Humidification for Cleanrooms

Humidity for Manufacturing & Research Cleanrooms

Microchip & Semiconductor

To preserve the integrity of the clean room envelope, positive pressure has to be maintained in the room at all times. To accomplish this, large amounts of outside air are required to off set the exhaust and room leakage. The large air flows must have tight temperature and humidity control, and doing so in a budget friendly way is important.

Benefits:

• Reduces electrostatic shock.

• Low energy consumption.

• Precise humidity level control.

• Ultra-fine droplets evaporate – no wetting.

Aerospace & Auto Paint Booths

MeeFog is able to provide humidity for large airflows with a single MeeFog system. Lower energy costs than a steam humidifier and low maintenance means the system can pay for itself in a matter of years. Proper humidity control can solve issues with fluctuations in moisture which may cause costly defects. Many spraying and bonding processes will benefit as dry air can cause premature drying.

Benefits:

• Maintain moisture content while curing.

• Reduce dust and static control problems.

• Enable product repeatability.

• Lessen down-time.

Pharmaceutical

Manufacturing pharmaceuticals requires a controlled environment. In cleanrooms, it is especially important to maintain a perfect relative humidity. The MeeFog system is integrated into the building management system and controls the building humidity levels perfectly. Return on investment in two years is common due to low maintenance and energy costs.

Features:

• Evenly distributed humidification.

• Increased reliability.

• Reduced energy costs.

• Improved product quality.

• Does not require compressed air or steam.

