Industrial Humidification Systems

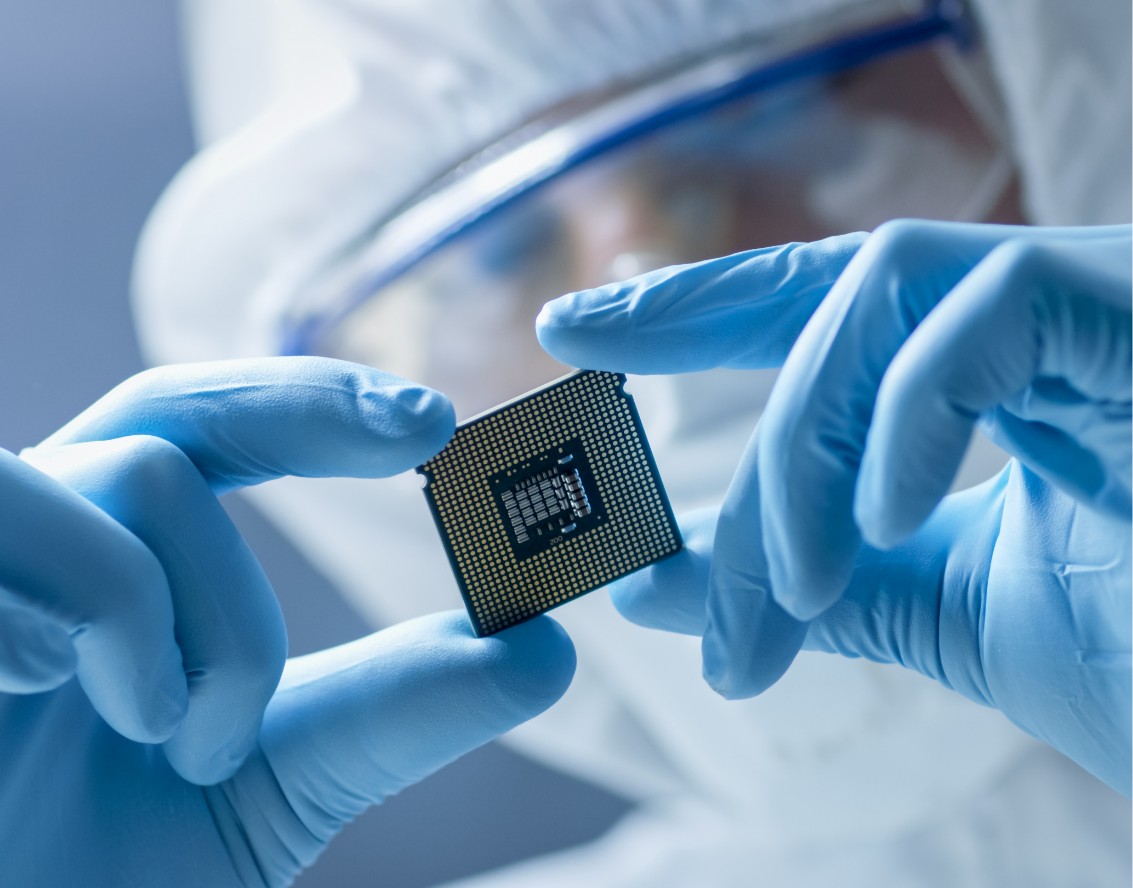

Electronic Component Manufacturing

Production of electronic assemblies and printed electronics typically require a humidified environment. Humidification helps to mitigate electrostatic discharge and reduce rejects due to de-soldering. MeeFog humidification systems offer high-tech solutions that will help improve your process, product and profitability.

Benefits:

• Reduces electrostatic shock.

• Low energy consumption.

• Precise humidity level control.

• Ultra-fine droplets evaporate – no wetting.

Printing Presses

Save energy and improve press speeds with proper humidification in Press Rooms. Applies to all types of printing processes including labeling, containers, and screen printing. Useful anywhere that requires better control of the paper’s moisture content to keep things running smooth. MeeFog can help you eliminate the humidification variable.

Benefits:

• Maintain press consistency.

• Better ink transfer.

