MeeFog vs. the Competition: A Fogging System Comparison for Data Center Cooling

Blog

TL;DR:

- Superior Efficiency: MeeFog uses finer, 27-micron droplets and higher nozzle density for complete evaporation and high cooling performance.

- Built to Last: MeeFog uses welded stainless steel manifolds for guaranteed leak-free, long-term reliability.

- Low Maintenance: MeeFog systems feature industrial-grade pumps with service intervals up to 20,000 hours, drastically reducing operating costs and failure points.

- Competitor Issues: Competitors use larger, inefficient droplets, unreliable threaded fittings, and numerous small, high-maintenance pumps requiring frequent oil changes.

Data centers require precise temperature and humidity control to maintain performance, protect equipment, and reduce energy consumption. A detailed comparison was conducted between MeeFog systems and a competitor’s fogging system for a U.S. data center project.

The results show notable differences in engineering, efficiency, and long-term dependability. These outcomes reinforce why MeeFog remains the leading choice to install fogging systems for cooling sensitive and mission-critical spaces like data centers.

Fog Nozzle Design: Precision Where It Matters

Three core design elements determine the performance of any fog spray cooling system: nozzle flow rate, nozzle coverage, and droplet size. Here is where MeeFog and the competitor stood on all three fronts.

1. Nozzle Flow Rate

- MeeFog system’s nozzle flow: 0.032 gpm

- Competitor’s nozzle flow: 0.10 gpm

Nozzle performance directly impacts the evaporation efficiency of a fog spray cooling system. MeeFog nozzles are engineered to maximize cooling with a flow rate of 0.032 gpm at 1000 psi, producing ultra-fine droplets that lead to rapid evaporation.

By comparison, the competitor uses nozzles with a 0.10 gpm flow (over three times higher), which produces larger droplets that typically fall out of the airstream before evaporating. This wastes water, reduces cooling efficiency, and can cause over-wetting of coils. Over-wetting results in water dripping to the ground instead of contributing to the cooling process.

2. Nozzle Coverage

- MeeFog: 74,418 fog nozzles

- Competitor: 23,700 fog nozzles

MeeFog’s design uses more than 74,400 nozzles, compared to just 23,700 from the competitor. Higher nozzle density provides consistent cooling across the entire heat-exchanger face, eliminating gaps where untreated air can bypass the fog.

On the other hand, insufficient nozzle count leads to uneven cooling, gaps in coverage, and increased water fallout. The competitor’s higher flow rate, combined with fewer nozzles, increases the risk of coil over-wetting and inefficient cooling.

3.Nozzle Droplet Size

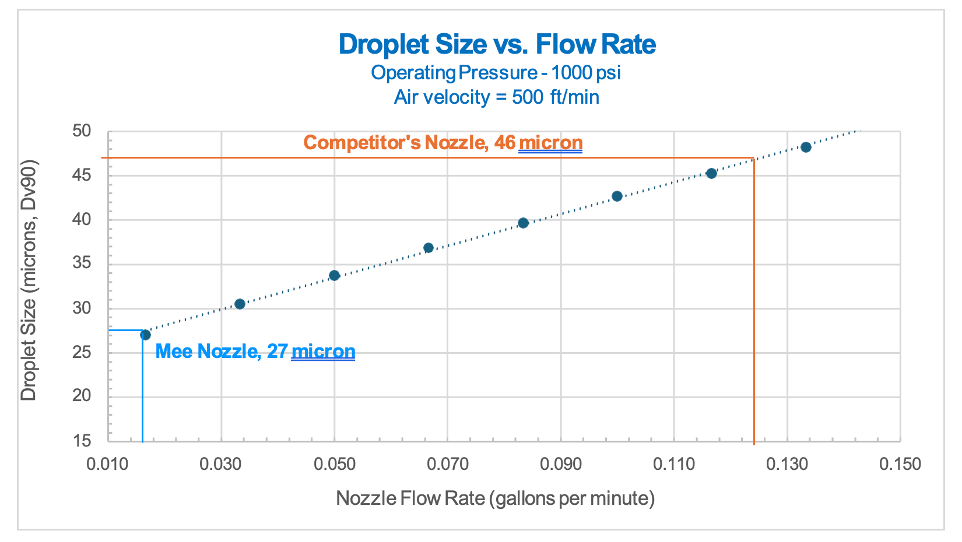

- MeeFog: 27-micron droplet (Dv90)

- Competitor: 46-micron droplet (Dv90)

Droplet size directly affects how efficiently a fogging system can operate. MeeFog produces significantly smaller droplets, with a Dv90 of 27 microns. Smaller droplets offer far greater surface area per gallon sprayed, resulting in fast evaporation and superior cooling efficiency.

Smaller fog nozzle droplets stay floating in the air longer and have more surface area relative to their volume.

