Gas Turbine Inlet Air Cooling Systems for Power Optimization

Boost Power with the Cost-Effective MeeFog System

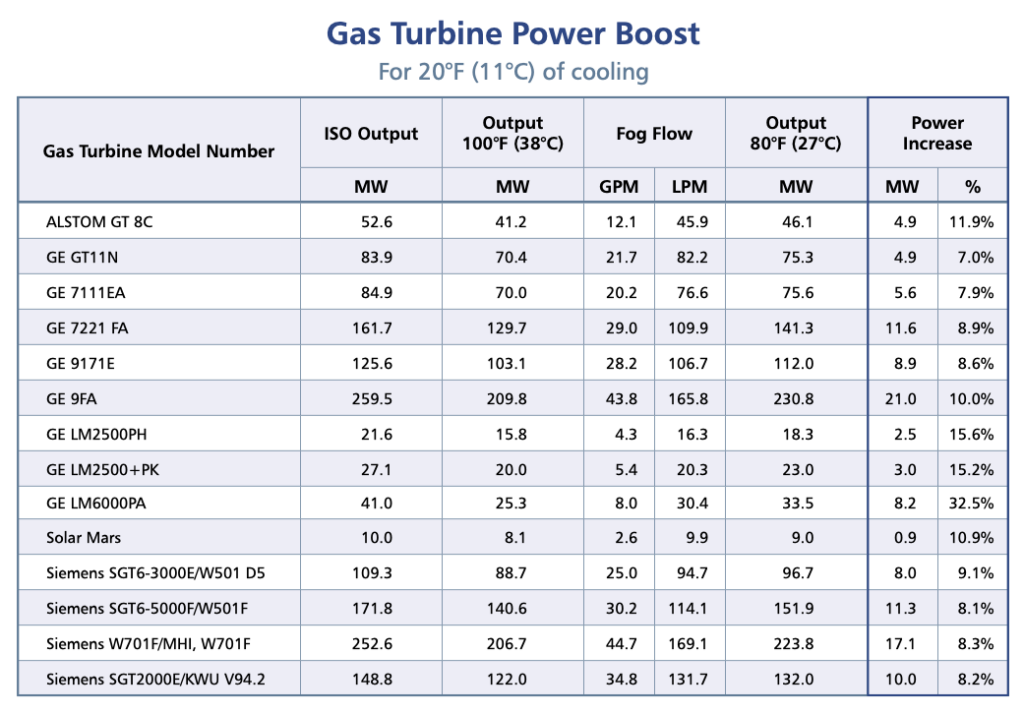

Cooling the inlet air of a gas turbine increases power output and improves fuel efficiency. The performance boost is greater in dry climates but remains economically significant even in humid conditions. A turbine’s output depends on the air mass flowing through its compressor. Because the volume of air per revolution remains constant, reducing the temperature increases air density and power output. Cooler, denser air also reduces compressor work, lowering parasitic load and saving energy.

Using evaporative cooling for gas turbine air inlet is effective in all climates, from areas with cool summers to the high heat and humidity of the Tropics. The MeeFog gas turbine inlet air cooling system is both effective and economical. With over 1,000 installations across 30 years, Mee Industries continues to lead in this advanced cooling technology.