• Dimensional stability.

• Reduce rejects.

Woodworking Shops

The moisture content of wood is directly related to the humidity and temperature of the air. Humidification systems help reduce warping, cracking, shrinkage and improper curing of glues and paints by not allowing wood to dry out. Proper humidity control can solve issues with fluctuations in moisture which may cause costly defects.

Benefits:

• Maintain wood moisture content.

• Reduce dust and static control problems.

• Enable product repeatability.

• Lessen down-time.

Shop Floor Humidifiers

The MeeFog system has fogging nozzle lines suspended from the ceiling throughout the plant for manufacturing processes requiring tight humidity control. Having a centralized high-pressure system which is simple and easy to maintain, reduces maintenance costs and increases reliability.

Features:

• Evenly distributed humidification.

• Increased reliability.

• Reduced energy costs.

• Improved product quality.

• Does not require compressed air or steam.

Textile Mills

The control of humidity plays a very important role in the manufacturing process of fabric and knitting. Humidifiers help introduce and maintain optimum moisture levels in your textiles to increase tensile strength of natural fibers and reduce waste. MeeFog systems will provide an ideal environment for your facility by introducing controlled amounts of humidity into the air to obtain optimum fiber conditions.

Benefits:

• Maintain fiber moisture content.

• Increases tensile strength.

• Decrease breakage.

• Reduce static electricity problems.

• Controls cotton fly.

