Gas Turbine Wet Compression Systems

Nearly Instant Power Boost of up to 20%

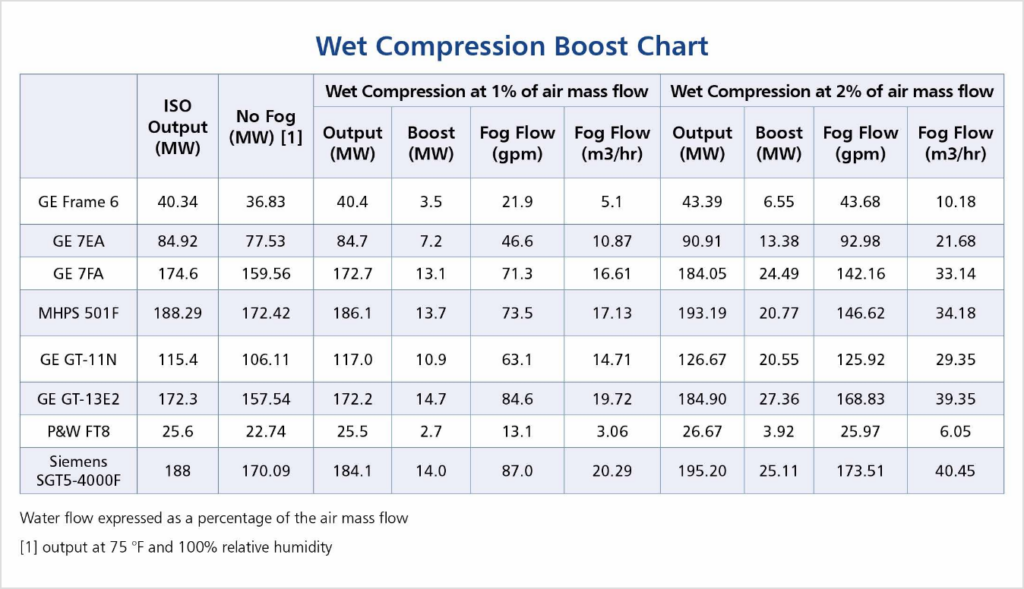

Wet compression is the process of injecting pure water fog into the inlet of a gas turbine engine to boost power output and improve heat rate. In wet compression gas turbine systems, the fine water droplets evaporate inside the compressor, cooling the air and reducing the work required for compression. This effect frees more energy for the output shaft, resulting in higher power production. Every one percent of injected water (relative to air mass flow) can yield a 5% to 10% power boost.

- Droplets evaporate inside the compressor to give an evaporative intercooling effect.

- Spraying 2% of the air mass flow gives up to 20% power boost; systems have been installed that output as much as 2.5% of the air mass flow.

We’ll gladly supply a detailed power recovery report for your existing gas turbines, including:

