MeeFog Systems Cut Bird Flu Risk with Poultry Disinfection Fogging

BlogPreparing for the Fall/Winter 2025 Bird Flu Upsurge:

Minimizing the Chance of a Poultry Outbreak through Improved Sanitation

Proper poultry sanitation is essential for minimizing bird flu outbreaks on modern farms.

Recent statistics from the CDC and USDA indicate two things:

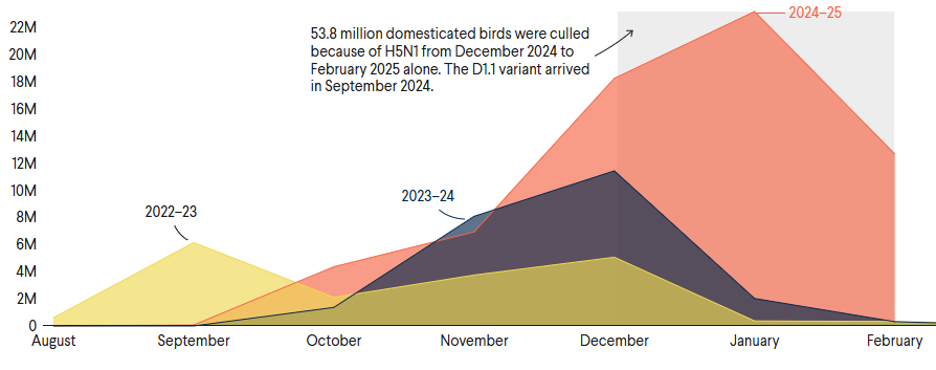

- A year-by-year increase in the quantity of birds impacted by bird flu – from a little over 6 million in the highest month of 2022/2023 to more than 10 million for the highest month of 2023/2024, and more than 22 million in a month in the current year.

- Variable frequency based on climate: Summer heat greatly reduces outbreaks while cooler fall and winter temperatures tend to precipitate a rise in reported cases

It is reasonable to predict, therefore, that the Fall of 2025 is likely to signal another rash of outbreaks with it peaking in the late winter. Thus, the poultry industry would be wise to take steps now to prepare.

One relatively simple action to take is microbial cleaning to leave viruses and bacteria no place to hide. While this approach alone does not guarantee elimination of bird flu, it helps to minimize the chances of an outbreak.

Bird Flu Basics

Bird flu (also known as avian influenza or by its technical names of H5N1 highly pathogenic avian influenza or HPAI) is a specific strain of the influenza virus. It is a highly contagious respiratory disease that primarily affects birds, but can also infect other animals, including mammals like dairy cows and humans. It can be fatal for chickens.

The number of detections between December 2024 and February of 2025 were about four times more than in those months during the previous winter. USDA estimates around 170 million birds have been culled from poultry flocks across all 50 states since 2022. The problem has spilled over to other areas. More than 1,000 dairy herds across 17 states have reported cases over the past year as well as a small number of people who were directly in contact with diseased animals.

While bird flu hasn’t attracted much in the way of mainstream headlines, one of its consequences has very much been in the news – high egg prices. U.S. Bureau of Labor Statistics for March of 2025 put the average price of a dozen eggs at nearly $6, up a $1 on the previous month. The price has dropped in recent months but all it takes is one more outbreak for prices to spiral once again.

Part of the reason for more outbreaks (and higher egg prices) has been the emergence of a new bird flu variant in recent months, according to poultry and bird flu veterinarian David

Swayne from Watkinsville, Georgia. Result: USDA reports the depopulation of 33.5 million birds in the first four months of 2025 along with 43 outbreaks in 10 states. A May case in Arizona impacted 2.3 million birds. Ohio, though, is the worst affected state. It accounts for more than 40% of all 2025 losses.

Bird flu is increasing in frequency each year. Based on CDC data.

“We lost about 3,000 birds on our farm during the winter,” said Marty Thomas, owner of Kakadoodle Farm.

The whole flock had to be destroyed and the farm came under a USDA 120-day quarantine. Sales crashed due to the unavailability of eggs. Fortunately, the farm survived on its other revenue stream – selling produce from local farms via a farm shop and online sales. Nevertheless, revenue slumped by thousands a week for a couple of months. The good news in this case is that media attention generated so much interest that sales rebounded after the quarantine.