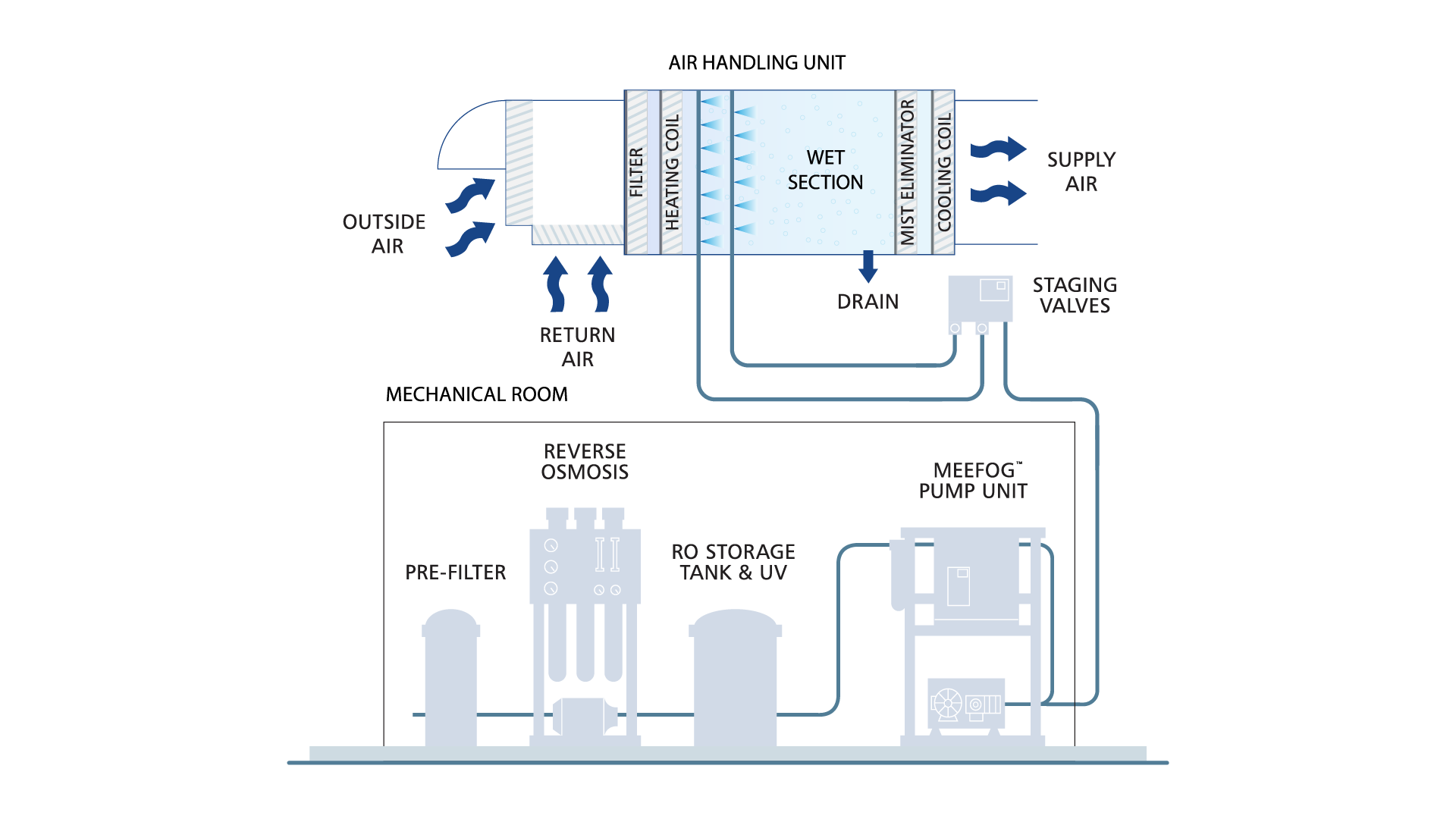

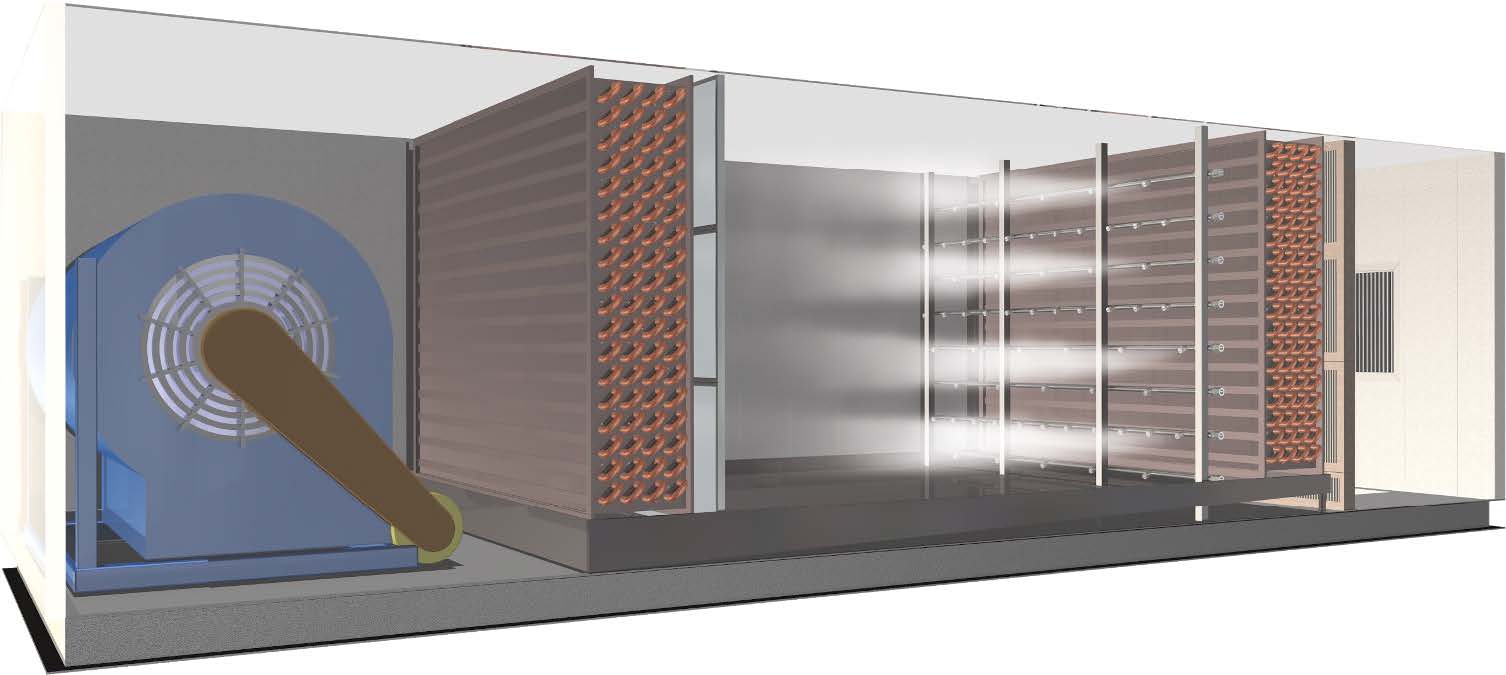

MeeFog HVAC Installation Diagram

Click the different areas of the diagram below to learn more information about our system.