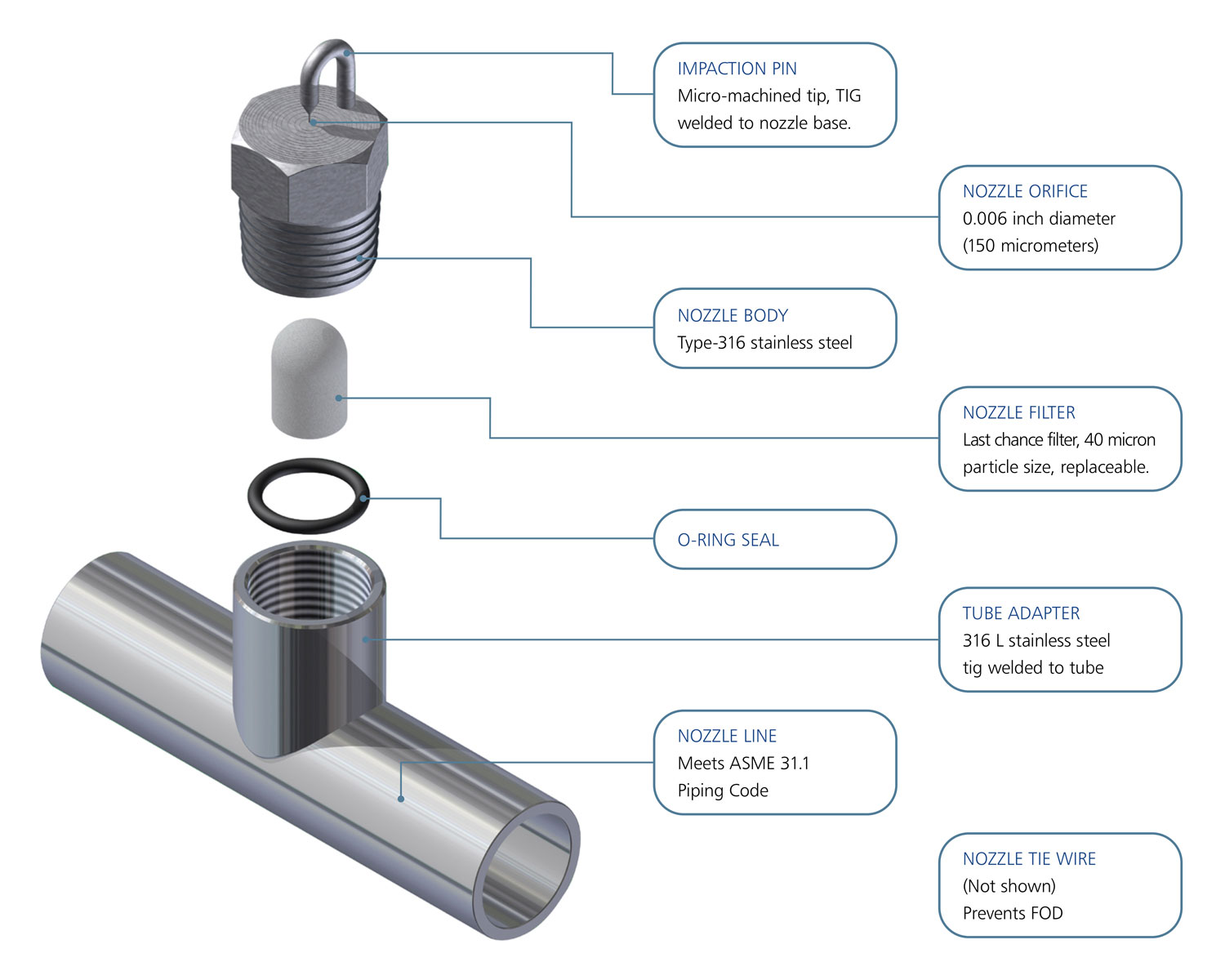

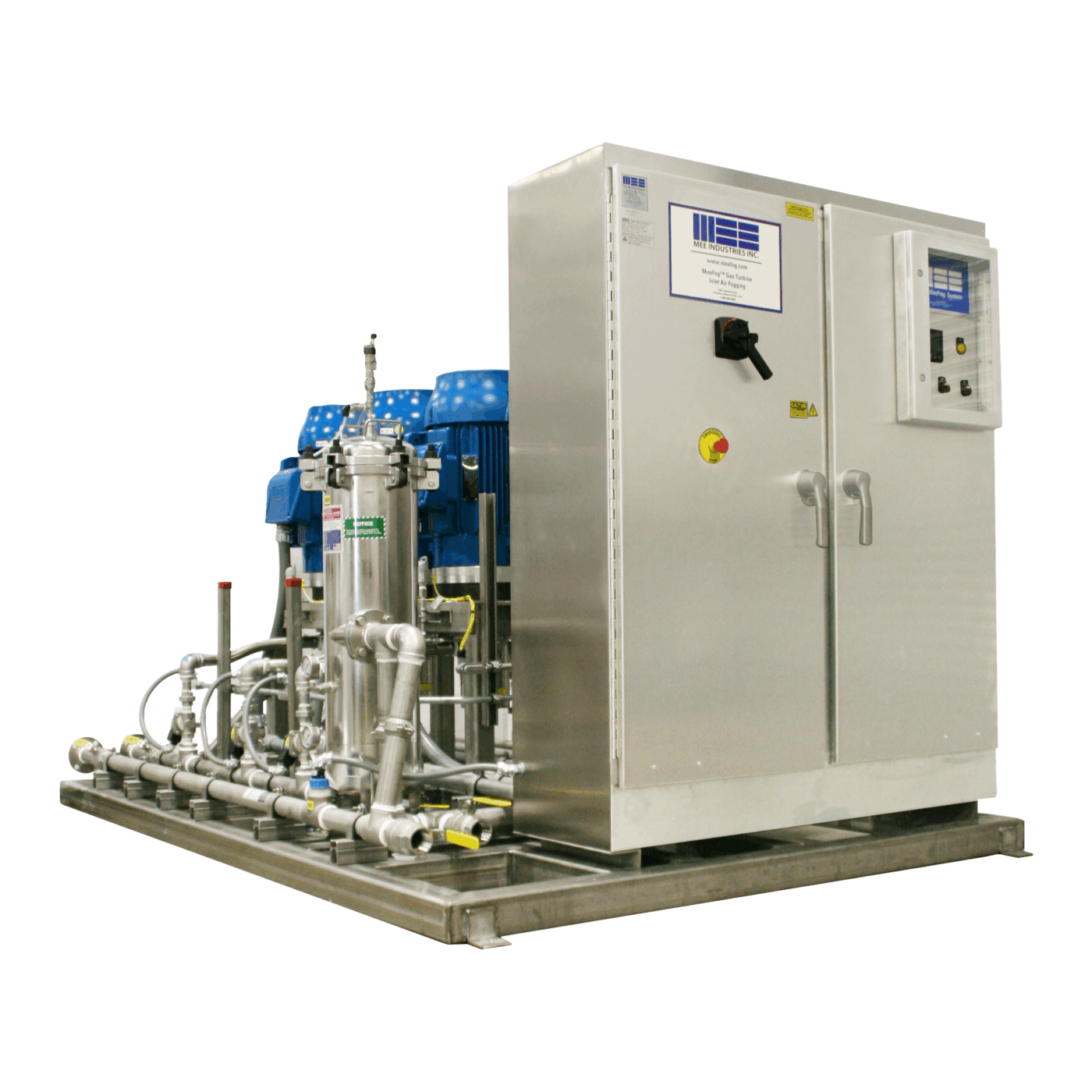

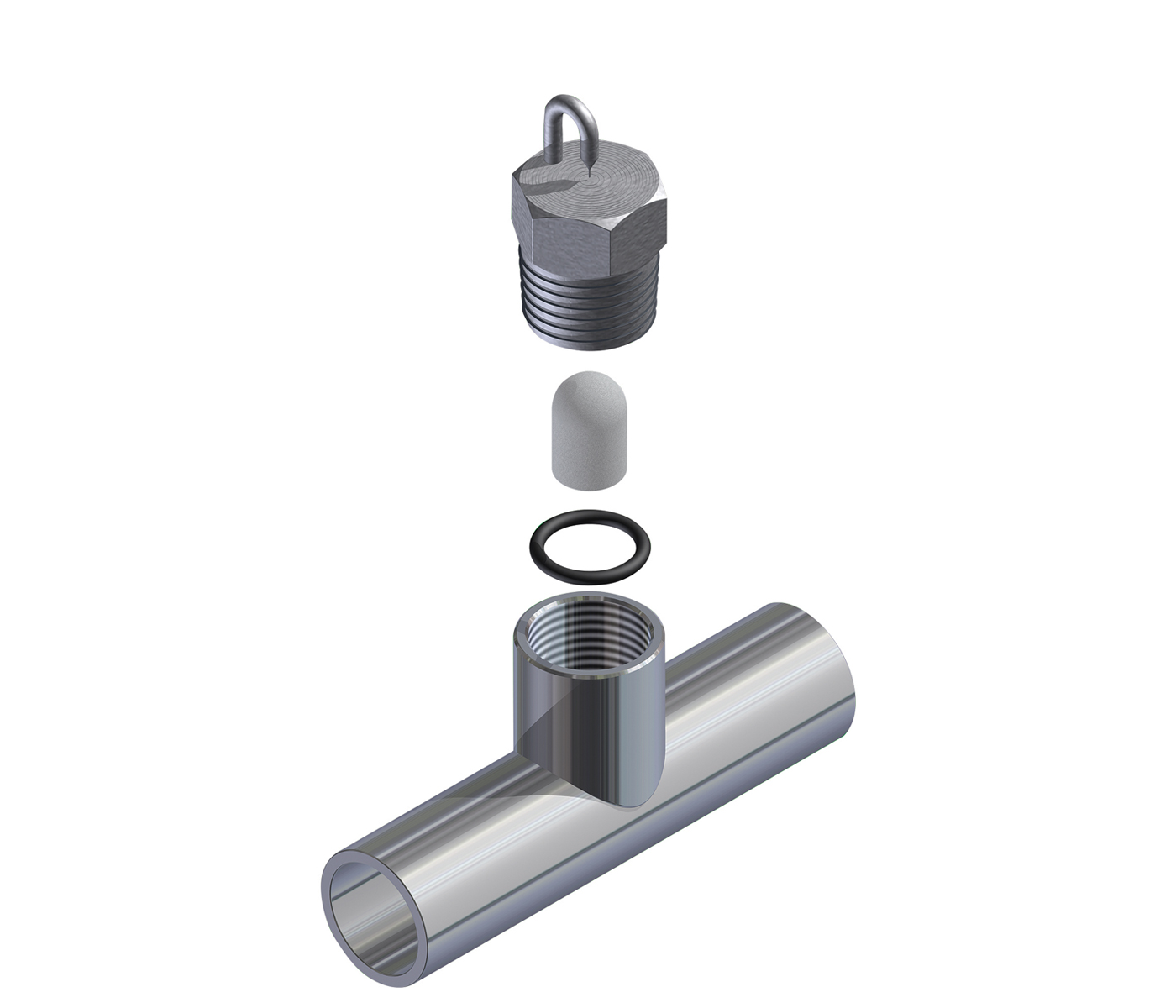

The fogging process is simple. Demineralized water is pressurized to 2,000 psi (138 bar) using the MeeFog pump skid. This water flows through MeeFog nozzles that inject a fine water mist directly into the gas turbine air inlet for cooling the airflow.

We gladly provide a detailed power recovery report for your existing gas turbines, including:

- Installed system cost.

- Guaranteed power gain.

- Predicted MW-hr gain per year.

- Improve the heat rate up to 5%.