Bird Flu Mitigation

The US Department of Agriculture has stepped in with a $1 billion-dollar strategy to curb HPAI, protect the U.S. poultry industry, and lower egg prices. This is in addition to funding already being provided to indemnify growers for depopulated flocks.

“American farmers need relief, and American consumers need affordable food,” said U.S. Secretary of Agriculture Brooke Rollins. “To every family struggling to buy eggs: We hear you, we’re fighting for you, and help is on the way.”

The program includes Wildlife Biosecurity Assessments to producers across the nation, beginning with egg-layer facilities, to safeguard farms from the cause of 83% of HPAI cases: transmission from wild birds. Across 150 facilities that follow these protocols, only one had an outbreak. Free biosecurity audits are available for all HPAI-affected farms. Surrounding, non-affected farms also qualify for free audits.

These audits result in actions that need to be taken to safeguard the farm. To soften the financial blow, the USDA will share up to 75% of the costs to fix the highest risk biosecurity concerns identified by the assessments and audits. Producers whose flocks must be depopulated to control the further spread of HPAI will be indemnified.

How to Improve Farm Sanitation

Improving the Effectiveness of Cleaning and Sanitation

The USDA actions with biosecurity will certainly help to reduce the spread of bird flu by limiting the introduction of disease from wild birds. But resources are limited and who knows where the next outbreak will occur.

One way to minimize the chances of an outbreak is improved hygiene. When an area is power washed, for example, residual waste is left behind which acts as a breeding ground for bacteria and the spread of disease. If the poultry environment is regularly disinfected and harmful bacteria and viruses are eliminated, the spread can be contained. All areas in contact with animals must be properly cleaned and sanitized. That extends to trucks, trailers, feeders, and waterers.

poultry fogging system

Microbial Restoration Services LLC of Gurnee, IL, has developed a greener alternative to traditional chemical-based cleaners. Its microbial cleaner uses beneficial bacteria which naturally digest waste and convert it into carbon dioxide and water. It gets into tiny cracks, crevices and the pores of a surface to break down feces, urine, dirt, and grime. This enables it to be digested at a microscopic level and converted into a non-hazardous material. Known as Mr. Eats-it FOGFU, this microbial cleaner can be used on walls and floors to thoroughly clean and area prior to disinfecting.

“Cleaning alone is not sufficient to eliminate the risk of bacteria and viruses,” said Talbot.

He recommends that poultry facilities be cleaned with Mr. Eats-It FOGFU followed by being thoroughly disinfected using Sani-Powder, a 600 ppm hospital grade Hypochlorous Acid (HOCL). Made from salt and water, HOCL is said to be 100 times stronger than bleach yet is not harmful to humans or animals. It also doesn’t corrode or degrade surfaces due to its neutral pH.

To maintain a virus-free environment for livestock, regular use of the microbial cleaner and HOCL disinfectant will be needed. It is essential to disinfect feeders, waterers, and tools daily with Sani-Powder even while livestock are present. It can also be used to disinfect walls, vaccination needles, workers’ clothing, and shoes. As it is not a chemical, it will not leave any film or residue when it dries. It is EPA, FDA, N List approved commercial grade disinfectant.