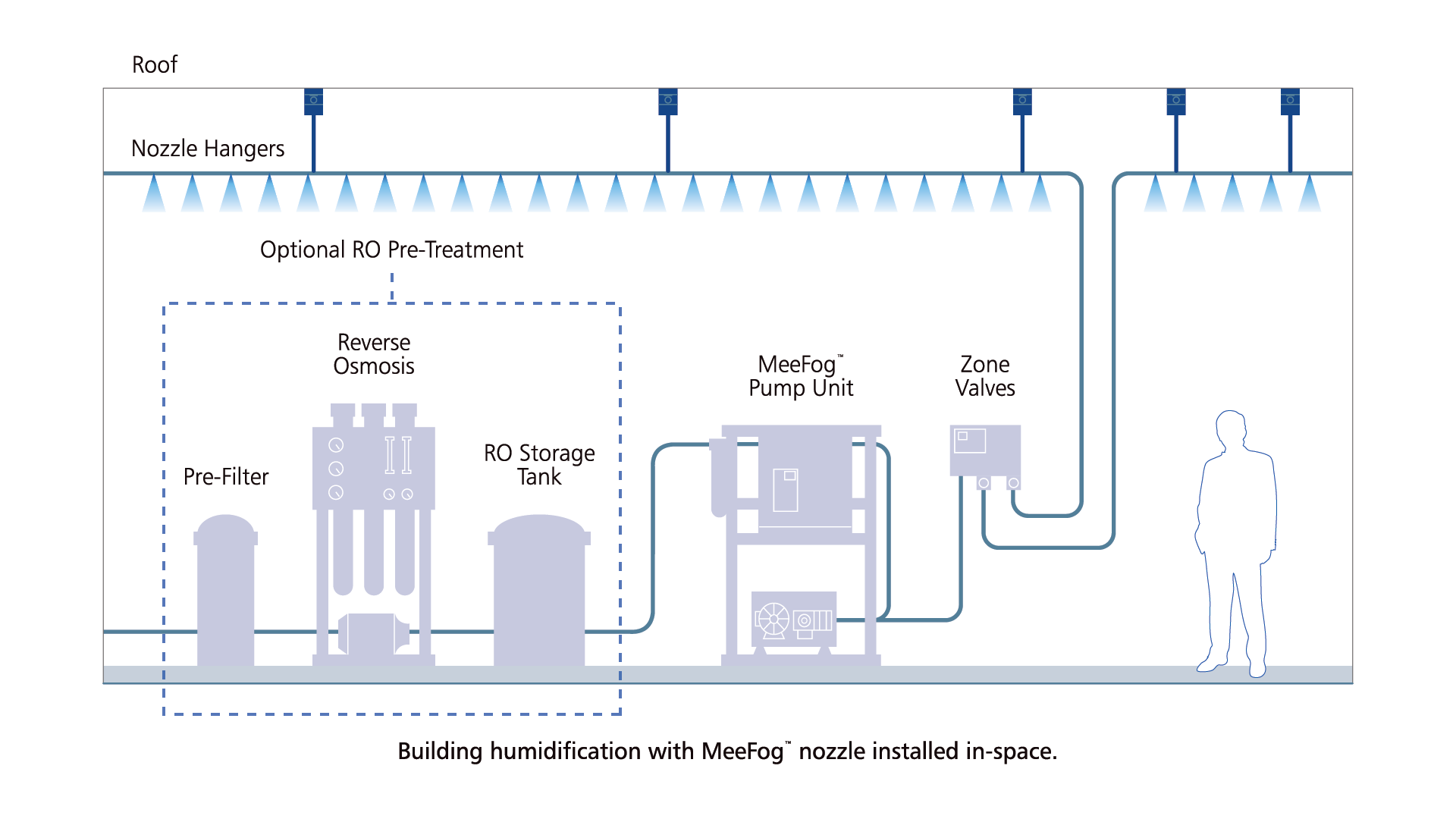

MeeFog In-Space Installation Diagram

Click the different areas of the diagram below to learn more information about our system.

Water Pre-Treatment

Water Pre-Treatment

Basic water treatment, namely, a water softener is required for mineral removal. Based on dust-free requirements for the space additional components including reverse osmosis with automated membrane flushing and pre-treatment filtration can be added.

