Understanding Atomizing Fog Nozzles for Evaporative Cooling

Blog

Evaporative cooling is used in industrial and power generation systems and can help reduce operating costs and improve efficiency. Fog systems work by atomizing water into fine droplets that evaporate to absorb heat from the surrounding air.

In this article, we examine how atomizing fog nozzles work in more detail, measurement techniques for accurate droplet sizing, and performance implications for industrial applications.

What is Fog and Artificial Fog Generation

Natural fogs form when moist air cools and water vapor condenses into a cloud of small droplets. Fogs can also form when warm, moist air mixes with cooler air. If the resulting mixture’s temperature is below its dew point, fog droplets will form.

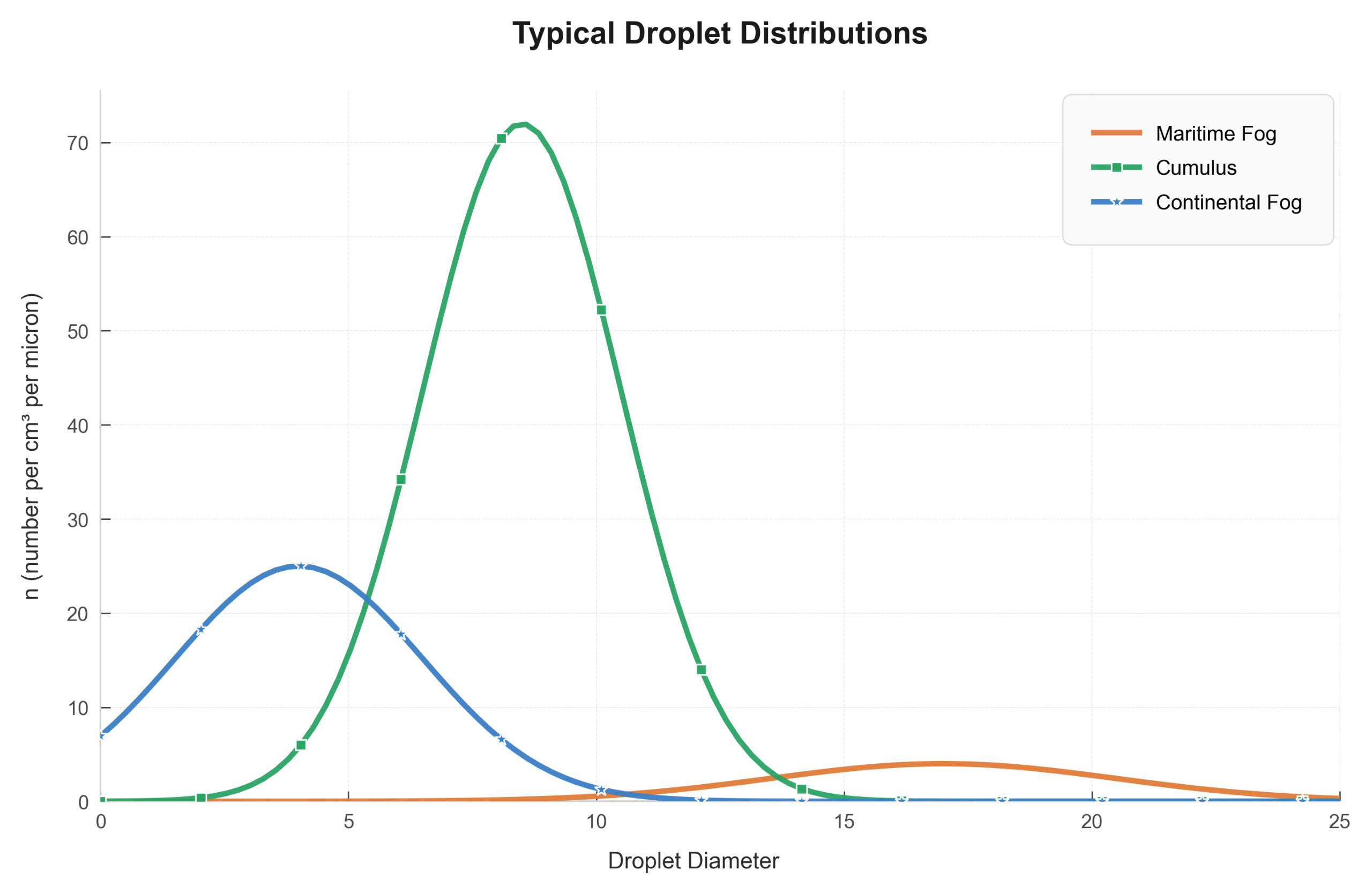

Here are the different fog types and characteristics:

