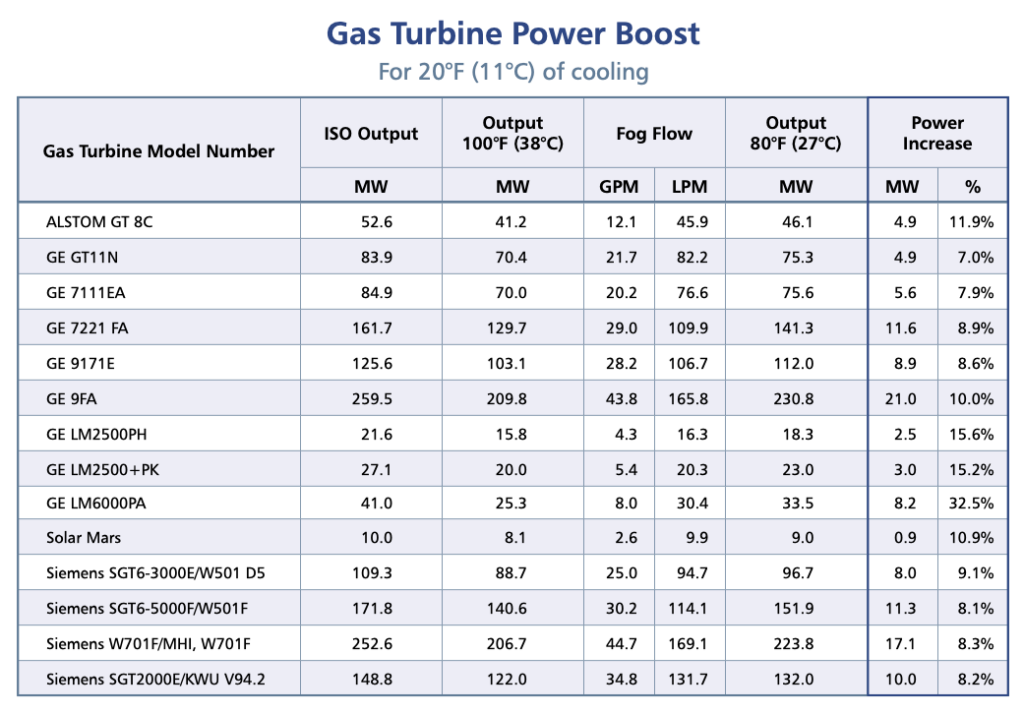

Gas Turbine Inlet Air Cooling

Boost Power with the Cost-Effective Meefog System

We’ll gladly supply a detailed power recovery report for your existing gas turbines including:

- Installed system cost.

- Guaranteed power gain.

- Predicted MW-hr gain per year.

- Improve heat rate up to 5%.