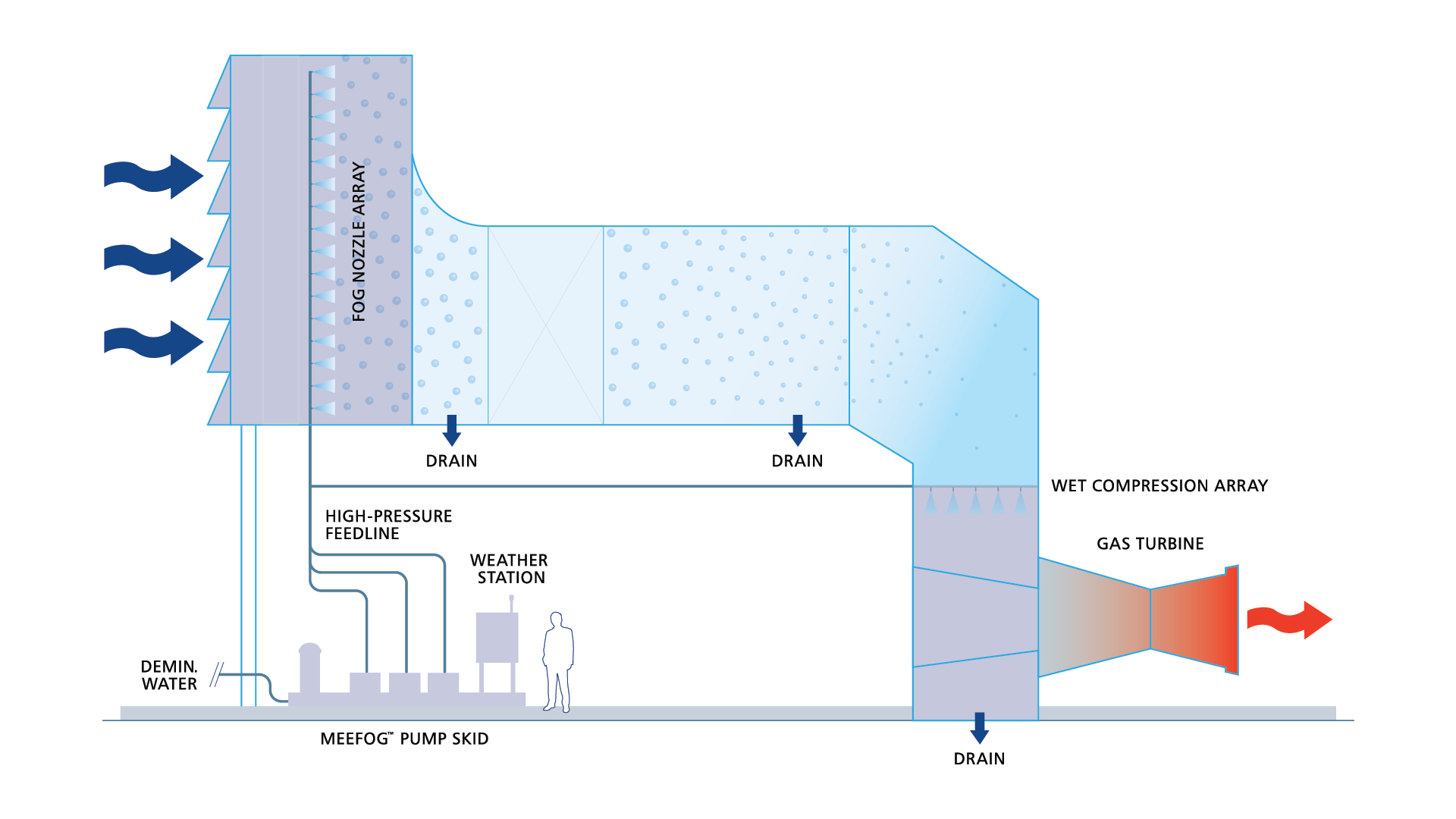

MeeFog GT Installation Diagram

Click the different areas of the diagram below to learn more.

Pump Skid

Pump Skid

Stainless-steel welded frame with oversized inlet water filter. Water lubricated direct drive pumps means no oil or drive belts to change. Variable frequency drives are used to reduce flow for staging.