Fogging Systems vs Spraying as a Disinfection Solution

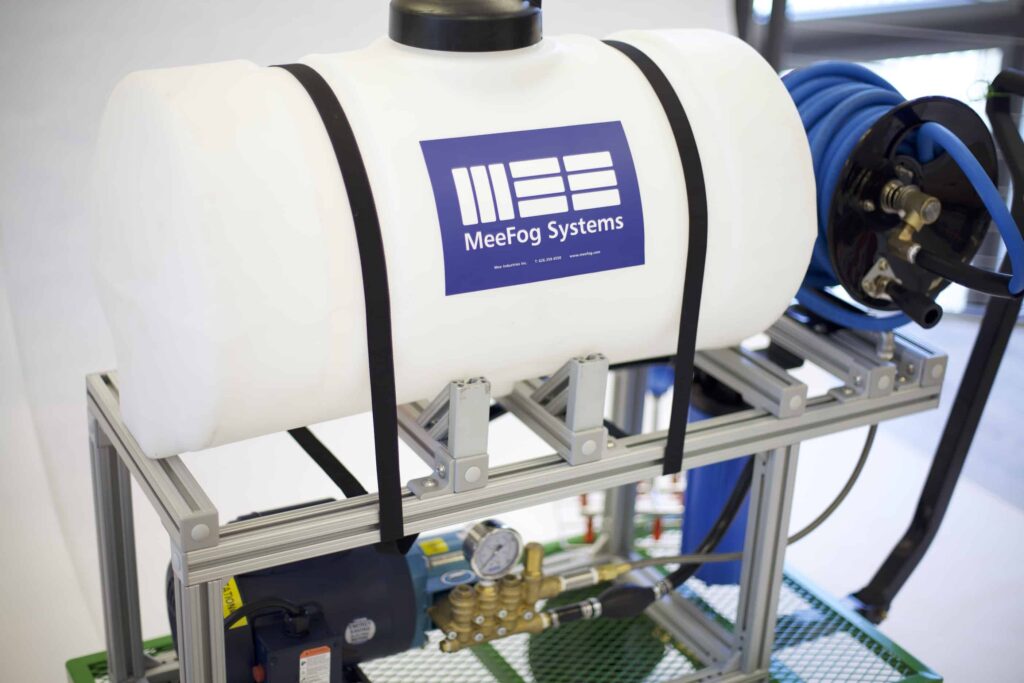

Talbot looked around for the best fogger and found the MeeFogger System from Mee Industries of Irwindale, California. Using a MobileMee Fogging system, one operator can project a dense fog of micro-fine droplets that extends for twenty feet or more. This empowers that operator to accomplish the workload of ten compared to using other spray systems.

“Already used heavily in agriculture and to sanitize buildings from COVID-19, the MeeFogger covers large areas rapidly and thoroughly,” said Talbot. “It can transmit our disinfectant to all areas of a poultry operation.”

The MobileMee spraying system greatly reduces the labor involved in spraying a livestock or agricultural area. Courtesy of Mee Industries.

Microbial Restoration Services devised the combination of Mr. Eats-It FOGGU and Sani-Powder along with fog-based spaying in what it calls the Clean, Kill and Prevent (CKP) system.

The entire disinfecting and fogging system is portable. A five-gallon solution tank delivers 600 ppm of hypochlorous acid pressurized up to 2,000 PSI. A 50-foot or 100-foot hose extends from the unit to the high output nozzles of the MobileMee sprayer that covers an entire area in minutes. It applies a film over all surfaces

“A thick fog is produced that forms a uniform, microscopic layer on sprayed surfaces, ensuring maximum coverage of our bacteria-killing hypochlorous acid,” said Talbot. “This saturation allows the fog to get everywhere air flows including under tables, objects on shelves, behind toilets, cargo areas and food storage areas.”

Why MeeFog Makes a Difference for Poultry Biosecurity

- Enhanced Disinfection: MeeFog’s micro-fine fog reaches all areas of a poultry facility, ensuring thorough coverage and eliminating hidden viruses and bacteria.

- Efficient & Cost-Effective: The system dramatically reduces labor and disinfectant usage, making cleaning faster and more affordable for farm operators.

- Proven Biosecurity: Used together with EPA-approved Sani-Powder, MeeFog provides a hospital-grade level of sanitation, helping to minimize the risk of bird flu outbreaks.

- Portable & Easy to Use: With its mobile design and high-output nozzles, MeeFog adapts to a variety of farm layouts and biosecurity needs.

- Peace of Mind: Regular use of advanced fogging and cleaning systems like MeeFog helps protect both flock health and farm profits, even during high-risk bird flu seasons.

How Mee Industries’ MeeFog Systems Work

- Delivers ultra-fine, 10-micron fog droplets for total facility coverage.

- Reaches hidden areas—ensuring thorough disinfection of all surfaces.

- Minimizes labor and chemical use for cost-effective operation.

- Maintains a clean, healthy environment to protect flock health and farm revenue.

- Quick, portable setup with user-friendly controls.

- Energy-efficient and designed for reliable, long-term performance.

- Easy to maintain and built for demanding farm conditions.

Contact Us

Mee Industries specializes in custom-engineered, turn-key high-pressure fog systems trusted by leading farms worldwide. Our expert team is ready to answer your questions, discuss your unique needs, and provide the most reliable fogging technology available. If you are interested in a MeeFog system please contact us to request a quote or for more information about how our solutions can help protect your operation from bird flu outbreaks.