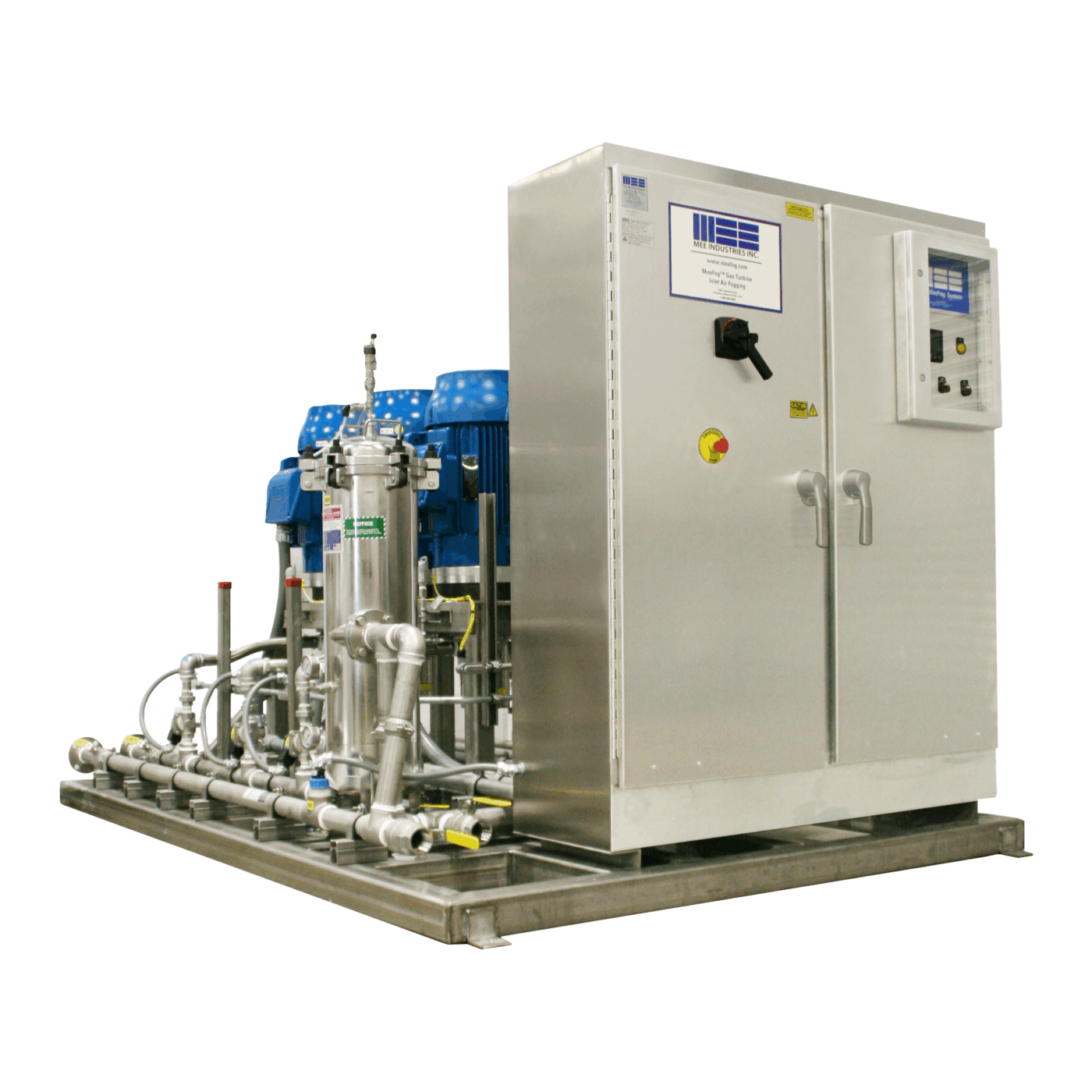

MeeFog Pump

MeeFog Pump

The high-pressure pump maintains 1000 psi water pressure in order to atomize the water into tiny droplets that can evaporate overhead. The pump rack has a VFD with panel-mounted controller that maintains pressure when zone valves open and close.

Zone Valve Panel

Zone Valve Panel

The MeeFog Zone Valve Panel provides control for up to five fogging zones. It can use an on-board humidity sensor or signal from other controllers to actuate ball valves that are slow acting to eliminate water hammer.