The chart shows the Dv90 droplet size for nozzles with different flow rates. MeeFog’s smaller droplets not only stay suspended longer in the airstream, but they also present a much higher surface-to-volume ratio, which is key to rapid evaporation.

A 27-micron droplet provides 1.74 times more surface area per gallon than a 47-micron droplet. With evaporation occurring at the droplet’s surface, MeeFog’s fine mist delivers faster, more complete evaporation, making our fogging system one of the best for cooling sensitive areas like data centers.

Fog Manifold Design: Engineered for Leak-Free Reliability

MeeFog’s nozzle lines and adapters demonstrate engineering built for long-term performance. Proudly Made in the USA, our stainless-steel nozzle adapters are TIG-welded directly to the tubing, providing structural strength and ensuring leak-free operation.

Every line is factory-tested before shipping, reducing costly onsite troubleshooting and installation errors. Manual isolation valves for each bay simplify service and system checks.

The competitor threads the nozzle directly into the thin tube wall, creating only about 1.5 threads of engagement. This is an unreliable method and it is prone to leakage and mechanical failure.

Some competitor fogging system designs use plastic or nylon fittings, which can degrade and lead to premature failure over time. In contrast, MeeFog’s welded stainless-steel design ensures durable, long-term reliability and is Made in the USA, built to stringent quality standards.

Advanced Pump Skid Design: Built for Mission-Critical Cooling

MeeFog’s industrial-grade pump skids are UL 508A certified and built with advanced PLC controls for seamless integration with facility systems. For this project, the design included eight skids, each equipped with two high-efficiency, water-lubricated, multi-stage centrifugal pumps.

These pumps:

- Run up to 20,000 hours between servicing

- Require no oil changes

- Use direct-drive technology (no belts to adjust or replace)

The competitor proposed 100 small patio-style misting pumps, but this equipment is not intended for industrial applications. Their reciprocating piston pumps require frequent maintenance, including:

- Oil changes every 500 hours

- Seal replacements every 1,000–2,000 hours

- Higher wear due to 1725 RPM plunger-style design

MeeFog’s fogging system uses eight stainless-steel 10-micron filter vessels for the full setup. The competitor’s 100 pump units require 100 separate filters, each needing periodic maintenance. Add in 100 separate water and power connections, and the installation becomes more expensive, less efficient, and introduces hundreds of potential failure points.

MeeFog pump skid fogging system designed for mission-critical cooling, featuring stainless-steel construction and PLC integration.

Proven Engineering and Manufacturing Expertise

With more than 50 years of experience in industrial fog spray cooling system engineering, MeeFog has contributed to major advancements in atomization and cooling technology. The company has published multiple ASME peer-reviewed papers focused on efficiency, evaporation science, and droplet performance.