- Installed system cost

- Guaranteed power gain

- Predicted MW-hr gain per year

- Heat-rate improvement

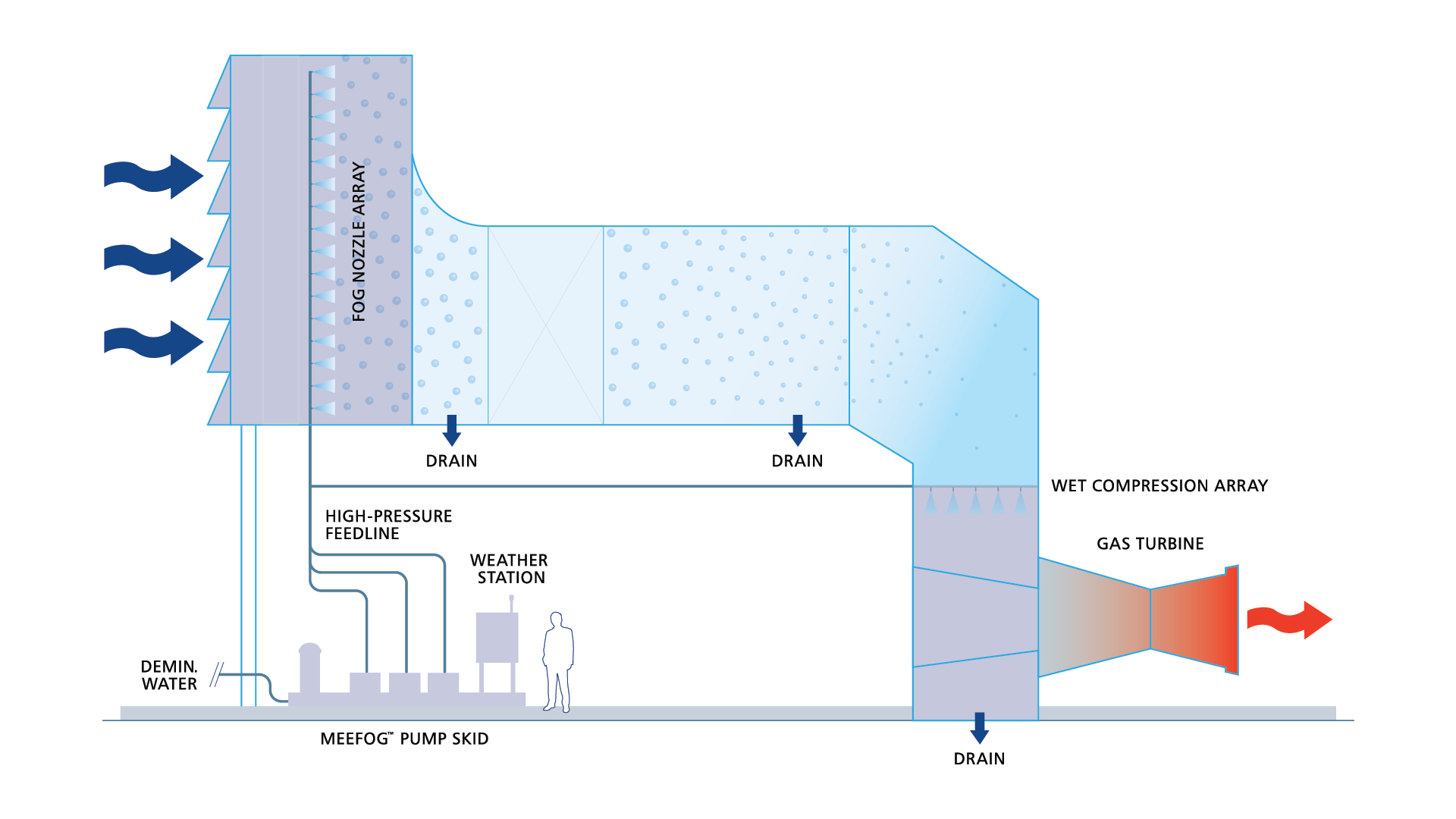

MeeFog GT Installation Diagram

Click the different areas of the diagram below to learn more information about our system.