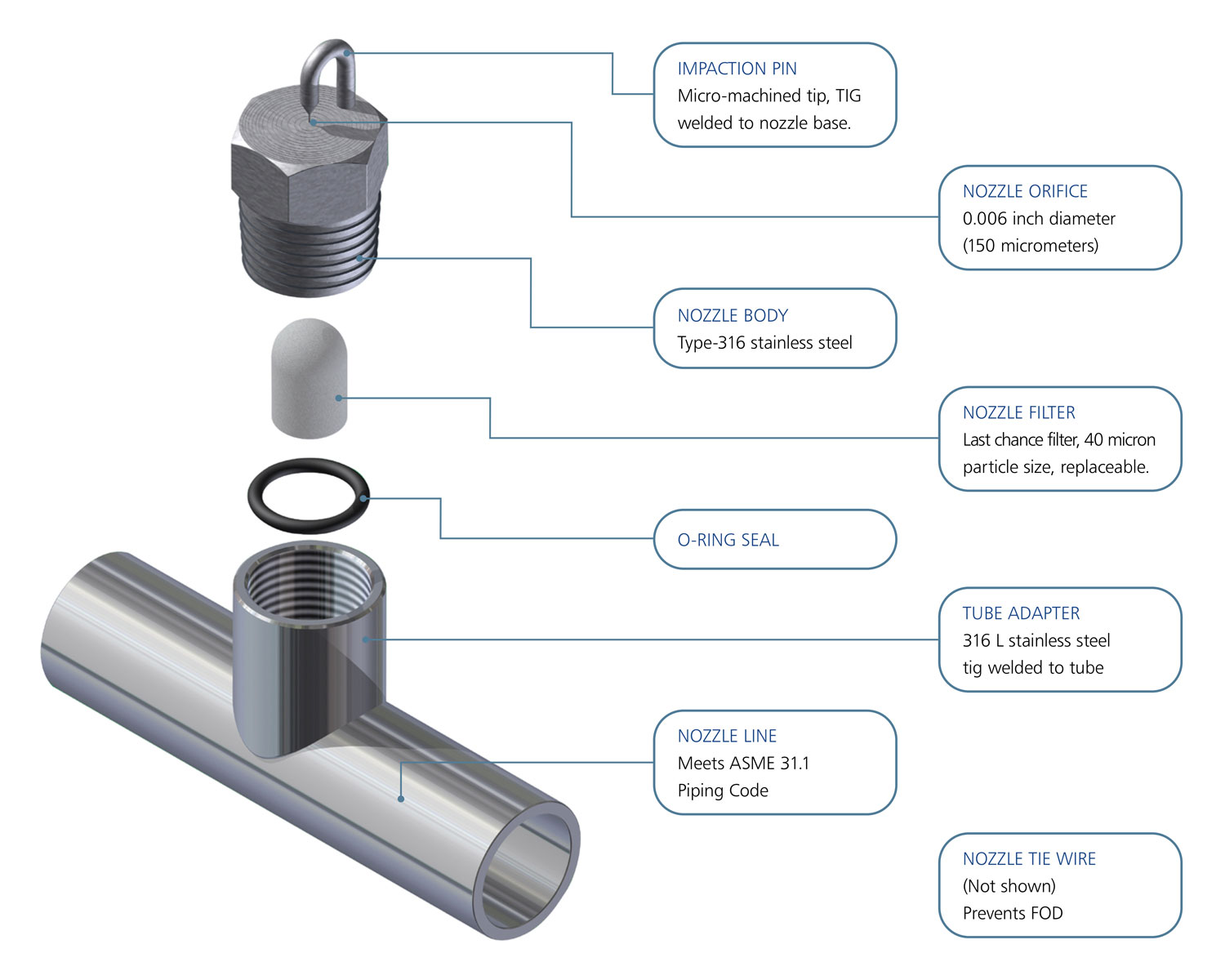

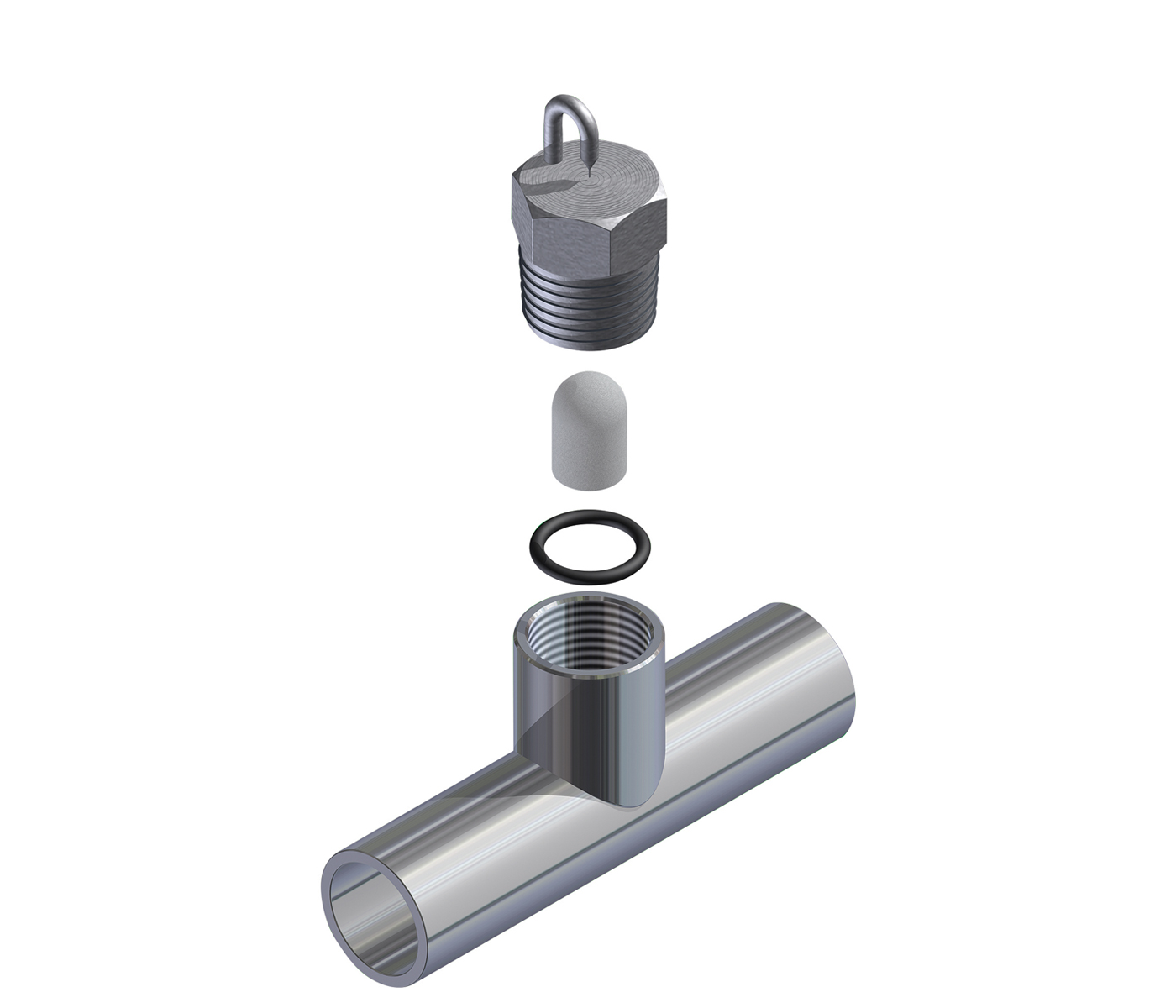

Swirl Jet Nozzles

Swirl Jet Nozzles

The MeeFog Swirl Jet nozzles are stainless steel with a .006” orifice and output 7 lbs. per hour of fog. Fog nozzles mounted on stainless steel tubing can be spaced one per 200 square feet or denser for areas with open bay doors or in need of higher humidity.