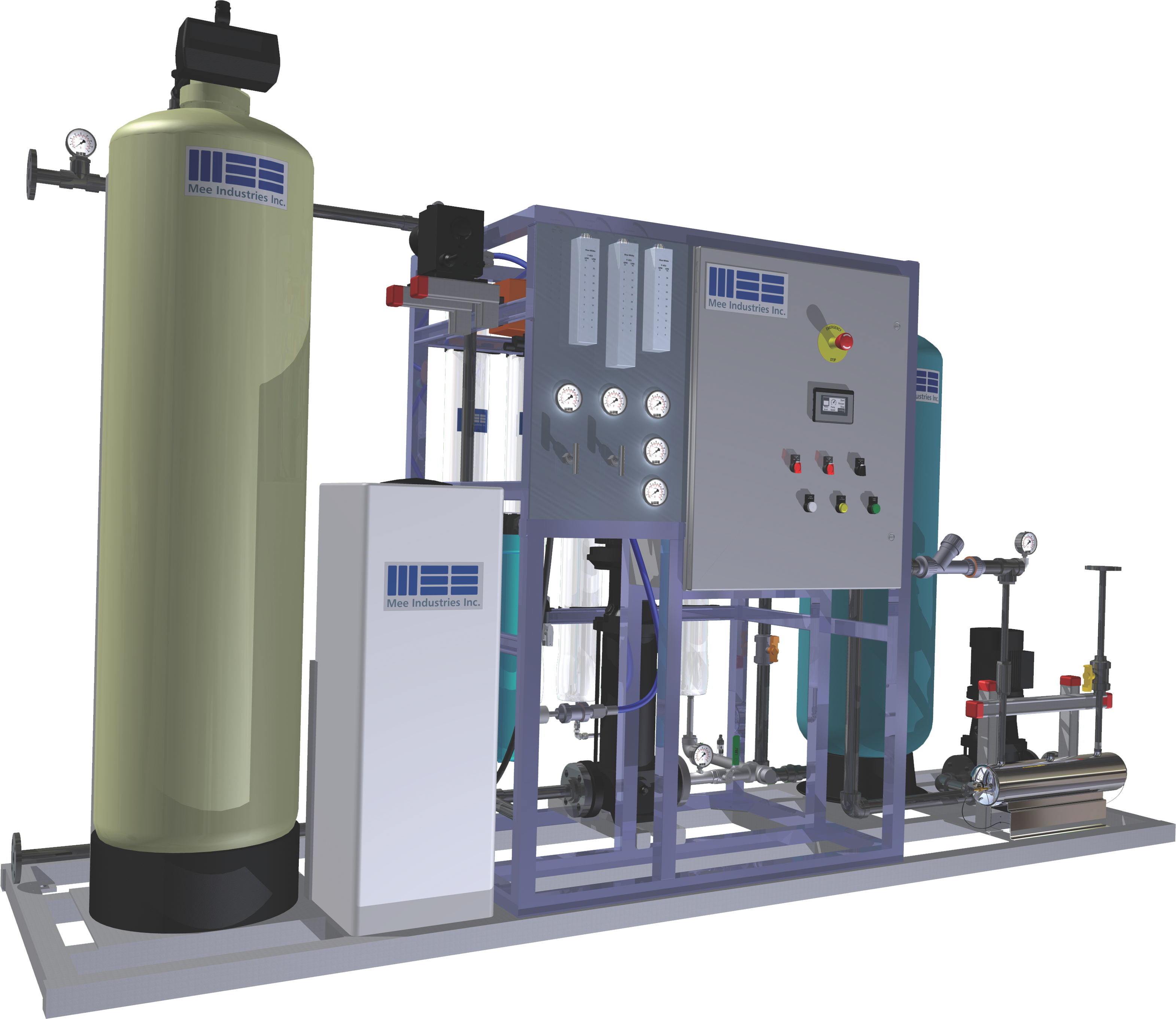

Reverse Osmosis Water Purification

Reverse Osmosis Water Purification

City water is treated using the Reverse Osmosis water treatment rack. This purifies the water, removing minerals, particulate, and microorganisms. Systems include automated membrane flushing, pre-treatment filtration, and UV Re-Circulation.