- Fogs that form over land tend to consist of droplets with a diameter of 20 microns or smaller

- Marine fogs typically have larger droplets, but fewer droplets per volume of air

- Cumulus clouds generally have droplets of 15 microns or smaller, and a high droplet population density

Artificial Fog Generation Methods

Artificial fogs can be created through three primary methods, each with its own energy requirements and applications.

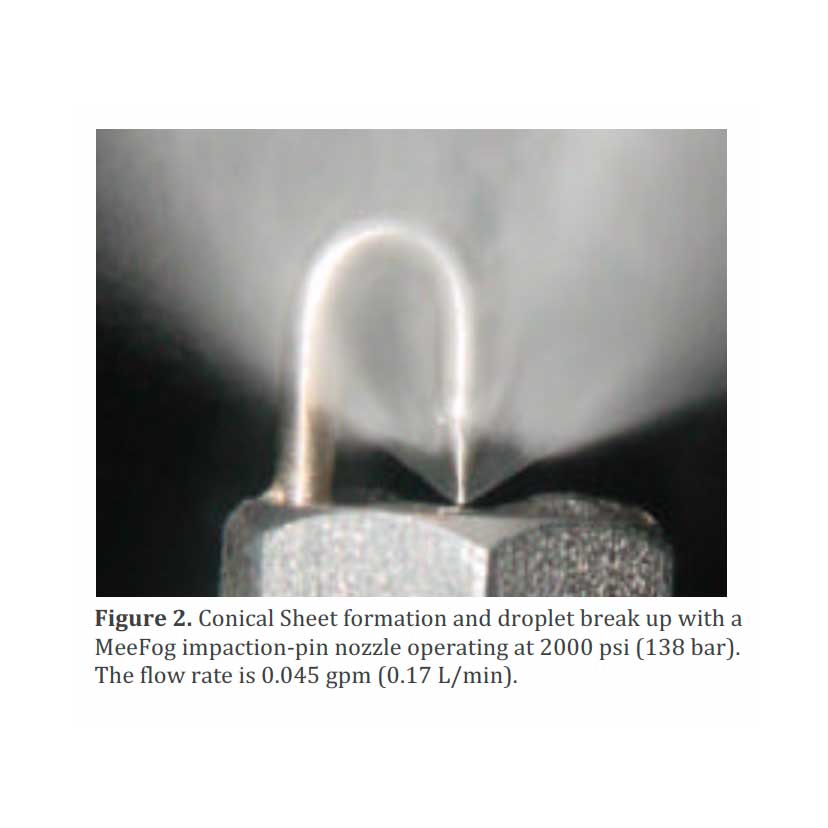

High-pressure atomization creates fog by forcing pressurized water through specially designed spray nozzles that form expanding conical sheets of water. As these sheets expand and thin, they break apart into small droplets.

Compressed-air nozzles can produce small droplets by using high-velocity air jets that shatter water streams. However, they are not suitable for producing large volumes of fog because compressing air requires about 30 times as much energy as high-pressure fog nozzles.

Piezo-electric atomizers use a piezo-electric crystal to vibrate a bath of water at very high frequency. They use about 10 times as much energy as high-pressure fog nozzles, so they are not suitable for creating large volumes of artificial fog.

In industrial evaporative cooling systems, high-pressure atomization is the practical choice because of its superior energy efficiency and ability to produce large volumes of fog required for effective cooling.

How High-Pressure Fog Nozzles Work

Atomizing fog nozzles create an expanding conical sheet of water. As the sheet expands, it thins. At a short distance from the orifice, aerodynamic forces overcome surface-tension forces, and the sheet breaks apart into small droplets and ligaments.