System Overview

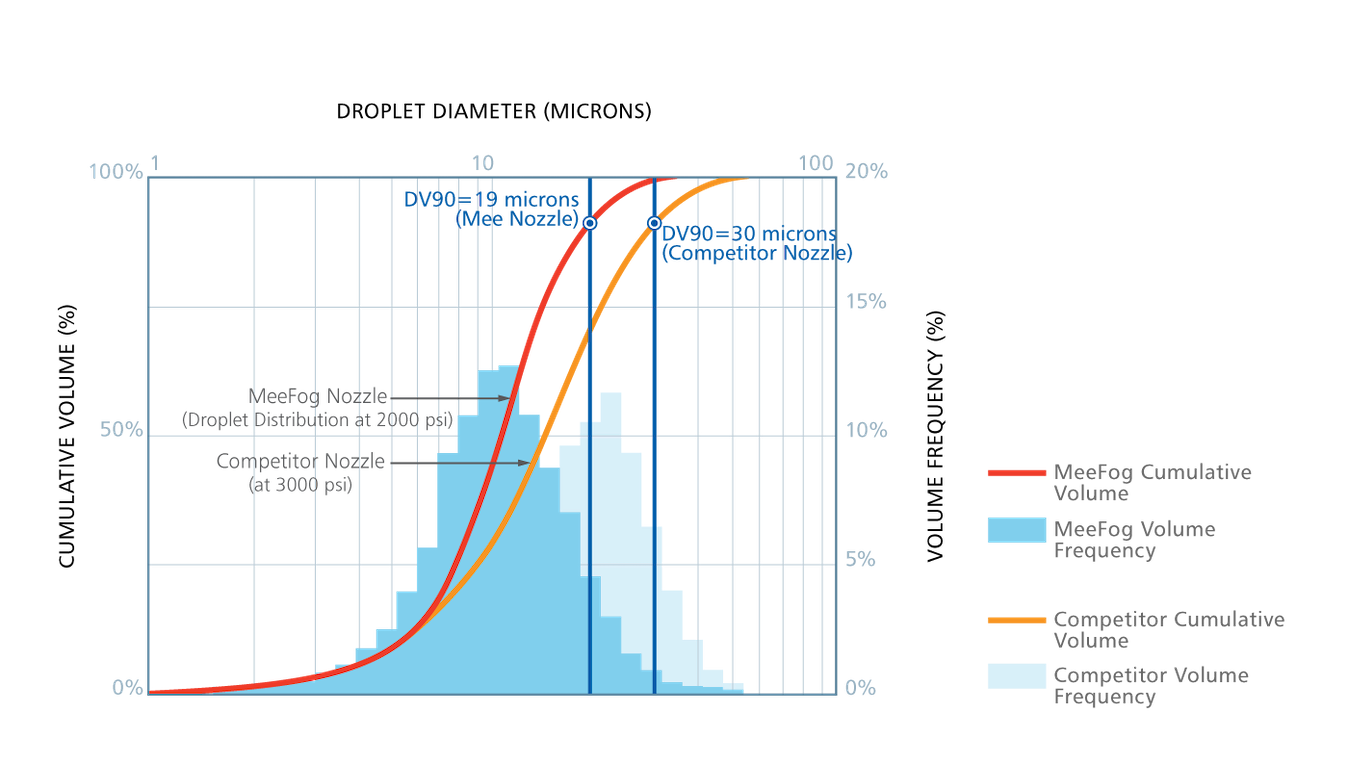

Nozzle Comparison

At an operating pressure of 1,000 psi, the resulting average droplet size is roughly one tenth the diameter of a single strand of human hair.

MeeFog System Benefits

- Minimizes the risk of airborne infections.

- Decreases the occurrence of respiratory issues in newborns.

- Low energy consumption.

- Precise humidity level control.

- Elevates patient and staff overall comfort and virus protection.

- Lowers employee absence rate.

- Reduces premature drying and formation of scabs from coagulated blood.

- Prevention of electrostatic damage to medical equipment.