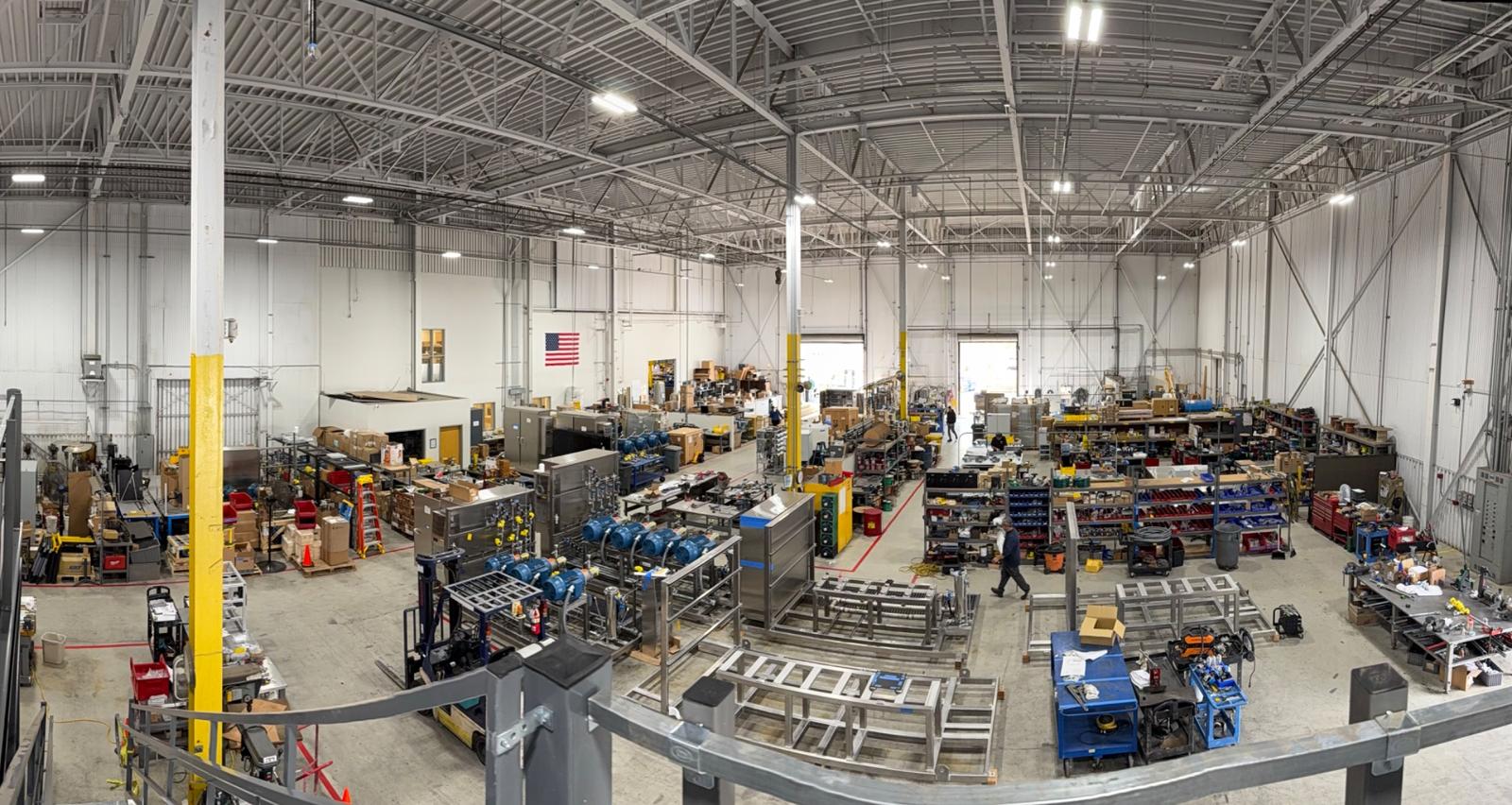

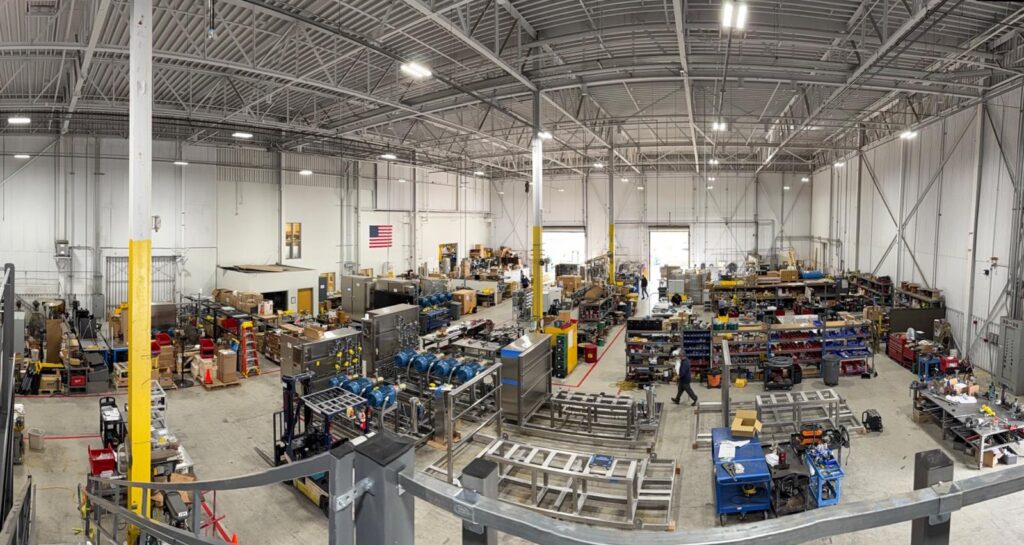

Inside MeeFog’s Industries’ U.S. manufacturing facility, where fogging systems are built to the highest standards for mission-critical cooling applications.

MeeFog’s U.S. manufacturing facility includes:

- TIG welding center

- CNC machining

- Full assembly line

- Electrical & mechanical engineering teams

- In-house PLC programming

This vertically integrated model provides full quality control, rapid customization, and precision manufacturing for mission-critical cooling solutions.

Conclusion: MeeFog Stands Apart

The comparison makes it clear. MeeFog outperforms the competition in virtually every category, from nozzle-line design and droplet size to system reliability and maintenance requirements. Our fog spray cooling systems offer better coverage, more efficient evaporation, lower operating costs, and fewer maintenance concerns.

In mission-critical environments where downtime is not an option, MeeFog provides a dependable, high-performance solution built on decades of engineering excellence.

Interested in learning more about how MeeFog can improve your facility’s cooling efficiency?

Contact our engineering team today for a custom consultation or request a quote below.