Gas Turbine Inlet Air Fogging on Two SW 501FD2 GTs

Gas Turbine Wet Compression

A Southwestern US Power Station installed MeeFog Systems on two SW 501FD2 gas turbines. Each system provides wet compression (2% of air mass flow) and produces a 22 MW power boost. The GT controls were modified so when wet compression is in operation the GT switches to a “wet-control curve.” This ensures a constant firing temperature is maintained, so the maximum wet compression power boost is obtained, and CO emissions stay within permitted limits.

Project Conditions:

- Elevation: 2842 feet above sea level

- Model: SW 501FD2 Gas Turbine

- Max Power Boost: 22 MW

- Mee’s Scope of Work: supply of fog pump skid, nozzle manifolds, and supervision of installation and

commissioning.

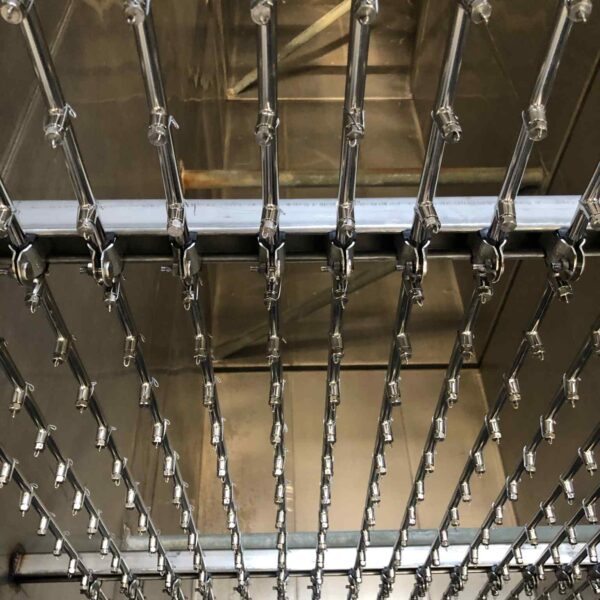

Fog Skid Design:

- Fogging Stages: 16

- Operating Pressure: 2,000 psi

- Fog Droplet Size: 8 microns SMD

- MeeFog™ Nozzle Count: 3,072

- Nozzle Flow Rate: 0.045 gpm per nozzle

- Max. Water Flow: 138 gpm

- Max. Power Requirement: 240 HP

Learn More About Meefog Systems

Read about the benefits of Meefog’s Fog Cooling System from previous successful installations:

Other Related Blog Articles

Gas Turbine Wet Compression

Wet Compression Boosts Power Output by 28 MW

Project Profile: MeeFog’s wet compression systems enhances power output by 28 MW for two GE 7F.03 turbines,......

Gas Turbine Wet Compression

Maximizing Power Output with MeeFog Systems at Tuxpan Power Plant, Mexico

Case Study: How the Tuxpan Power Plant in Mexico leveraged MeeFog Wet Compression to enhance gas turbine......