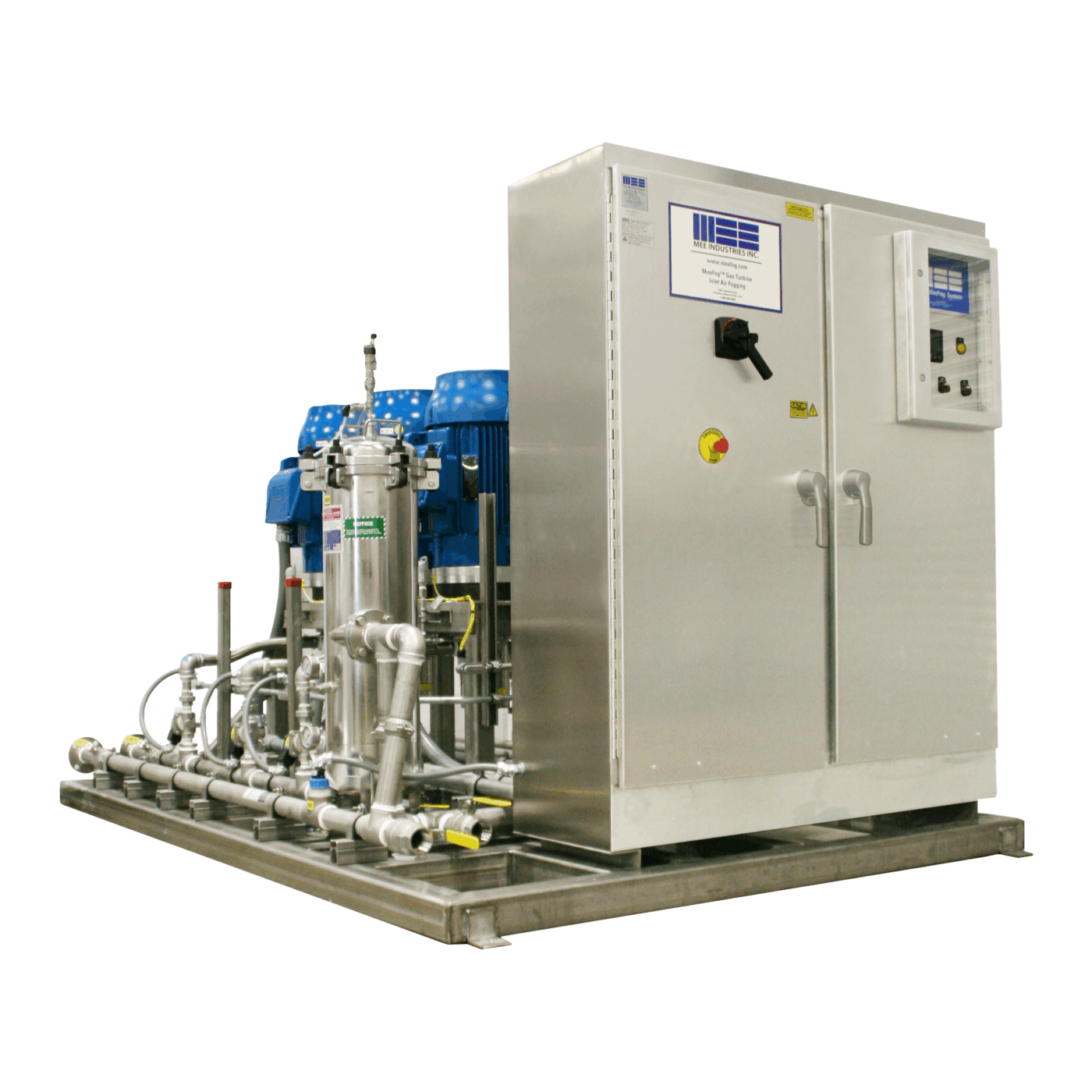

MeeFog Pump

MeeFog Pump

The high-pressure pump maintains 1000 psi water pressure in order to atomize the water into tiny droplets that can evaporate into the air stream. The pump rack has a VFD with panel-mounted controller that maintains pressure when staging valves open and close.

Staging Valves

Staging Valves

The valve panel allows precise control over how much humidification is injected into the air stream based on a signal from the BMS. It is possible to control the humidification level in the space to plus or minus 1% RH.

