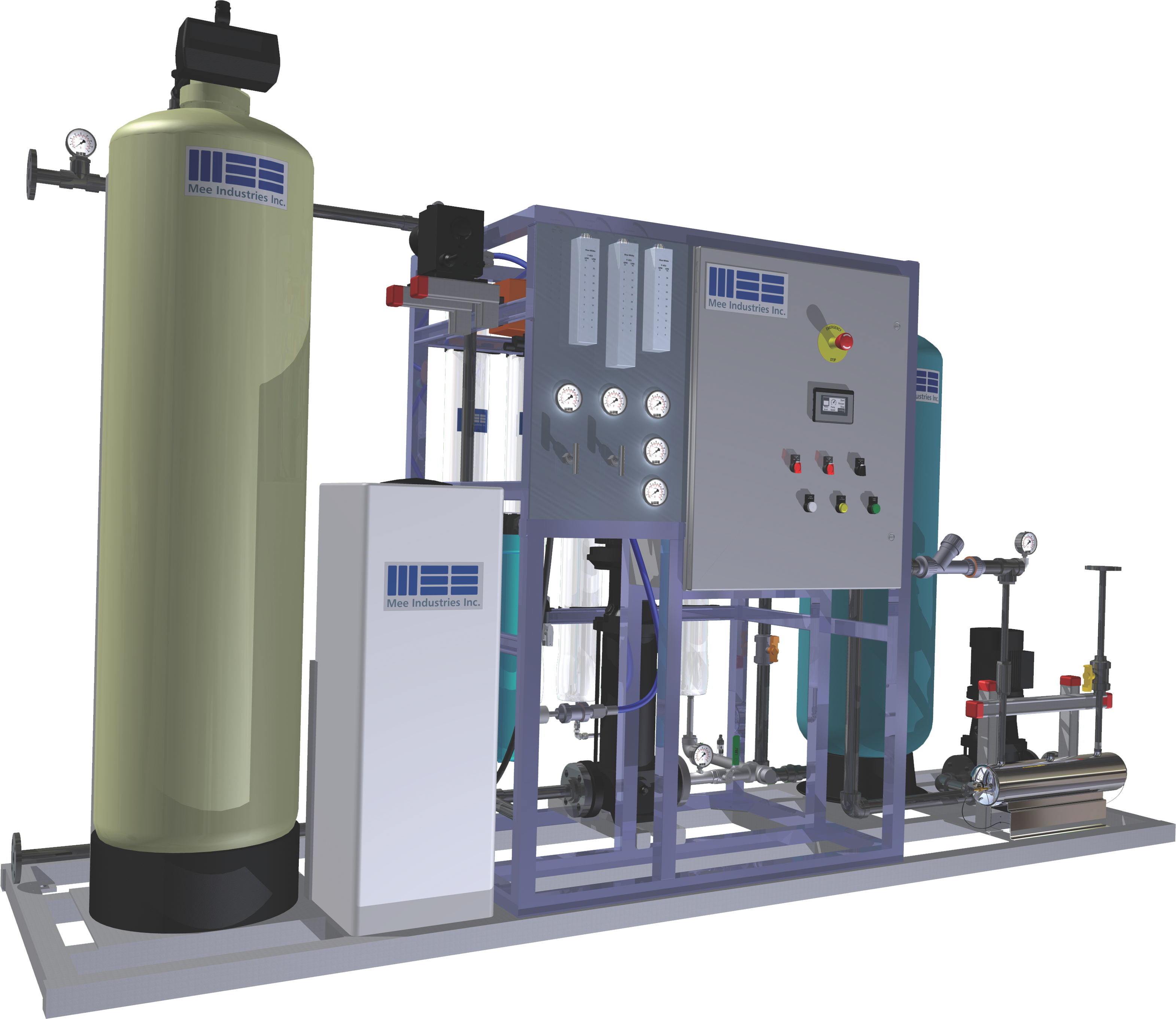

Reverse Osmosis Water Purification

Reverse Osmosis Water Purification

City water is treated using the Reverse Osmosis water treatment rack. This purifies the water, removing minerals, particulate, and microorganisms. Systems include automated membrane flushing, pre-treatment filtration, and UV Re-Circulation.