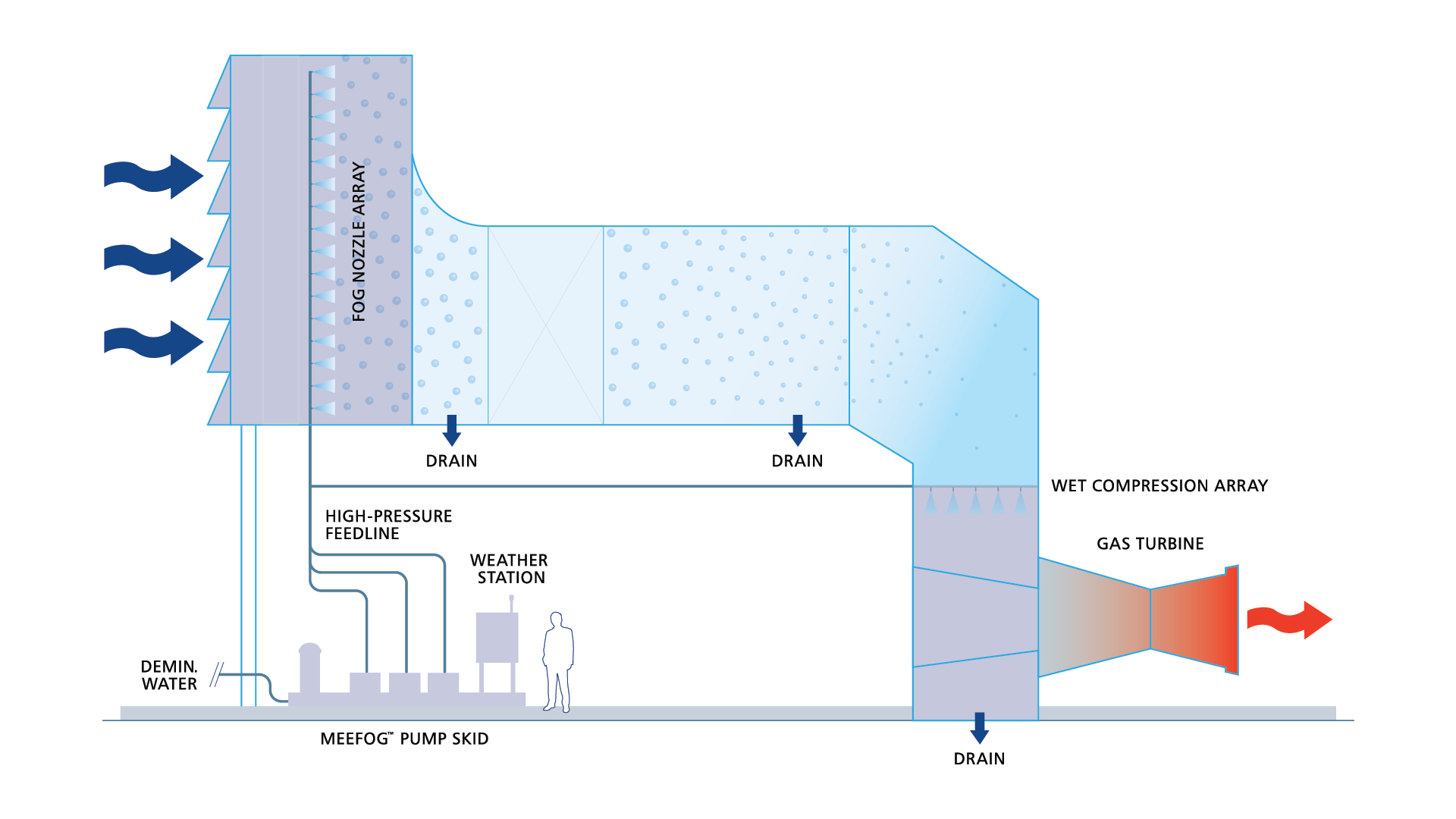

MeeFog GT Installation Diagram

Click the different areas of the diagram below to learn more.