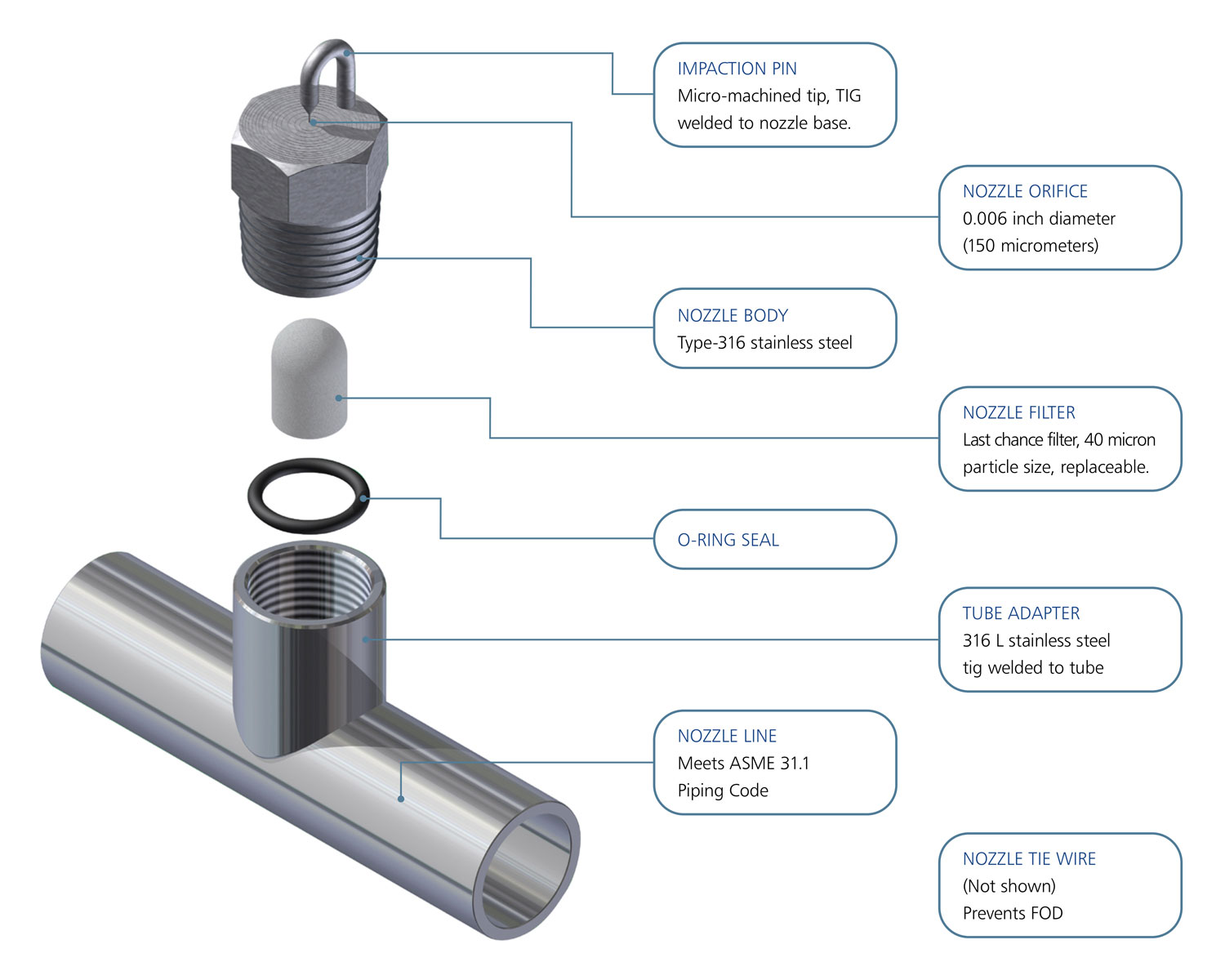

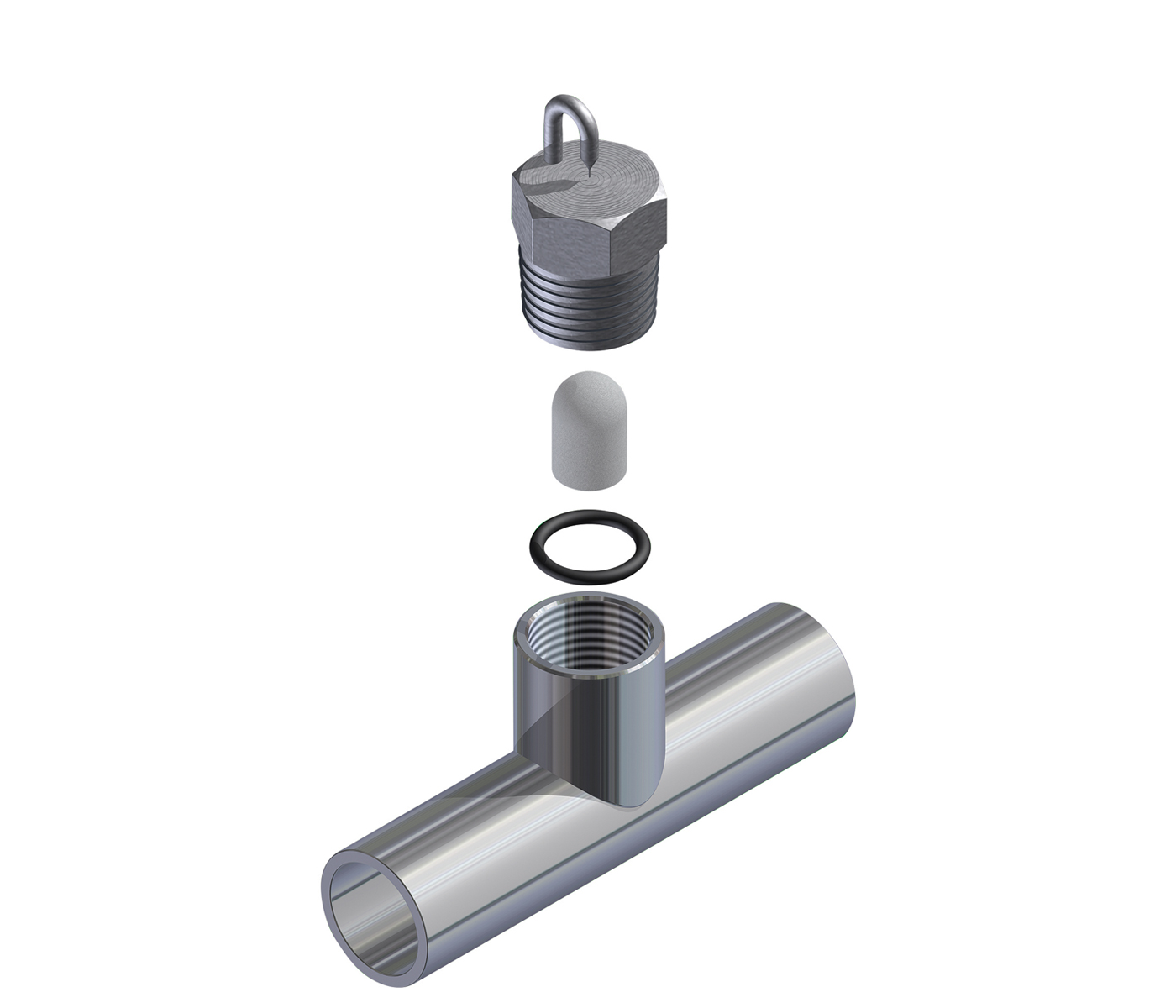

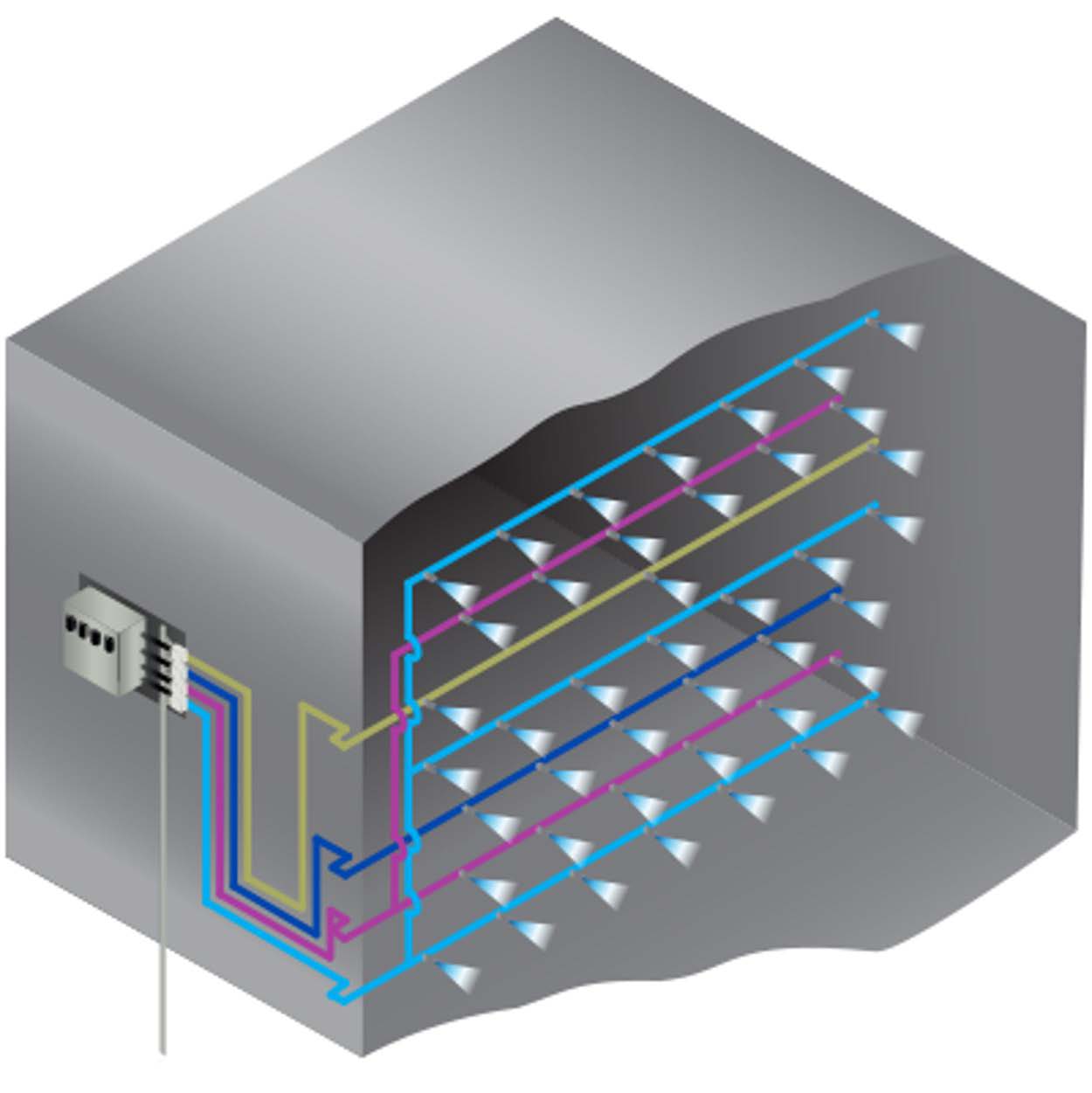

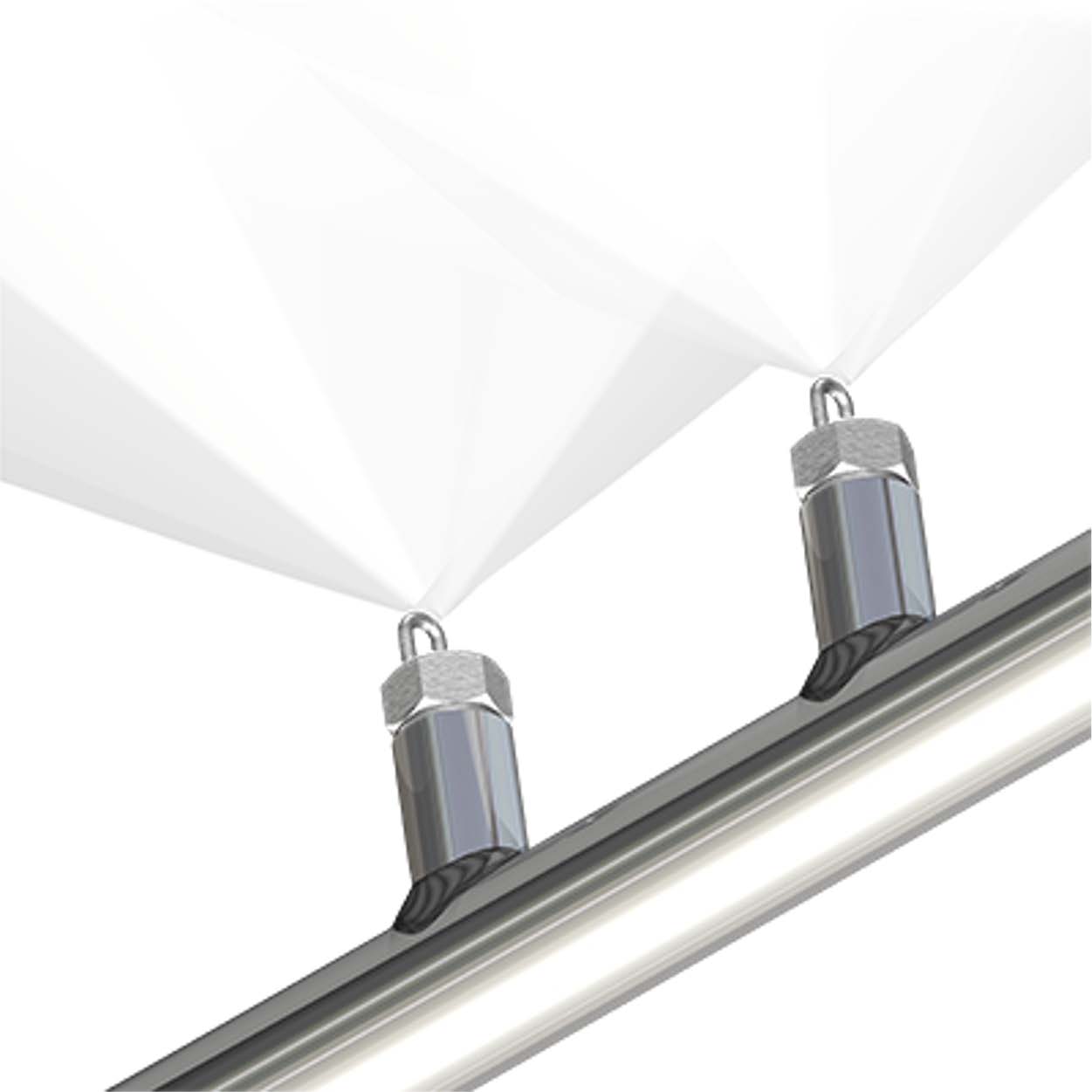

Nozzle Manifolds

Nozzle Manifolds

Fog nozzles are mounted on stainless steel tubing inside the air handler. These