MeeFog Pump

MeeFog Pump

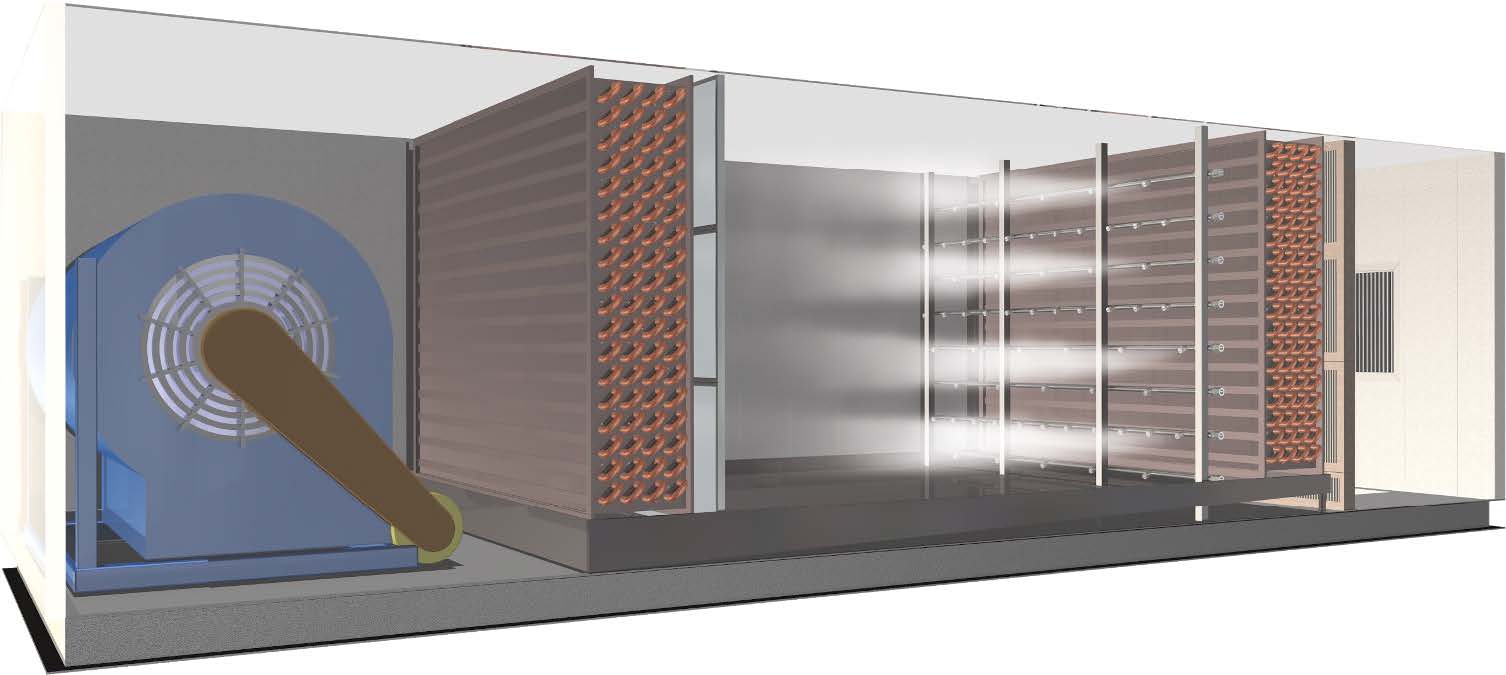

The high-pressure pump maintains 1000 psi water pressure in order to atomize the water into tiny droplets that can evaporate into the air stream. The pump rack has a VFD with panel-mounted controller that maintains pressure when staging valves open and close.

Staging Valves

Staging Valves

The valve panel allows precise control over how much humidification is injected into the air stream based on a signal from the BMS. It is possible to control the humidification level in the space to plus or minus 1% RH.