Aerodynamic forces further break the ligaments, and water surface tension causes the resulting droplets to become spherical.

The Weber Number and Pressure Effects

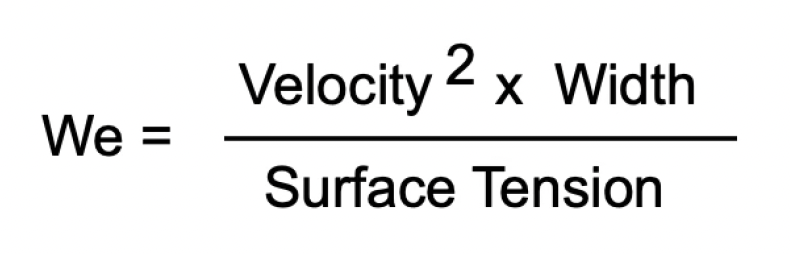

The atomization process itself is complex, but for purposes of comparing fog nozzle performance, it’s enough to know that the droplet size produced is inversely proportional to the Weber number (We). It’s presented with this equation:

The velocity term in the numerator is squared, so the magnitude of the Weber number depends mostly on the velocity of the conical sheet. This velocity depends on the nozzle’s liquid pressure, its orifice diameter, and the internal friction that can slow the water jet.

At high pressure (2000 psi), the conical sheet breaks up quickly, producing smaller droplets due to higher velocity. At lower operating pressure (1000 psi), the conical sheet extends farther from the orifice and becomes thinner at breakup. However, the droplet size is larger because the lower velocity results in a much smaller Weber number.

After the initial breakup, the droplets and ligaments still have high velocity, so aerodynamic forces can cause larger water particles to break up again. This secondary breakup happens at a lower velocity because drag forces have slowed the particles, resulting in a larger droplet size. This process explains why atomizing nozzles tend to produce a range of droplet sizes.

Droplet Collisions and Coalescence

Near the nozzle orifice, the droplet population density is high. Droplets of different sizes are also present, and all are moving at high velocity relative to the airflow. Larger droplets retain their velocity longer because they have more momentum, whereas smaller droplets slow down quickly due to aerodynamic drag.

Larger, faster-moving droplets collide with the smaller, slower-moving droplets, so they coalesce to form larger droplets. Droplet collisions mostly occur within 10 to 20 centimeters (4 to 8 inches) from the orifice.

When atomizing nozzles are operated in a moving airflow, the air turns the smaller droplets sooner, so they occupy different flow paths from the larger droplets. This means there are fewer collisions and less droplet coalescence. For this reason, the average droplet size produced by a fog nozzle gets smaller as the velocity of the surrounding airflow increases.

Types of Atomizing Fog Nozzles

There are two types of air atomizing nozzles that are used with industrial fogging systems: impaction-pin nozzles and swirl-jet nozzles.

Impaction-Pin Nozzles

Impaction-pin nozzles have straight-through orifices with less flow resistance.

The spray from an impaction-pin nozzle appears more opaque and whiter because smaller droplets backscatter light more effectively, and the spray plume is less defined because smaller droplets can follow micro-turbulence in the airflow.

Image: IP nozzle operating at 2000 psi (69 bar)

Swirl-jet (SJ) nozzles produce an expanding conical spray plume by passing the water through flow paths inside the nozzle, which forces the water to exit the nozzle tangential to the axis of the orifice.

The existence of the internal flow paths means the flow through a swirl-jet nozzle is reduced somewhat as compared to impaction-pin nozzles.

With the swirl-jet nozzle, the larger droplets have more momentum, so the edge of the spray plume is sharper, and the spray is grayer in color and more transparent because there are fewer droplets and the larger droplets scatter less light.

Image: SJ nozzle with a similar flow rate operating at 2000 psi (69 bar)

Visual Differences and Orifice Size Effects

The difference in droplet size between the two nozzle types can be seen with the naked eye. At a given operating pressure, atomizing nozzles produce smaller droplets when they have smaller orifices. The smaller orifice means the water velocity is higher, so the Weber number is higher, and the droplet size is smaller.

However, an impaction-pin nozzle with a deep orifice will have more frictional loss and a slower water jet, so the droplet size will be larger. Likewise, a swirl-jet nozzle with a longer flow path will have more frictional losses, so it will produce larger droplets.