nozzles produce droplets in the 10-micron range. These precision nozzles are manufactured and tested in Mee Industries' own facility.

Mist Eliminator

Mist Eliminator

The mist eliminator removes water droplets larger than 5 microns. The filter pads can come off their stainless steel frames and can be washed or replaced easily.

System Overview

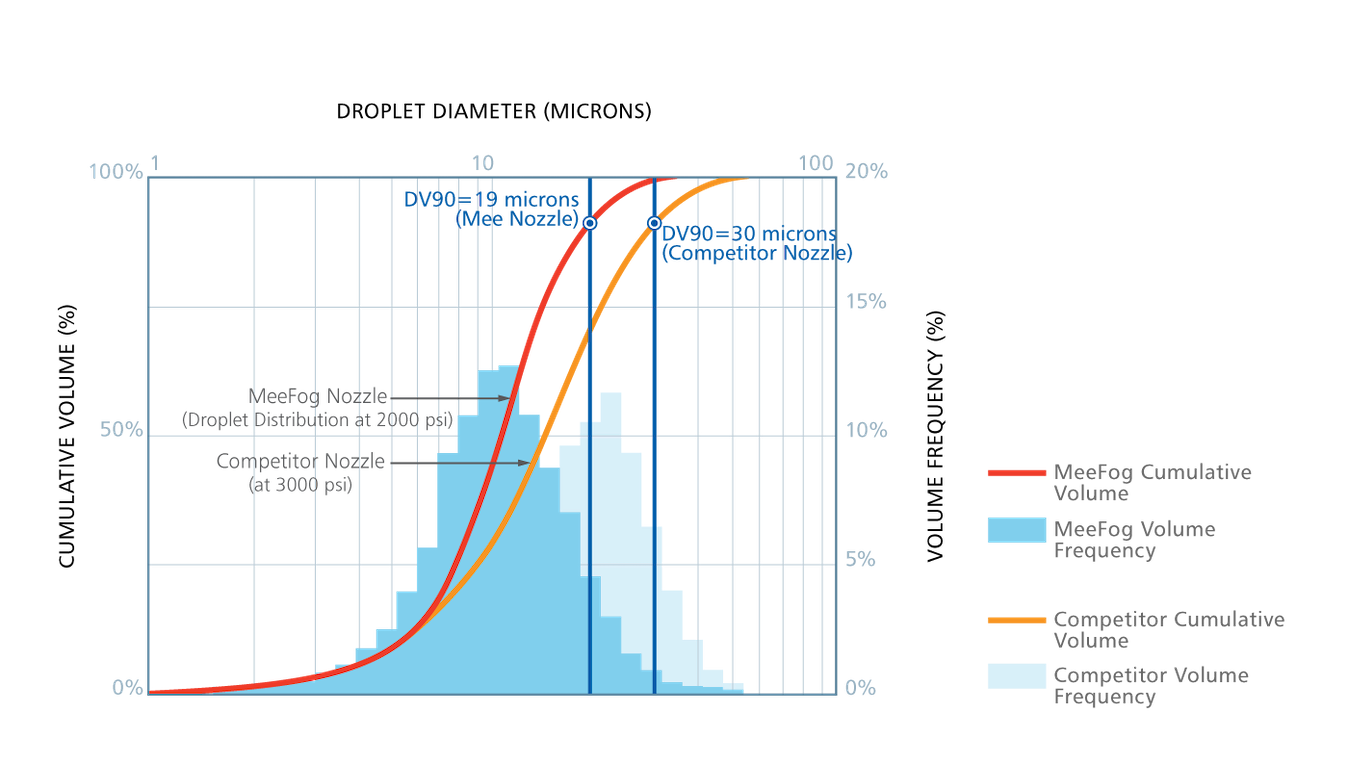

Nozzle Comparison

At an operating pressure of 2000 psi, the resulting average droplet size is roughly one tenth the diameter of a single strand of human hair.