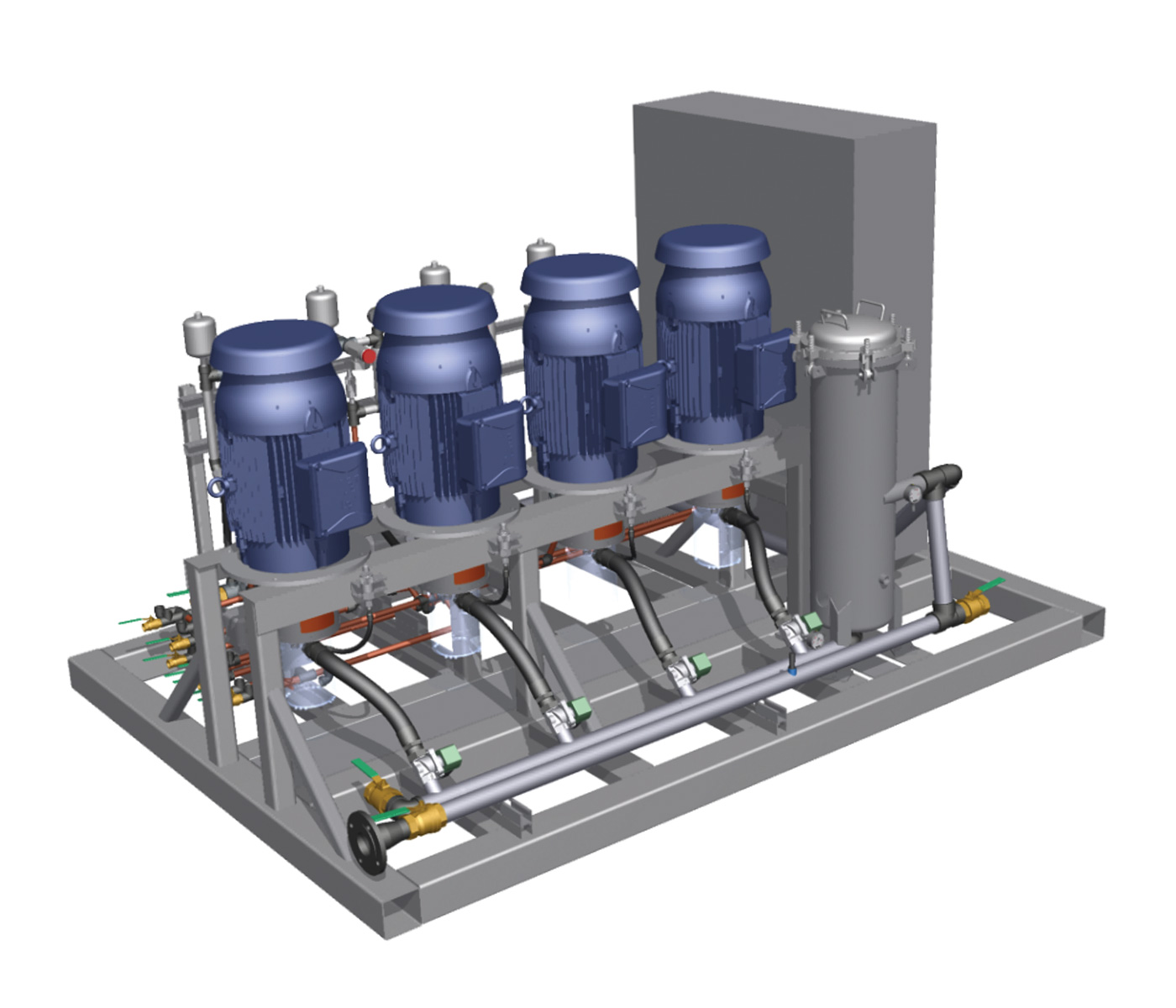

Pump Skid

Pump Skid

Stainless-steel welded frame with oversized inlet water filter. Water lubricated direct drive pumps means no oil or drive belts to change. Variable frequency drives are used to reduce flow for staging.