Spray Angle and Air Flow Dynamics

The spray angle of the impaction-pin nozzle is greater than 90 degrees, but the resulting spray plume does not continue to spread out at 90 degrees from the orifice. This narrowing of the spray plume happens because the fast-moving droplets pull air along with them. So, air is evacuated from the center of the spray plume, and that results in lower air pressure in the center of the plume, and air flowing into the plume pushes the spray closer together.

Larger droplets are less affected by the air flowing into the plume, so the edges of the plume tend to have larger droplets, while the center of the plume has smaller droplets.

Measuring Droplet Size Accurately

Droplet size is usually measured with a laser particle analyzer. One common type is a laser diffraction device.

Malvern Spraytec Particle Analyzer

The instrument measures the intensity of light that is diffracted (forward scattered) at different angles as the laser beam passes through the spray. The angle of diffraction is proportional to droplet size.

Concentric circles of photodiodes are positioned on the opposite side of the spray plume from the laser source. They detect the intensity of laser light at different angles, which determines the size and number of droplets that pass through the laser.

Measurement Challenges

Because of the effects of droplet collisions and coalescence, it’s important to measure droplet size far enough downstream of the nozzle orifice so the increase in droplet size is accounted for.

Furthermore, since most of the larger droplets will be found on the edges of the spray plume, accurate droplet measurement requires scanning the measurement laser through the entire spray plume.

Another type of laser particle analyzer is a phase-doppler instrument. These instruments have a measurement volume that is defined by the intersection of two small-diameter laser beams, which means it has a small sample volume.

If the phase-doppler instrument is focused at the center of the spray plume near the nozzle orifice, it would yield an average droplet size that is much smaller than the true droplet size of the entire spray.

If droplet size is not measured using proper techniques, the results can be very misleading. For example, if the laser is focused at the middle of the spray plume, close to the orifice, an average droplet size of 10 microns might be found, whereas if the proper technique is employed, the average droplet size might be 30 microns or larger.

ASME Power Testing Code 51

In the early 2000s, Mee Industries tested dozens of nozzles using a laser particle analyzer in a wind tunnel.

After extensive experimentation, we derived droplet measuring techniques that led to the development of the ASME Power Testing Code 51, Appendix A, Droplet Size Testing Protocol.

The testing protocol includes the following requirements:

- Droplet size measurements must be performed in a wind tunnel in fully humidified air upstream

- Droplet size measurements should be taken in an airflow with a velocity that is close to the airflow velocity at which the nozzles will be used.

- Droplet size must be measured progressively further from the nozzle orifice until the droplet size stops getting larger.

- The laser beam of the particle analyzer must be scanned through the entire spray plume so that all the droplets are measured.

This protocol establishes a uniform method for comparing different nozzles accurately.

Why Droplet Size Matters

Droplets are spheres, so doubling their diameter causes an eight-fold increase in the mass of the droplet and therefore in the force of impact if it strikes a surface such as a gas turbine compressor blade, but only a four-fold increase in surface area.

Liquid impaction erosion occurs when droplets of sufficient mass strike a surface. If the droplets are large enough, they can cause microfractures in the metal surface, which results in pitting.

Mathematical Relationships

For example, eight 10-micron droplets contain the same mass of water as one 20-micron droplet, but the 10-micron droplets expose twice as much surface area of water to the air. Therefore, a given mass of water atomized into 10-micron droplets will evaporate much faster than if it were atomized into 20-micron droplets.