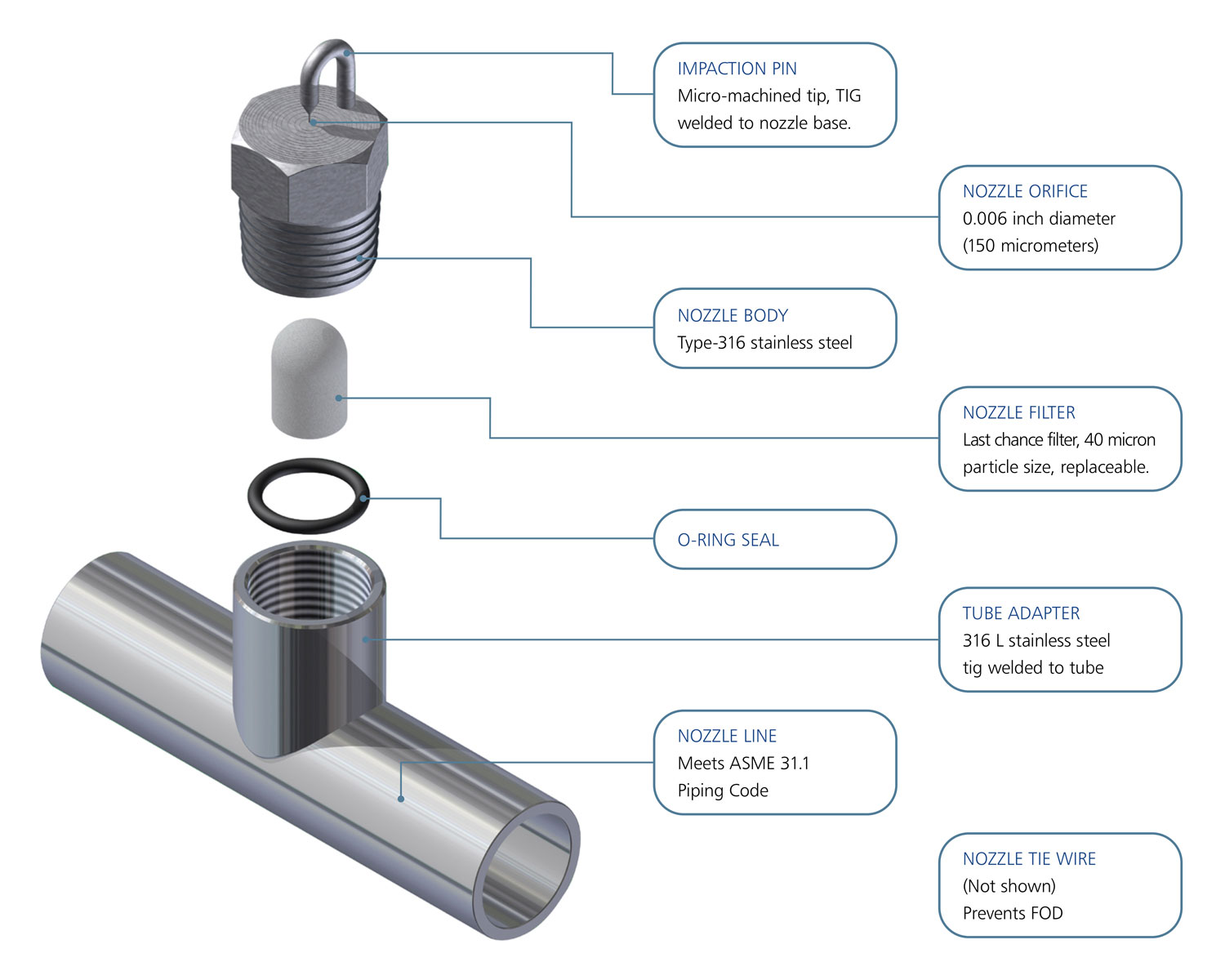

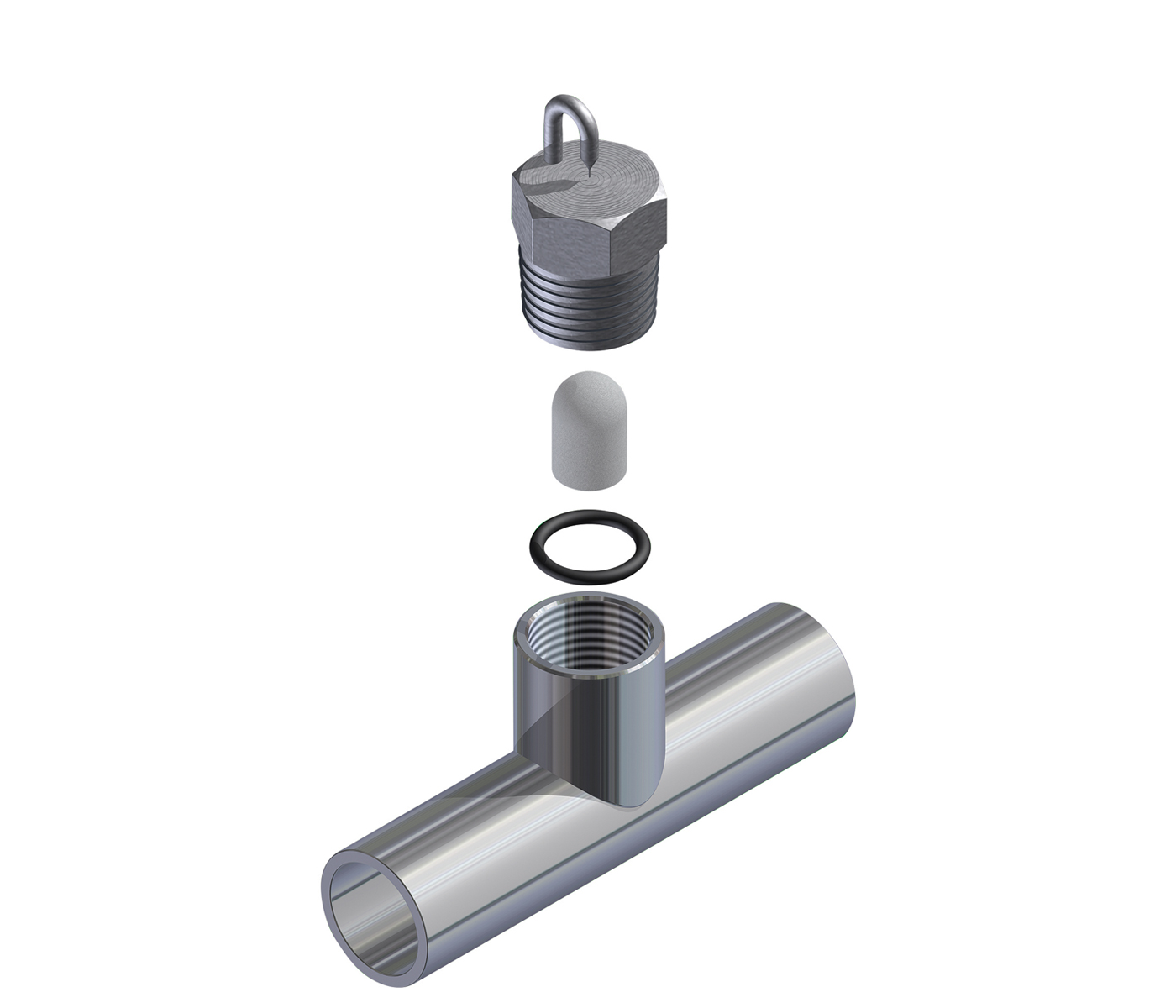

Nozzle Manifolds

Nozzle Manifolds

Fog nozzles are mounted on stainless steel tubing inside the air handler. These nozzles produce droplets in the 10-micron range. These precision nozzles are manufactured and tested in Mee Industries' own facility.

Mist Eliminator

Mist Eliminator

The mist eliminator removes water droplets larger than 5 microns. The filter pads can come off their stainless steel frames and can be washed or replaced easily.