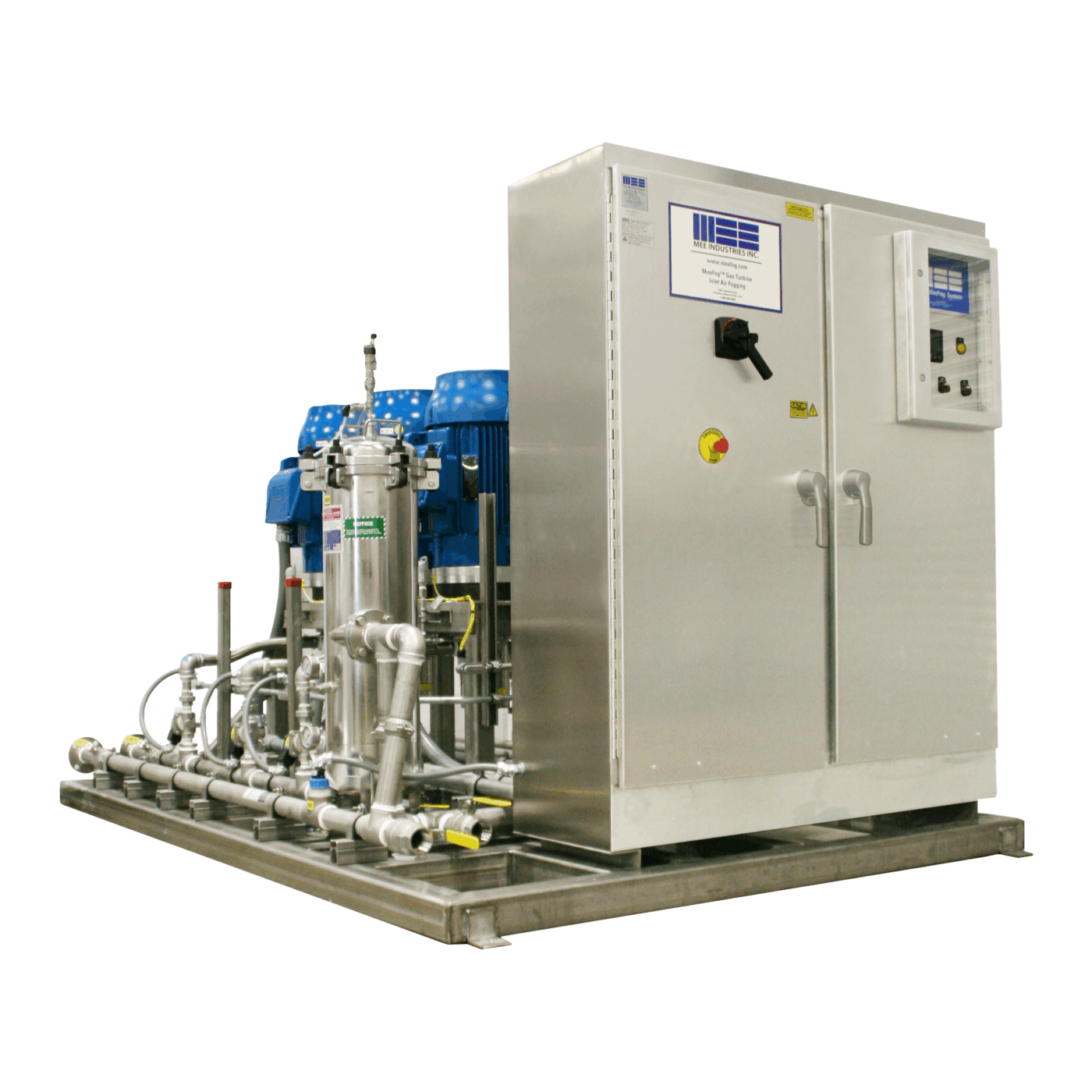

Pump Skid

Pump Skid

Stainless-steel welded frame with oversized inlet water filter. Water lubricated direct drive pumps means no oil or drive belts to change. Variable frequency drives are used to reduce flow for staging.