MeeFog System Benefits

- Minimizes the risk of airborne infections.

- Decreases the occurrence of respiratory issues in newborns.

- Low energy consumption.

- Precise humidity level control.

- Elevates patient and staff overall comfort and virus protection.

- Lowers employee absence rate.

- Reduces premature drying and formation of scabs from coagulated blood.

- Prevention of electrostatic damage to medical equipment.

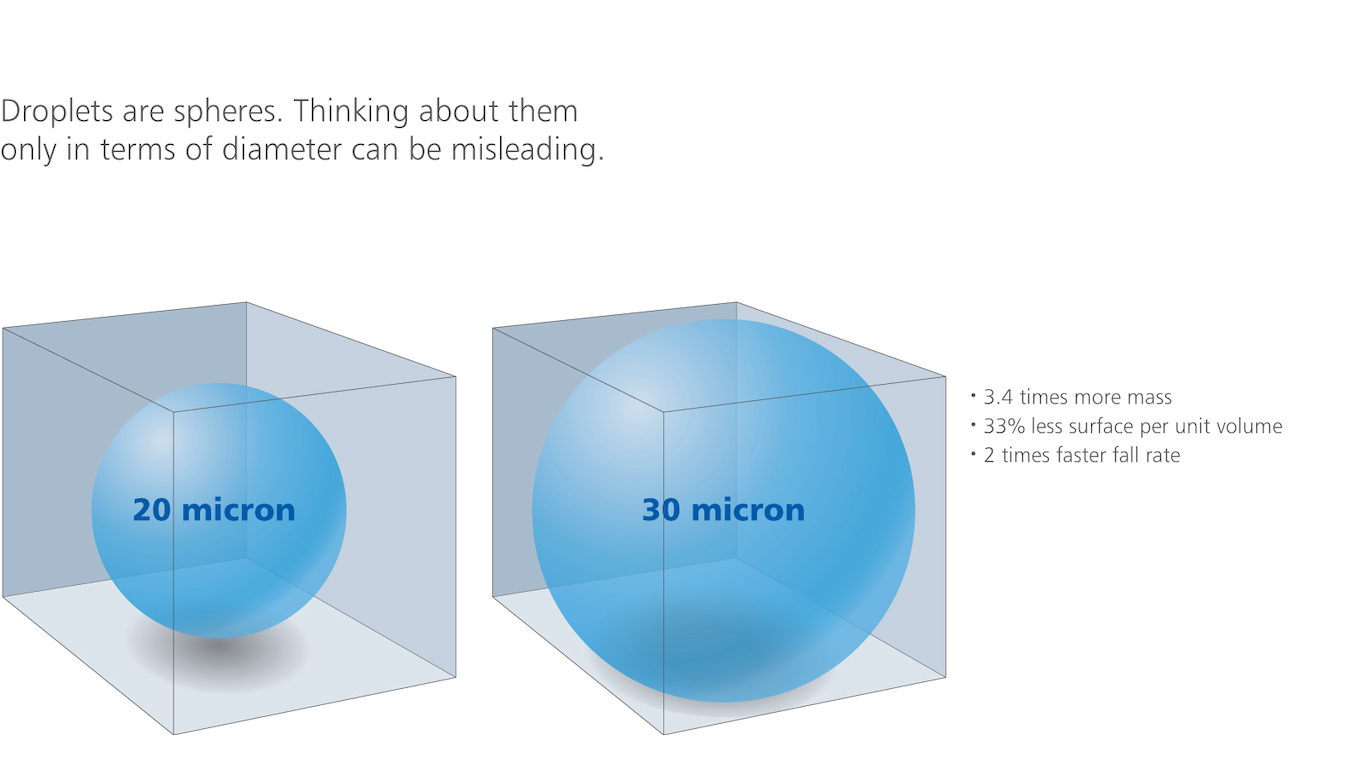

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed payback analysis report for your Hospital or Medical Center including:

- Installed MeeFog system cost.

- Predicted process gains per year.

Featured Case Study

Army Research Laboratory Uses CHP and MeeFog Humidification to Cut Energy and O&M Costs

The Challenge:

The Army Research Laboratory in Adelphi, Maryland had been using a boiler to provide hot water as well as steam humidification to two clean rooms. It recently installed a combined heat and power system in its central utility plant, but the hot water generated was not hot enough to provide needed humidification.

The Solution:

A Meefog system was installed to provide humidification to both clean rooms, at a much lower cost and with less maintenance than the boiler.

The Army Research Laboratory in Adelphi, Maryland had been using a boiler to provide hot water as well as steam humidification to two clean rooms. A MeeFog system was installed to provide humidification to both clean rooms, at a much lower cost and with less maintenance than the boiler.