How to Increase Gas Turbine Efficiency

BlogModern Gas Turbine Efficiency vs. Older Gas Turbines

The thermal efficiency of a gas turbine represents how effectively the machine can convert heat from the combustion of fuel into mechanical work. Due to modern engineering techniques, gas turbines have evolved over the years into ever more efficient machines.

The first gas turbine to produce usable power was built by Aegidus Elling in Norway in 1903. It had a thermal efficiency of just 3% and developed 11 horsepower (0.8 MW) with a firing temperature of 752 °F (400 °C). The combustion air was water-cooled to prevent overheating of the hot-section blading. The inlet air was also water injected to improve the efficiency of the compressor.

The first gas turbine used to power an electrical generator was installed by Brown Boveri in Neuchâtel, Switzerland in 1934. It produced 4 MW of power and had a thermal efficiency of 17.4%.

The GE 7121 EA turbine, introduced in 1971, has an output of 84.9 MW at ISO conditions (59 °F or 15 °C), a pressure ratio of 12.4:1, a firing temperature of 2,019 °F (1,104 °C), and an efficiency of 33.4%.

The GE 7F.02 gas turbine that entered service in 1990 has a pressure ratio of 14.8:1 and a firing temperature of 2350°F (1,288 °C) and is 36.9% efficient.

A larger turbine, such as the GE 9HA.02 (launched in 2018), has an efficiency of 42.7% and produces 385.5 MW at ISO conditions. It has a pressure ratio of 23:1 and a firing temperature of 2,750 °F (1,510 °C).

The LM9000, co-developed by Baker Hughes and GE and first tested in 2020, is the most efficient gas turbine currently available on the market. It has a pressure ratio of 33:1, simple cycle efficiency as high as 46% and an output of 73.5 MW at ISO.

The LM9000 has a free power turbine, meaning the turbine that drives the load is on a separate shaft from the core turbine. This allows it to drive a load at different speeds without the use of a gearbox and while the core turbine runs at its optimum speed.

Older turbines are less efficient due to lower pressure ratios, reduced firing temperatures, and less efficient compressors and expansion turbines. The lower pressure ratio means the air is not heated as much during compression, so more fuel needs to be added to reach the firing temperature. Lower compressor efficiency means more of the power produced by the expansion turbine is consumed by the compressor.

A lower firing temperature was necessary because older metallurgy couldn’t withstand high temperatures, and hot-section cooling was not as effective. Higher firing temperature means more energy is available for the expansion turbine to convert into useful mechanical work, so the efficiency is greater.

Upgrading Turbine Efficiency

Gas turbine OEMs offer upgrades for both gas turbine compressors and hot sections.

These upgrades include upgrades to advanced compressors, combustors, new hot gas path and turbine rotor components, along with advanced accessories and software solutions to boost output and efficiency.

Efficiency can be increased by 2% to 2.5% but the cost can be several million dollars.

Installing Inlet Air Cooling to Increase Efficiency

Cooling the gas turbine inlet air can increase efficiency by up to 3%.

The compressor of a gas turbine moves a nearly constant volume of air, and Inlet air cooling makes the air denser, so cooling the air increases the mass flow through the turbine, which in turn increases the output and efficiency even when firing temperature is unchanged. Cooling also reduces compressor work. This means the compressor consumes less of the power produced by the expansion turbine, so more power is available at the output shaft.

However, the efficiency improvement from inlet air cooling only occurs when the turbine makes more power. Cooling a turbine operating below base load does not provide an efficiency increase significant enough to be economically viable. This is because the loss in efficiency due to operating at less than base load—lower firing temperature—is greater than the gain in efficiency due to inlet cooling. Inlet air cooling isn’t helpful if the goal is to increase efficiency, without also generating more power.

For example, if one needs to operate a gas turbine at 70% load, it could instead be operated at 60% load with inlet air cooling in operation to bring the load back up to 70%, but the turbine will not be more efficient running at 60% load with inlet air cooling, than it was at 70% load without inlet air cooling.

Retrofitting Inlet Air Cooling to an Existing Gas Turbine

Gas turbine inlet air can be cooled with a media-type evaporative cooler, which consists of a wetted media through which air flows. Water evaporates from the media, which cools the air.

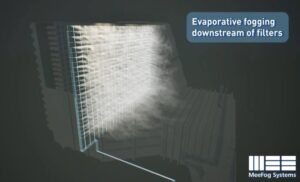

Fog systems can also be used to cool inlet air. They work by spraying a fog of atomized water into the inlet airflow, usually just downstream of the inlet air filters. The fog droplets evaporate quickly and cool the air. Demineralized water must be used to avoid fouling the compressor with mineral deposits.

Evaporative cooling is most effective in hot and dry environments, but it is still economically viable even in humid, tropical climates. For example, many successful fog system installations exist in Southeast Asia, along the Gulf Coast of the United States and Mexico, and in continental climates where summers are extremely hot and humid.

The power boost varies for different gas turbines; a reduction of 20 °F (11 °C) can increase output from 7% to 12% for an industrial gas turbine, and by as much as 32% for an aeroderivative gas turbine.

Fogging is less expensive to retrofit to a gas turbine than a media-type evaporative coolers because fogging requires almost no modifications to the inlet filter house and duct.

Inlet air can also be cooled with a chiller. A chiller can provide more cooling than evaporative systems, but they are expensive to install, take a lot of real estate, require a lot of maintenance, and have a high parasitic power load. In recent years some operators have opted to replace old chillers with fog systems.

Installing Wet Compression to Increase Efficiency

Wet compression consists of spraying liquid water droplets directly into the compressor of a gas turbine. The droplets evaporate inside the compressor, which provides an inter-cooling effect.

The inter-cooling reduces the work of compression, making more power available at the output shaft, and the compressor discharge temperature is reduced, which allows more fuel to be burned to reach the firing temperature.

The increased fuel flow contributes to the mass flow through the turbine, resulting in increased power output. The mass of the wet compression spray also increases mass flow and power output.

A wet compression spray at a rate of 2% of the inlet air mass flow can produce a power boost of 16% to 20%, depending on the gas turbine, and can increase efficiency by as much as 10%.

Like inlet air cooling, wet compression only increases efficiency if the gas turbine is allowed to produce more power.

Inlet Conditioning vs. Upgrading the GT

Both evaporative fogging and wet compression can make a gas turbine considerably more efficient if one is willing to accept the additional power produced.

They are considerably less expensive than OEM upgrades and can increase the efficiency of both non-upgraded and upgraded gas turbines.

Conclusion

Inlet air evaporative fogging and wet compression can produce a significant power boost and an increase in thermal efficiency, at a price that is very competitive compared to other options.

Your MeeFog representative can assist with modeling the effects of both fog evaporative cooling and wet compression on the output and efficiency of a particular gas turbine. We use gas turbine modeling software and climate data to produce accurate estimates of the annual power boost available and the improvement in efficiency. The analyses include the water and power used by the fog system in a typical year, allowing operators to see the full impact of fogging on their operation.