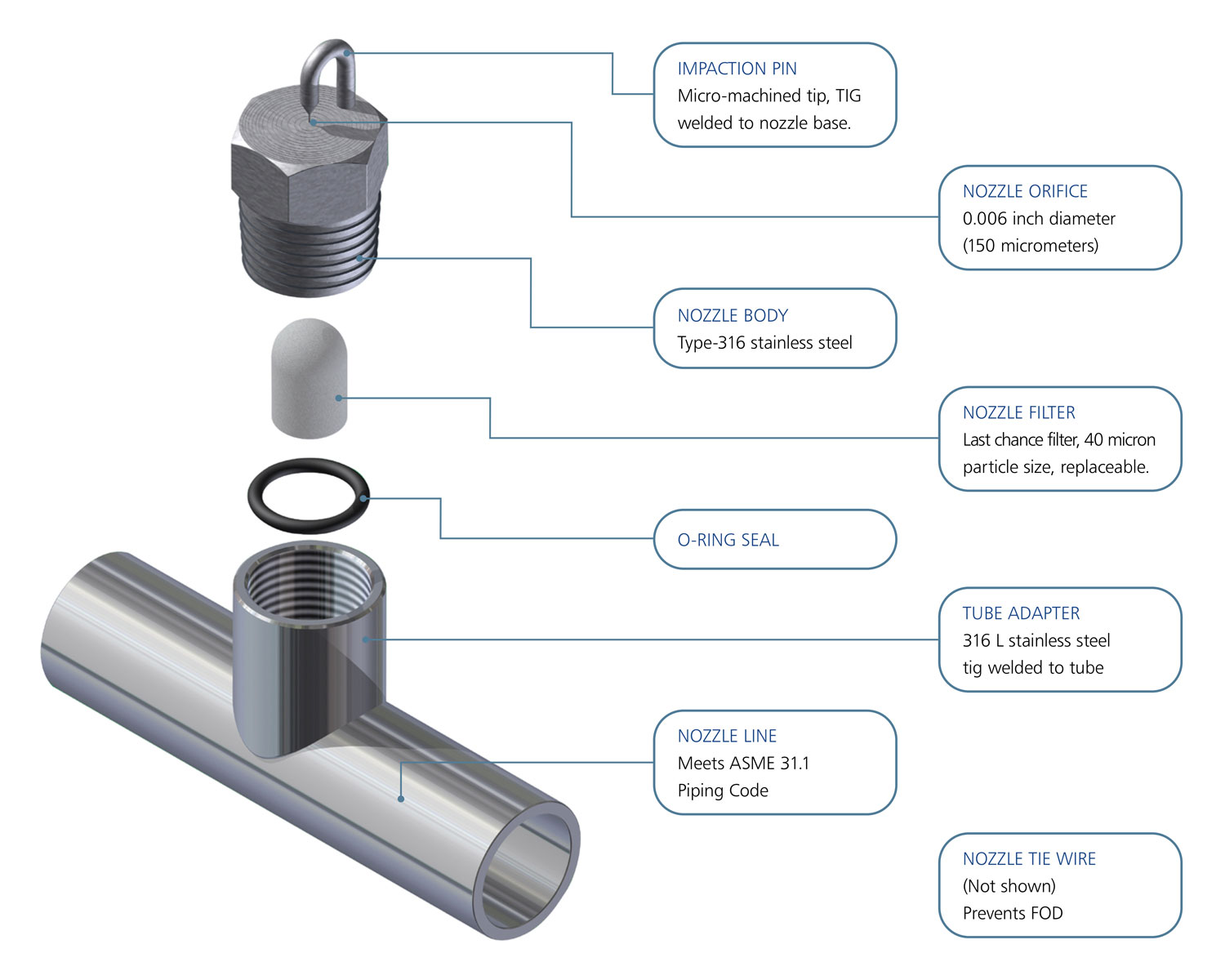

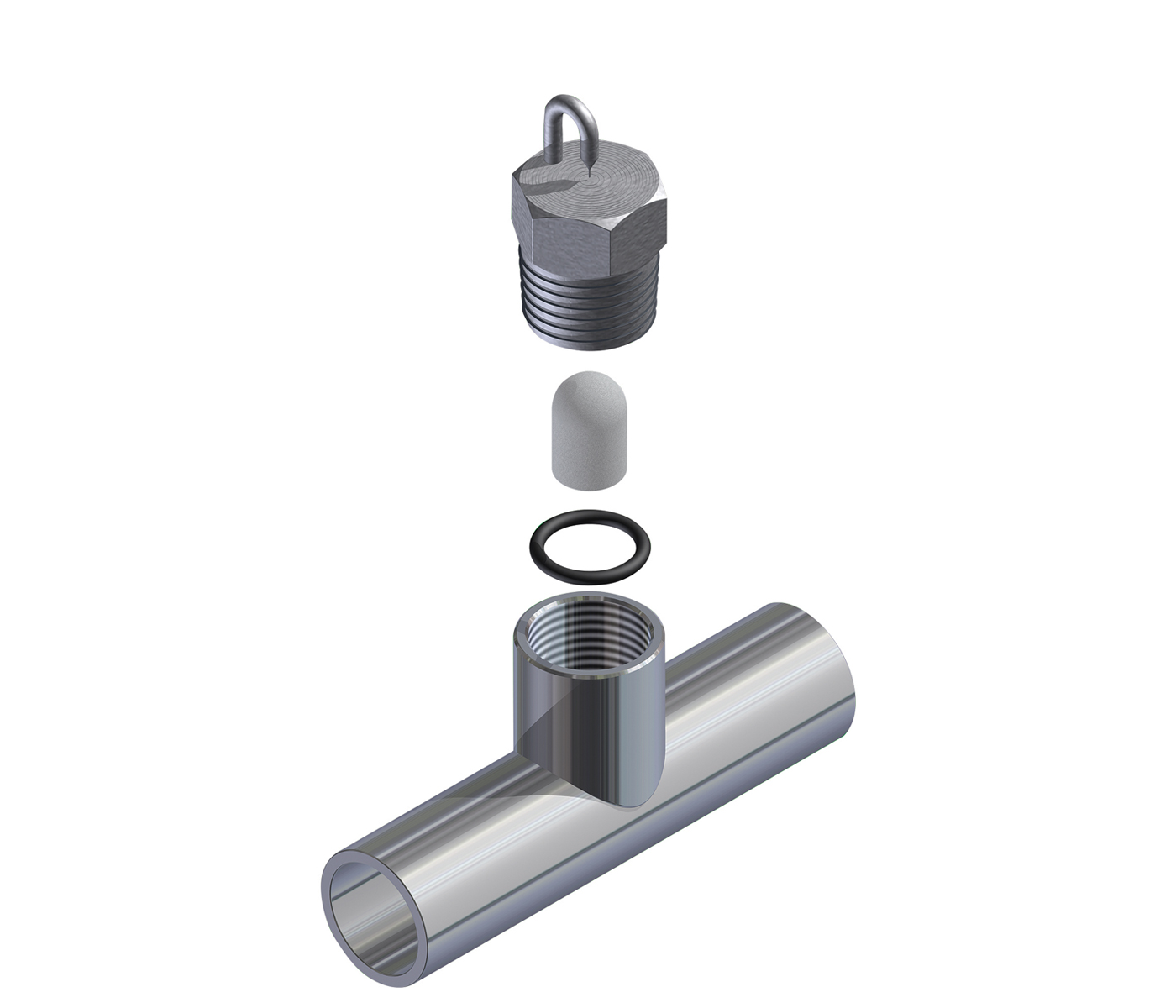

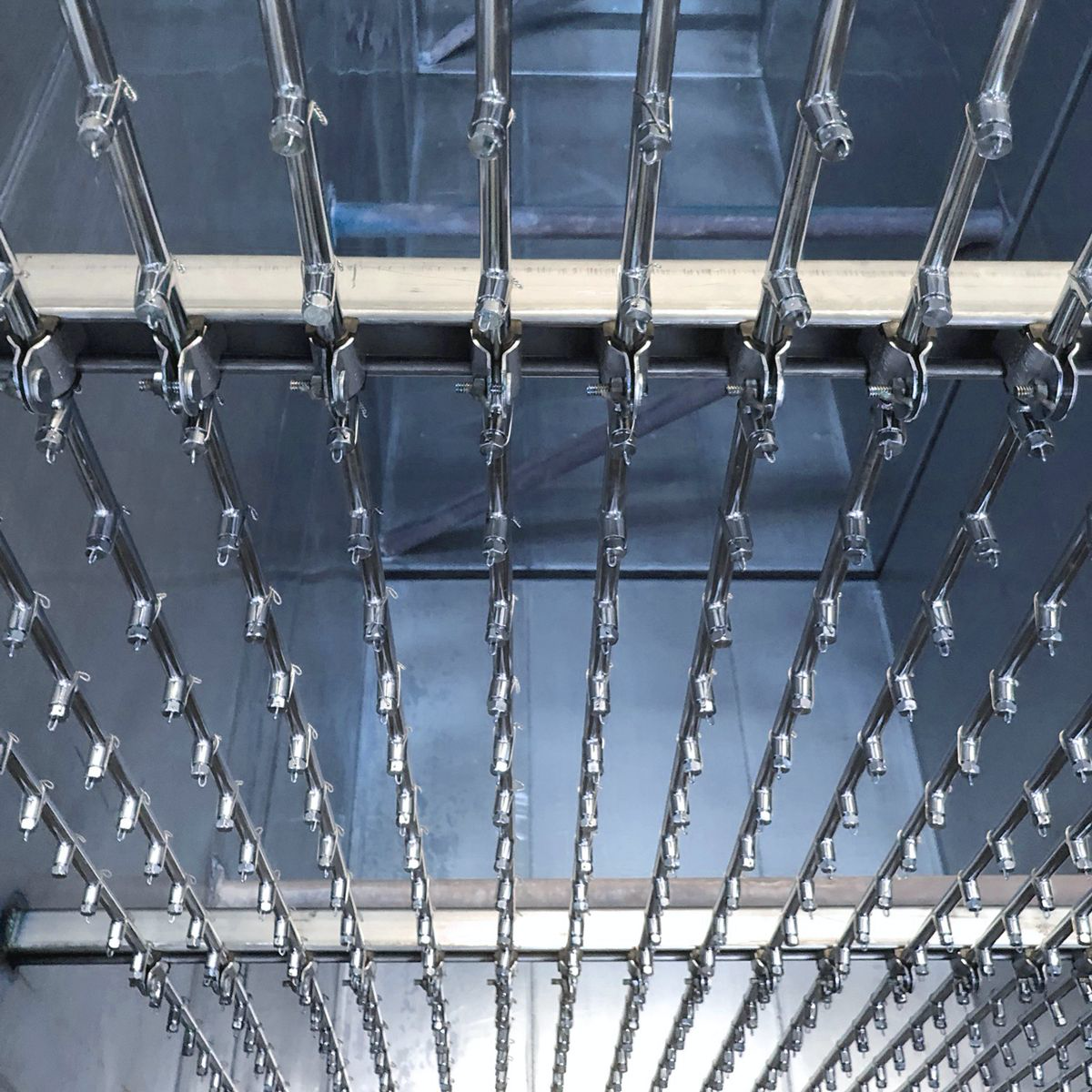

Evaporative Cooling Fog Nozzle Manifold

Evaporative Cooling Fog Nozzle Manifold

Cools to wet bulb temperature with droplets evaporating prior to entering compressor. Fog nozzles mounted on stainless steel tubing are wired for FOD avoidance. These precision nozzles are manufactured and tested in our own facility.

Wet Compression Nozzle Manifold

Wet Compression Nozzle Manifold

Fog droplets evaporate inside the compressor, giving an intercooling effect that reduces the work of compression. Water sprayed into the compressor will reduce NOx as well, but only about half as much as water sprayed into the combustors, because much of the air bypasses the combustion process.

SYSTEM OVERVIEW

Power Boost Chart

MeeFog Gas Turbine Wet Compression System Benefits

- Fog cooling increases output by 20% or more.

- Overspray fogging provides an additional boost.

- Reduced NOx emissions up to 30%.

- Improved fuel economy.

- Reduced CO2 per kW of Power.

- Robust equipment & proven technology.

- Guaranteed results!