System Overview

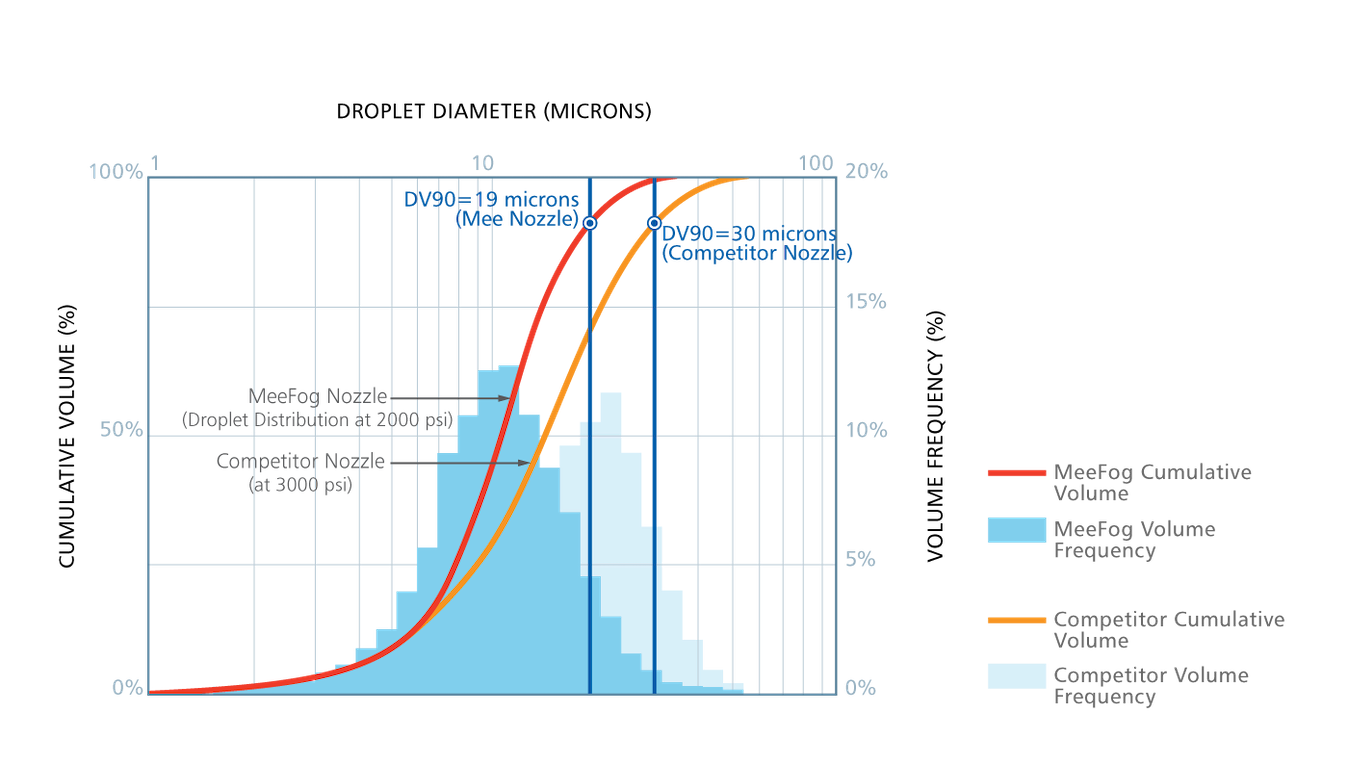

Nozzle Comparison

At an operating pressure of 2000 psi, the resulting average droplet size is roughly one tenth the diameter of a single strand of human hair.

MeeFog System Benefits

- Minimizes the risk of airborne infections.

- Decreases the occurrence of respiratory issues in newborns.

- Low energy consumption.

- Precise humidity level control.

- Elevates patient and staff overall comfort and virus protection.

- Lowers employee absence rate.

- Reduces premature drying and formation of scabs from coagulated blood.

- Prevention of electrostatic damage to medical equipment.