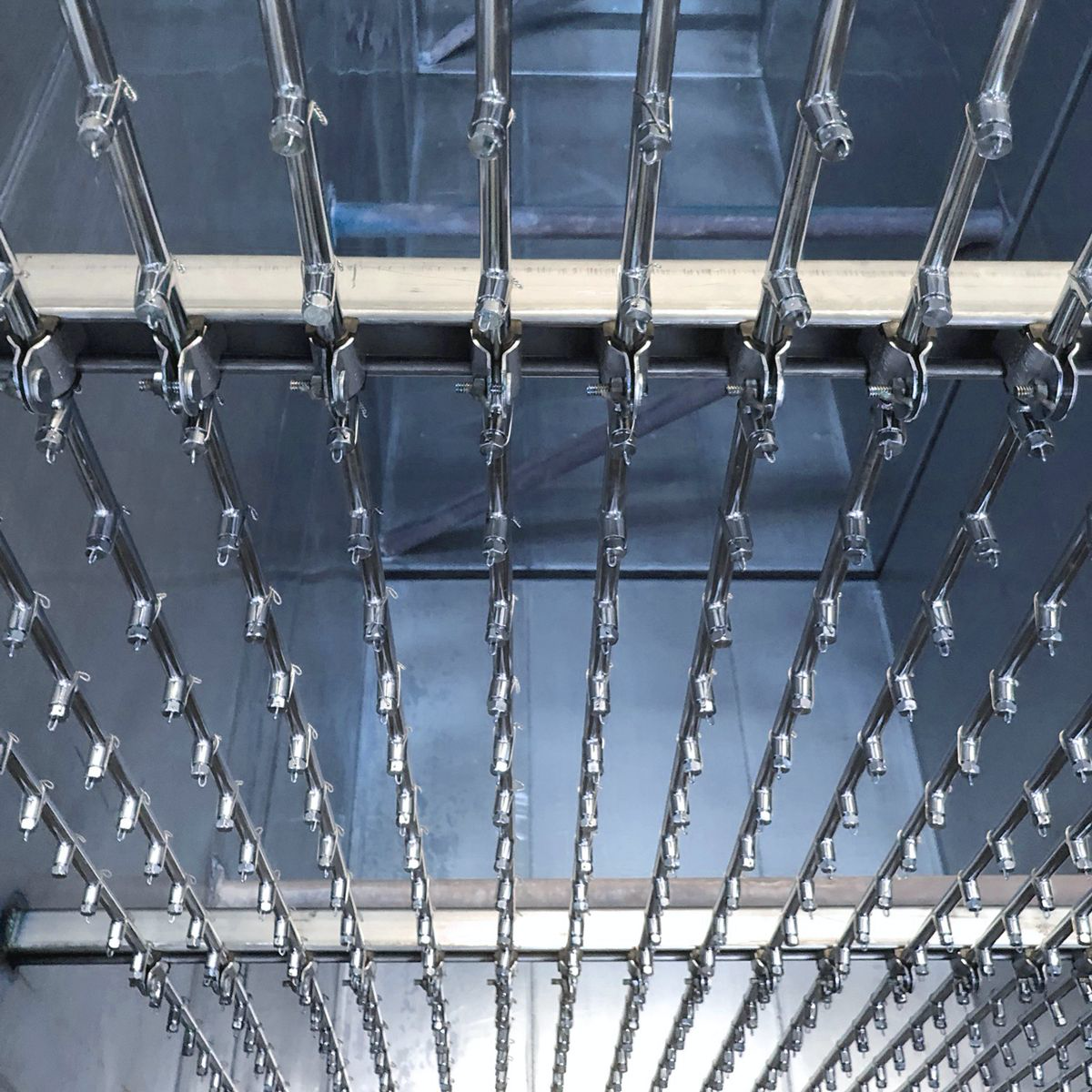

Evaporative Cooling Fog Nozzle Manifold

Evaporative Cooling Fog Nozzle Manifold

Cools to wet bulb temperature with droplets evaporating prior to entering compressor. Fog nozzles mounted on stainless steel tubing are wired for FOD avoidance. These precision nozzles are manufactured and tested in our own facility.

Wet Compression Nozzle Manifold

Wet Compression Nozzle Manifold

Fog droplets evaporate inside the compressor, giving an intercooling effect that reduces the work of compression. Water sprayed into the compressor will reduce NOx as well, but only about half as much as water sprayed into the combustors, because much of the air bypasses the combustion process.

System Overview

Power Boost

MeeFog Gas Turbine Inlet Air Cooling System Benefits

- Fog cooling increases output by 20% or more.

- Overspray fogging provides an additional boost.

- Reduced NOx emissions up to 30%.

- Improved fuel economy.

- Reduced CO2 per kW of power.

- Robust equipment & proven technology.

- Guaranteed results!