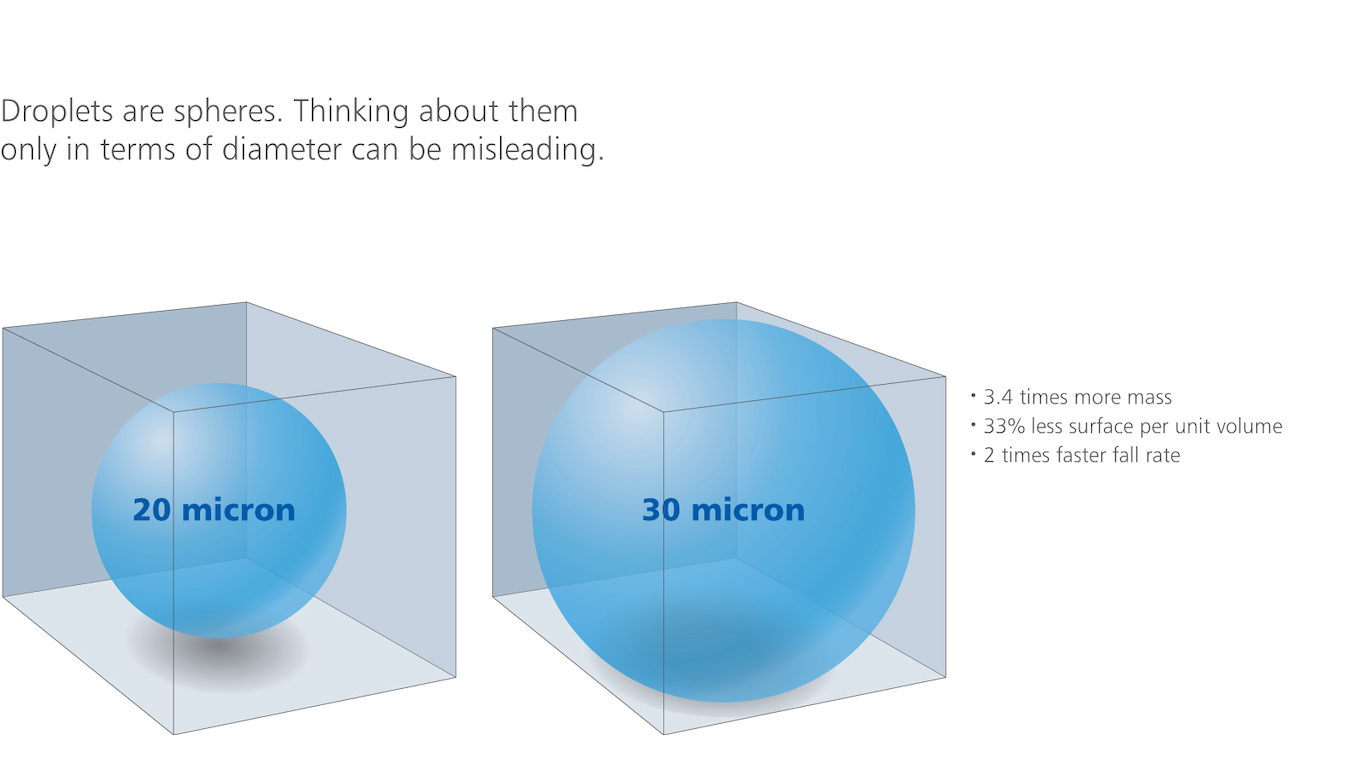

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed payback analysis report for your Hospital or Medical Center including:

- Installed MeeFog system cost.

- Predicted process gains per year.

Humidification for Industry FAQ

In industrial environments, precise humidity control prevents product distortion, static buildup, and production inefficiencies. For example, in paper and packaging production like Dixie Cups, maintaining a steady 45% relative humidity is critical to ensure consistent forming, cutting, and assembly. MeeFog systems deliver reliable humidity levels to keep production lines running smoothly. Facility managers save energy and improve production speeds with humidification for the manufacturing floor.

MeeFog systems offer far lower operating costs than electric steam or compressed air atomizers. A system designed for 1,000 lbs./hr output, running 3,500 hours/year, costs around $700 per year to operate, compared to $14,350 for compressed air atomizers and $128,800 for electric steam humidifiers. That’s a savings factor of up to 180x less energy use while delivering the same humidity output.

MeeFog systems use high-pressure pumps to create ultra-fine droplets, consuming only a fraction of the energy of steam humidifiers. In addition, MeeFog provides adiabatic cooling as it humidifies, reducing the facility’s cooling load and energy bills. This makes MeeFog a dual-benefit solution—improved humidity control plus lower HVAC operating costs.

Dixie Consumer Products needed to maintain 45% RH to prevent cup distortion during forming. MeeFog installed ceiling-mounted nozzle lines across four plant zones, powered by a Model 2500 MFP rack. The result was precise, evenly distributed humidity, improved product quality, and significant cost savings compared to steam or compressed air humidification.

With operating costs as low as $700 per year, MeeFog systems offer a fast payback period—often in 1–2 years depending on plant size and operating hours. The savings come from reduced energy consumption, lower maintenance requirements, and decreased cooling demand. The long-term ROI is further enhanced by improved production quality and fewer humidity-related defects.

Yes. MeeFog humidification systems can be configured for factories, packaging plants, printing, textiles, electronics, and more. Ceiling-mounted nozzles, modular pump racks, and flexible design options allow each installation to be tailored for the facility’s layout and production requirements. This ensures even humidity coverage and maximum energy savings across a wide range of industries.

Featured Case Study

Dixie Cup gets Production Boost from MeeFog System

The Challange:

Dixie Consumer Products opened a new facility for manufacturing of paper cups. The new factory called for precise control of relative humidity to achieve production targets. If humidity is too low the paper cups distort during the forming process. Drew Lee, Engineer for Dixie Cup, explained the secondary process that heats the poly material on the cups and forms an insulated “foam” texture. If the cup is too dry, it won’t form properly.

The Solution:

To control the problem of distortion, the relative humidity (RH) must be maintained at 45%. Dixie Cup installed a MeeFog humidification system for precise humidity control. The ceiling mounted fog nozzle lines are strategically distributed for best coverage.

In 2016 Dixie Consumer Products opened a new 6,300 square foot manufacturing facility in Lexington, Kentucky, which was set up for high volume production of its popular Dixie Cups. Tight humidity control was required to maintain board moisture and avoid distortion, which was a big challenge especially during the colder and drier months.

Mee Industries was contacted to supply a fog humidification system to meet the necessary humidity requirements to help maintain high volume production. Dixie has defined four areas of the plant for distinct operations, and each area was brought online separately using the Meefog model 2500 MFP rack and four high pressure solenoids.