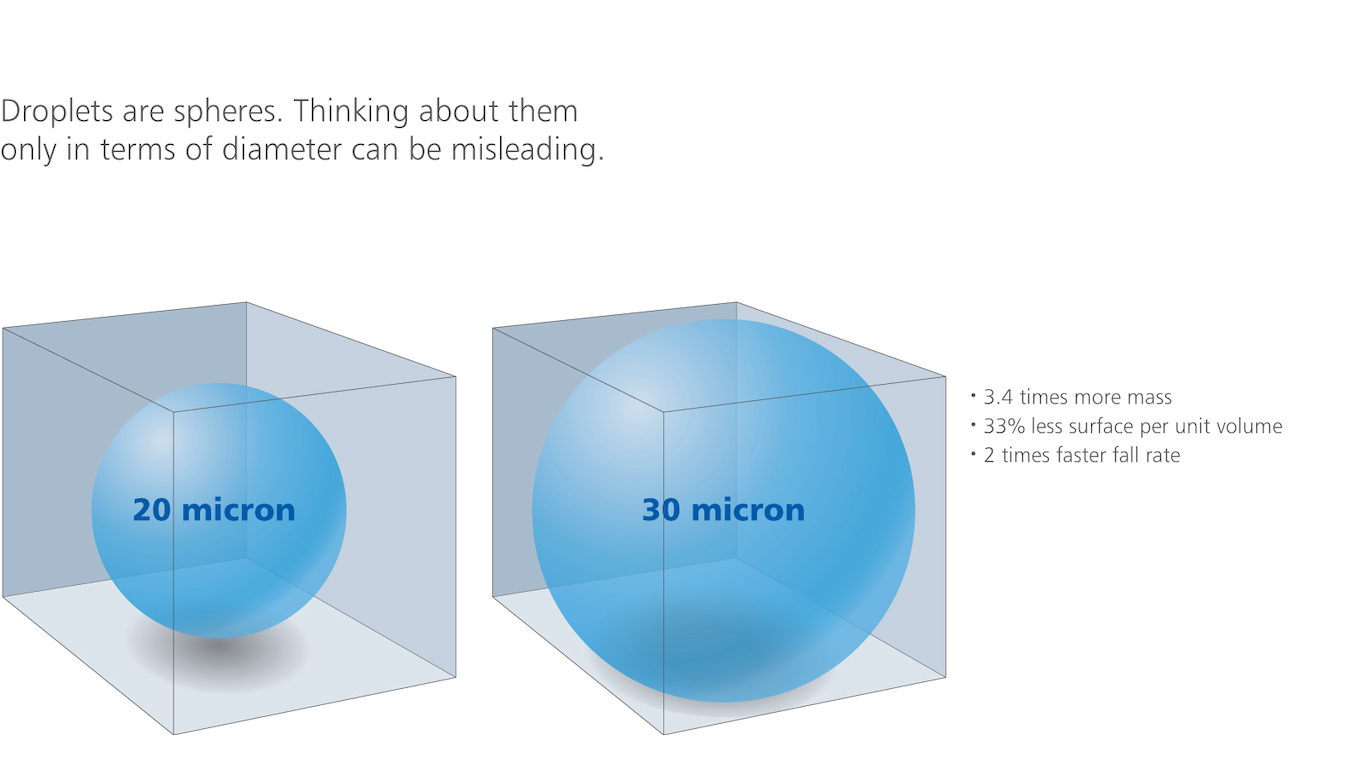

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed payback analysis report for your Hospital or Medical Center including:

- Installed MeeFog system cost.

- Predicted process gains per year.

Laboratories FAQ

Labs often operate with 100% outside air, creating a large humidification demand to ensure accurate results and safe handling of sensitive materials. Without proper humidity control, labs face issues such as electrostatic discharge (ESD), compromised experiments, and poor indoor air quality. MeeFog systems deliver precise, energy-efficient humidification while lowering HVAC energy consumption, making them an ideal fit for laboratory environments. Proper humidification, often within the 40–60% range, is critical for maintaining research integrity and lab safety.

Medical device facilities and other ESD-sensitive environments require stable humidity to prevent static discharge and protect sensitive equipment. MeeFog uses high-pressure fogging to maintain optimal humidity levels, ensuring regulatory compliance, production consistency, and safe operation of sensitive electronics in labs and manufacturing facilities.

The 170,000 sq. ft. NCAR Supercomputing Center in Wyoming uses MeeFog to protect its IBM Yellowstone supercomputer from ESD. The dry Wyoming climate is ideal for free cooling, but it creates a risk of dangerously low humidity. By installing MeeFog, NCAR delivers fog directly into the AHUs and supply air, maintaining safe humidity levels while saving energy. The system operates through two FM-200-B271P ceramic plunger pumps at 1000 psi, integrated with the Johnson Metasys controls for precise automation.

MeeFog avoids the high energy costs of steam by using a small horsepower pump instead of boilers. The system consumes up to 90% less energy than steam humidifiers, while also providing adiabatic cooling that reduces chiller use. For labs running 24/7 with high ventilation loads, the operational savings are substantial, often delivering ROI in 1–3 years.

Yes, MeeFog systems can be fully integrated with Johnson Controls, Siemens, Honeywell, and other BAS platforms. At NCAR, the MeeFog system ties into the Johnson Metasys controls to regulate both temperature and humidity in real-time, ensuring reliability under fluctuating outdoor air conditions.

By reducing reliance on steam and minimizing chiller loads, MeeFog systems support sustainable lab design and contribute to LEED certifications. NCAR selected MeeFog as part of its “right-sized” construction strategy, providing reliable humidification for 20–30 years while cutting energy and operational costs.

Featured Case Study

Army Research Laboratory Uses CHP and MeeFog Humidification to Cut Energy and O&M Costs

The Challenge:

The Army Research Laboratory in Adelphi, Maryland had been using a boiler to provide hot water as well as steam humidification to two clean rooms. It recently installed a combined heat and power system in its central utility plant, but the hot water generated was not hot enough to provide needed humidification.

The Solution:

A Meefog system was installed to provide humidification to both clean rooms, at a much lower cost and with less maintenance than the boiler.

The Army Research Laboratory in Adelphi, Maryland had been using a boiler to provide hot water as well as steam humidification to two clean rooms. A MeeFog system was installed to provide humidification to both clean rooms, at a much lower cost and with less maintenance than the boiler.