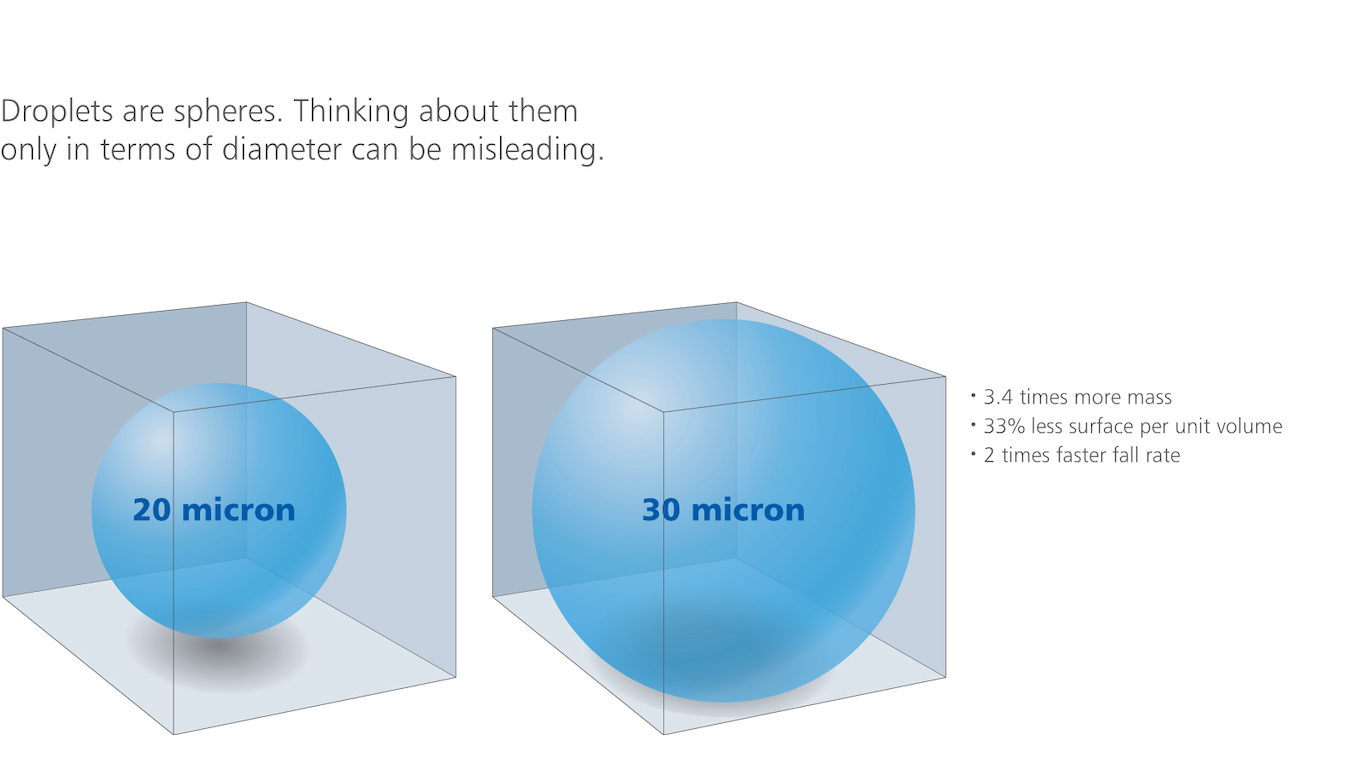

Droplet Comparison

Smaller droplets have a higher surface-to-volume ratio. This allows faster evaporation compared to larger droplets, which is why wet compression is used in gas turbine systems.

Want Proof?

We can supply a power recovery report customized for your wet compression gas turbine setup, including:

- Installed the MeeFog system cost.

- Predicted MW-hr gain per year.

- Fuel savings.

GT Wet Compression FAQ

Wet compression is a gas turbine power augmentation method that injects atomized water (fog) into the compressor. The fog evaporates giving an intercooling effect, which reduces the work of compression and increases available power, further boosted by allowing more fuel to be burned due to cooler discharge air.

It reduces compressor work, freeing more shaft power for useful output, and cools the compressor discharge so additional fuel can be burned and further increasing turbine power.

Injecting a 2% air mass flow as wet compression spray will boost gas turbine output by as much as 10%. The power increase is greater for turbines with a higher pressure ratio.

When correctly implemented, wet compression in a gas turbine operates safely without shortening equipment life.

Yes, many facilities upgrade their existing MeeFog inlet cooling system to include wet compression for additional output, like the Eagle Point Power Generation (EPPG) facility in Westville.

A turbine is likely a very good candidate for wet compression if it operates in conditions above 45°F and has a high pressure ratio. For a customized power recovery analysis of your specific site and turbine, please contact the Mee Industries expert team.

By improving efficiency, it reduces both NOx and CO2 emissions per kW of power produced.

Consumption varies by turbine size and configuration but usually equals 1%–2.5% of the air mass flow.

No, MeeFog wet compression systems are designed for minimal maintenance due to high-quality materials and a simple design.

You should use high-purity demineralized water to prevent fouling and maintain operation reliability.

Featured Case Study

Adding Wet Compression to Existing Fog System

Eagle Point Power Generation – Westville, NJ

The Challenge

When Rockland Capital assumed control of a twenty-year-old combined-cycle plant, the operator sought a cost-efficient method to increase facility performance.

The Solution

Mee Industries added wet compression to the existing MeeFog inlet cooling system. This modification generated an additional 4 MW of power.

The Eagle Point Power Generation (EPPG) facility in Westville, NJ, is a 225 MW combined-cycle plant equipped with two GE Frame 7EA turbines, two Nooter/Eriksen Heat Recovery Steam Generators, and one 50 MW Alstom condensing steam turbine. The site sells power within the PSE&G zone of the PJM market. It began operations in 1991 as a cogeneration plant providing steam to the Eagle Point Refinery, but transitioned to combined-cycle mode after the refinery closed in 2009.