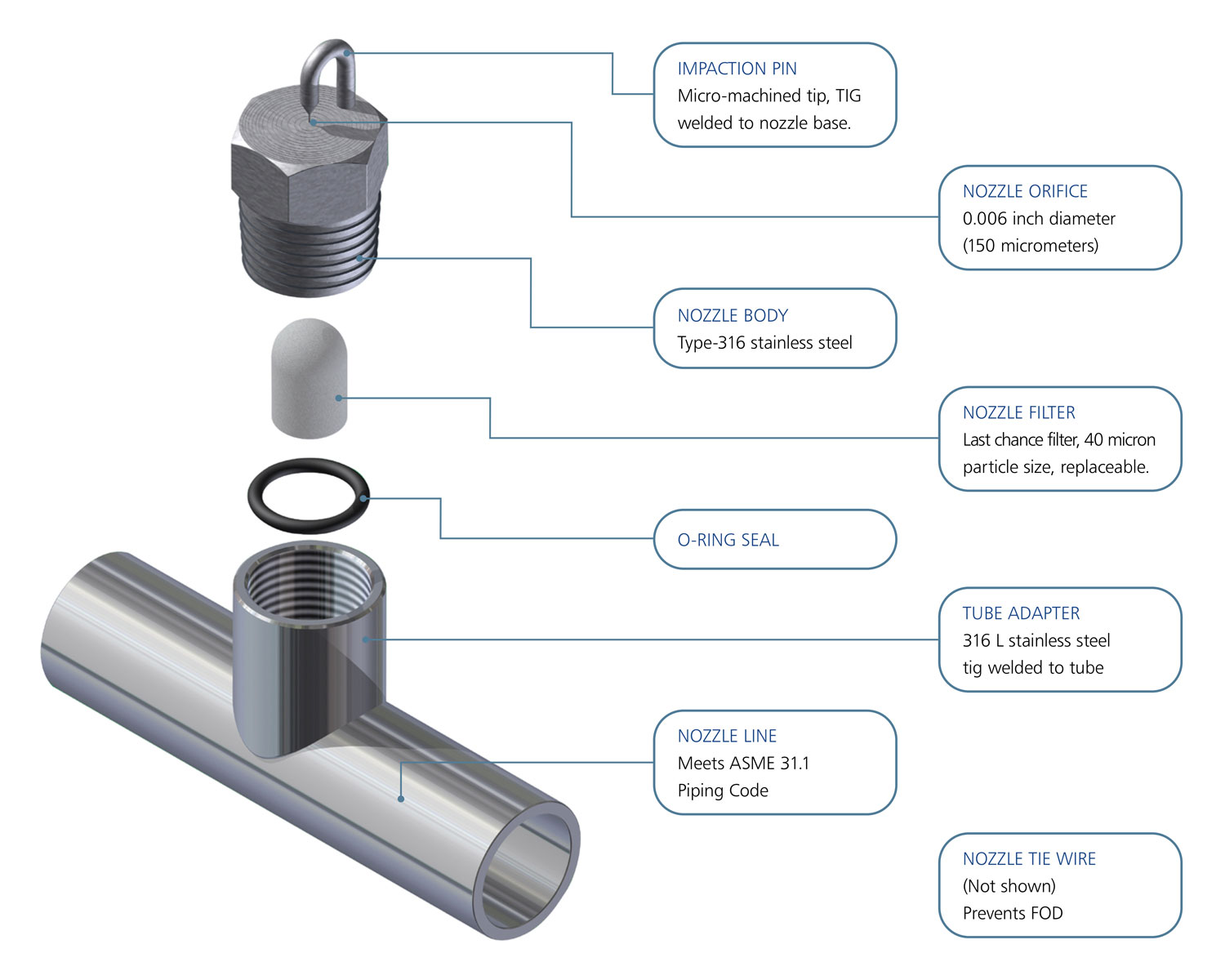

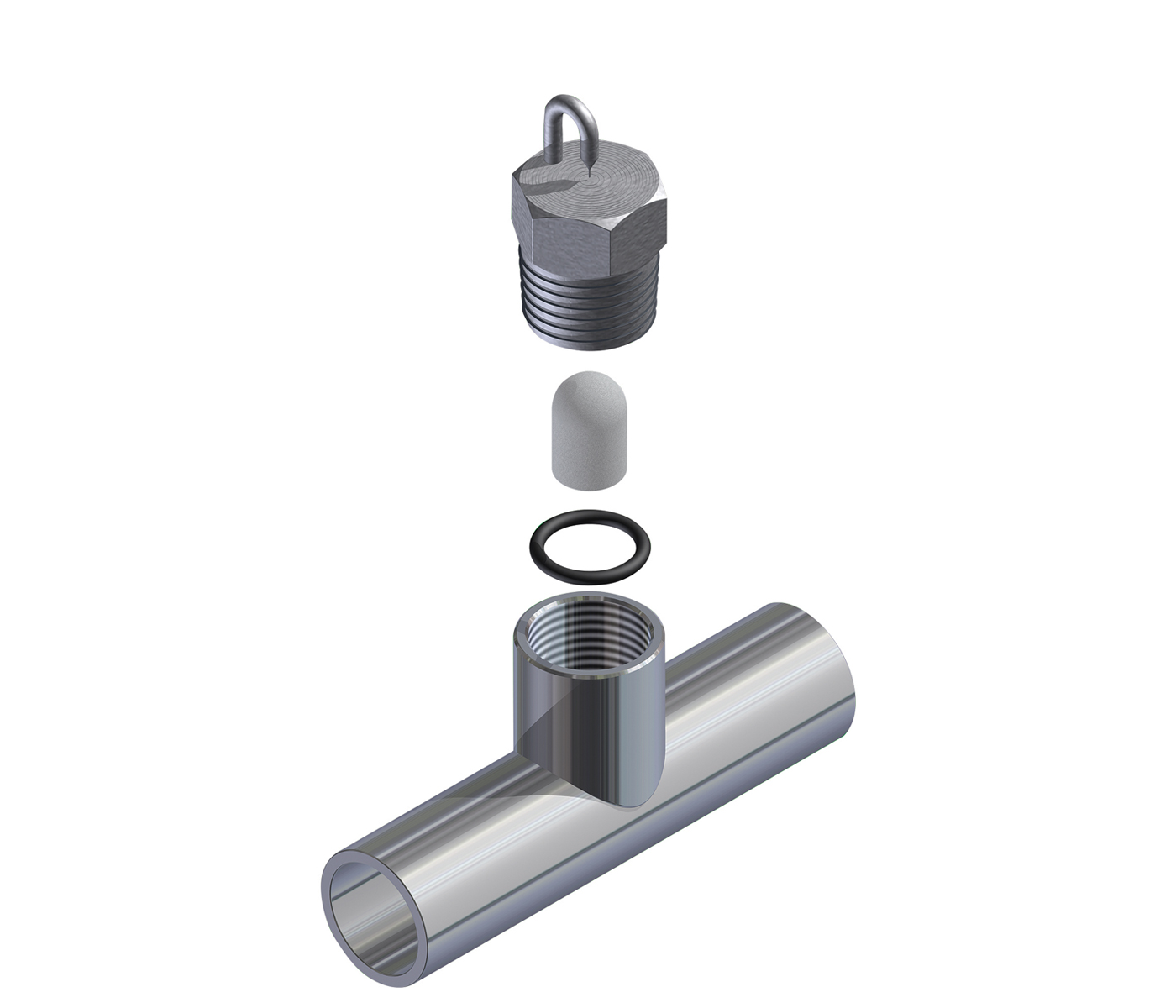

Evaporative Cooling Fog Nozzle Manifold

Evaporative Cooling Fog Nozzle Manifold

Cools to wet bulb temperature with droplets evaporating prior to entering compressor. Fog nozzles mounted on stainless steel tubing are wired for FOD avoidance. These precision nozzles are manufactured and tested in our own facility.

Wet Compression Nozzle Manifold

Wet Compression Nozzle Manifold

Fog droplets evaporate inside the compressor, giving an intercooling effect that reduces the work of compression. Water sprayed into the compressor will reduce NOx as well, but only about half as much as water sprayed into the combustors, because much of the air bypasses the combustion process.