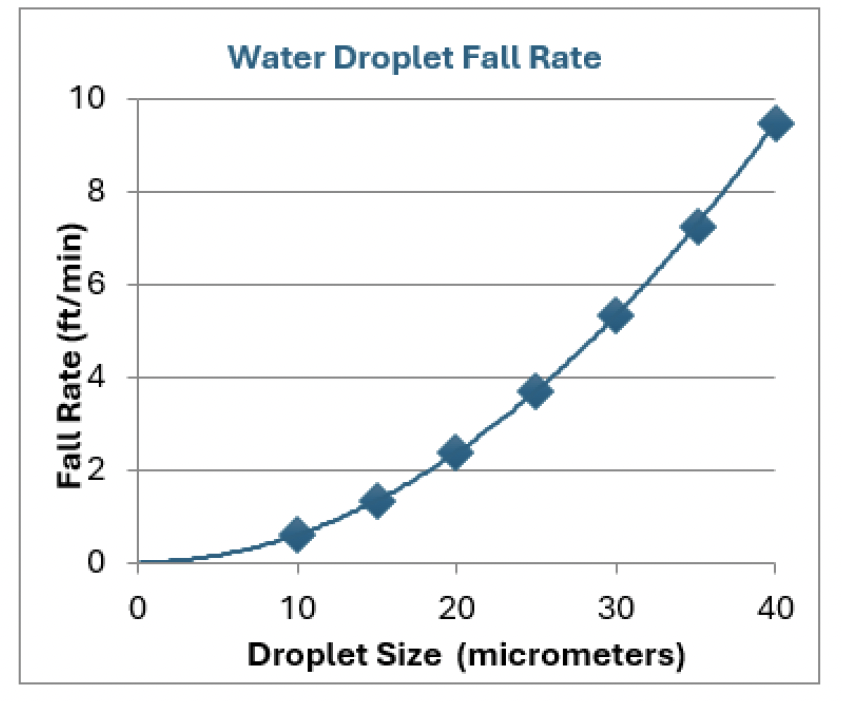

Small droplets also fall exponentially slower than larger droplets, which means they are more likely to evaporate before falling to the ground. A 30-micron droplet falls about twice as fast as a 20-micron droplet.

Here’s a graph for the water droplet fall rates.

Droplet Size Metrics

There are many different droplet size metrics. Average droplet size is an obvious one. Another is mass-mean diameter. It’s the diameter of a droplet that has the same mass as the average.

Sauter Mean Diameter helps evaluate evaporation processes because it tells how much water surface area is exposed by the spray.

For gas turbine fogging, where avoiding blade erosion is important, Mee Industries recommends using a Dv90 droplet size. This representative diameter gives a droplet size for which 90% of the spray is in droplets that are smaller than or equal to the stated diameter.

Predicting Nozzle Performance and Applications

Using the technique described above, Mee Industries found that nozzles of a given type will produce a droplet size that can be accurately predicted from the flow rate and operating pressure, regardless of the manufacturer of the nozzle.

The charts shown below can be used to determine the Dv90 droplet size produced by different fog nozzles operating at 2000 psi in a 500 ft/min airflow.

Droplet size for different nozzles at 500 ft/min airflow velocity (SI units).

These performance charts demonstrate clear relationships between nozzle flow rate and droplet size for both impaction-pin and swirl-jet nozzles.

The data shows that impaction-pin nozzles consistently produce smaller droplets than swirl-jet nozzles at the same flow rates. For example, at a flow rate of 0.05 gpm, impaction-pin nozzles produce approximately 24-micron droplets while swirl-jet nozzles produce approximately 34-micron droplets.

Real-World Applications

Gas turbine inlet cooling and wet compression applications require precise droplet size control. MeeFog systems have been installed on over 80,000 MW of gas turbine capacity, with over 1,000 systems installed worldwide. The power boost from these installations exceeds 8,000 MW.

For inlet cooling systems, droplet size control prevents equipment damage while maximizing evaporation efficiency. Wet compression applications benefit from the ability to predict droplet behavior, allowing engineers to optimize spray rates for specific turbine models. Mee Industries’ experience covers gas turbines ranging from 5 MW to 250 MW, including work with gas turbine OEMs.

Economic Benefits

The manufacturer-independent nature of these performance relationships provides flexibility in system design and supplier selection.

The return on investment for installing a MeeFog system can be realized in less than 1 year. Engineers can select appropriate nozzle types and operating parameters before installation, reducing both installation costs and long-term maintenance requirements.

Conclusion

Atomizing fog nozzles produce droplet sizes that can be accurately predicted from flow rate and operating pressure. However, proper droplet measurement and nozzle selection make the difference between effective cooling and equipment damage.

Your MeeFog representative can assist with selecting appropriate atomizing nozzles and optimizing system performance for your specific cooling and humidification needs.