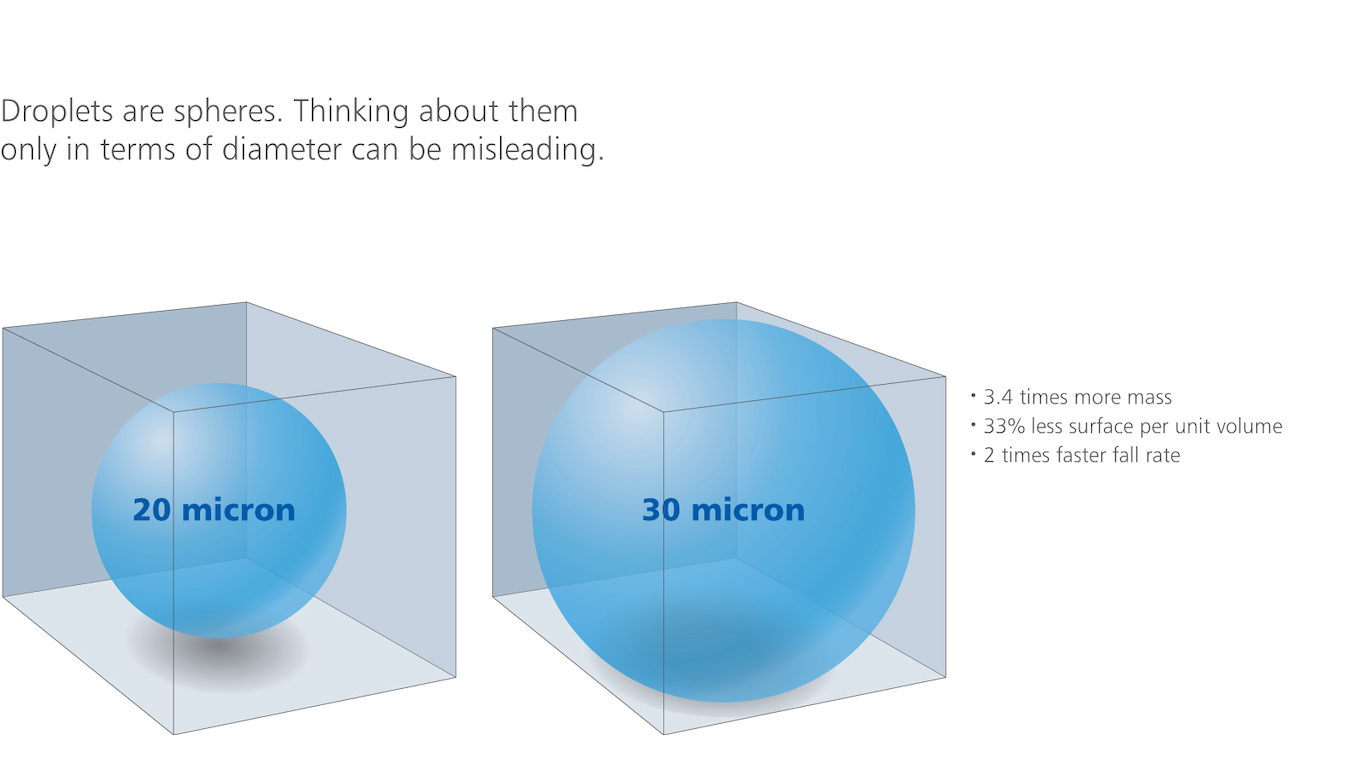

Droplet Comparison

Small droplets have a larger surface-to-volume ratio than large droplets. This increases evaporation speed and cooling performance, making this one of the best inlet air cooling methods for gas turbine applications.

Want Proof?

We’ll gladly supply a detailed power recovery report for your existing gas turbines, including:

- Installed the MeeFog system cost.

- Predicted MW-hr gain per year.

- Fuel savings.

Featured Case Study

MeeFog Gas Turbine Air Inlet Cooling System

How Rapid ROI Pays for Additional Cooling Power

The Challenge

To design the most economical and effective system to increase the power output and improve the fuel economy for 12 ABB combustion turbines.

The Solution

MeeFog Gas Turbine Inlet Air Cooling System was custom-designed and installed to allow fine control over a wider range of temperatures and humidity conditions.

Midland Cogeneration Venture needed a cost-effective way to boost output at its facility. Mee Industries installed an inlet air cooling system to augment power production on six of their ABB11NM gas turbines. One year after the initial installation, Midland Cogen’s Brian Vokal said the results went far beyond expectations. “We are going to buy six more units using the cash generated.” Which is just what they did. As of the summer of 2011, MeeFog skids were installed on all 12 of the plant’s gas turbines.

Gas Turbine Inlet Air Cooling FAQ

Inlet air cooling makes the air denser. Since the compressor of the gas turbine moves a fixed volume of air, the mass flow increases when the air is denser. More mass flow means more power output and improved efficiency.

When you use the inlet air cooling method for a gas turbine, it increases air density, allowing greater mass flow through the compressor. Denser, cooler air requires less compression work, resulting in higher efficiency and output.

A 20°F (11°C) reduction in inlet air temperature can increase output by 10% or more.

Efficiency rises with higher pressure ratios, hotter firing temperatures, or lower compressor workloads. While combustion upgrades help, gas turbine inlet air cooling or wet compression offers a faster, more economical improvement.

Stainless steel nozzles last indefinitely with filtered, demineralized water. Annual visual inspections are recommended to replace any nozzles that show blockage or physical damage.

The MeeFog system’s lifespan is typically 30 years or more. Stainless steel nozzles remain durable indefinitely when used correctly.

Our standard warranty is one year, but we also offer extended warranties. MeeFog gas turbine inlet air cooling systems have a useful life of at least 30 years.

Yes, while the power boost is more significant in dry climates, it remains economically significant even in very humid areas.

ROI varies, but installations often pay for themselves quickly. Midland Cogeneration Venture achieved enough savings from six systems to fund six more within one year.

The gas turbine inlet air cooling system helps reduce NOx emissions by up to 30% and lowers CO2 output per kilowatt of energy produced.

MeeFog Nozzles create droplets less than 10 micrometers, about one-tenth the diameter of a human hair. The small size promotes fast evaporation and uniform cooling before the air enters the compressor.