System Overview

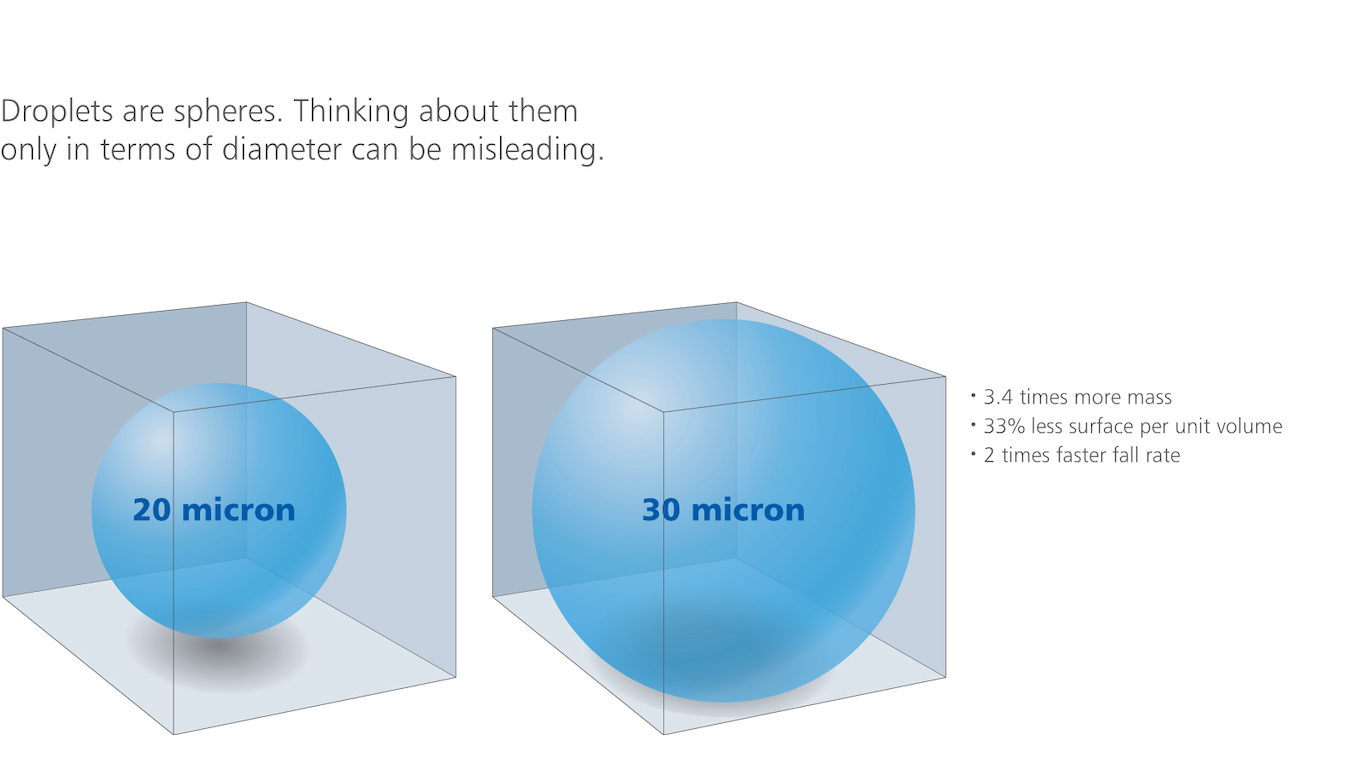

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed power recovery report for your existing gas turbines including:

- Installed MeeFog system cost.

- Predicted MW-hr gain per year.

- Fuel savings.

Featured Case Study

MeeFog Cooling System

Rapid ROI Pays for Additional Cooling Power

The Challenge

To design the most economical and effective system to increase the power output, and improve the fuel economy, for 12 ABB combustion turbines.

The Solution

MeeFog systems were custom designed and installed to allow fine control over a wider range of temperatures and humidity conditions.

Midland Cogeneration Venture needed a cost-effective way to boost output at their facility. Mee Industries installed inlet air cooling systems to augment power production on six of their ABB11NM turbines. One year after the initial installation, Midland Cogen’s Brian Vokal said the results obtained by the installation of MeeFog technology went far beyond expectations. “We are going to buy six more units using the cash generated.” Which is just what they did. As of the summer of 2011, MeeFog skids had been installed on all 12 of the plant’s gas turbines.