Premier Cancer Center Saves $35,000 a Year with a MeeFog System

Hospital & Healthcare

Why Fog is Better

One of the world’s leading cancer research and treatment facilities needed to maintain a consistent environment in its vivariums. This includes being able to maintain the humidity levels on even the coldest winter days while using 100% outside air.

A 3hp MeeFog humidification system with a variable speed pump and four levels of fogging gave the cancer center the control it needed, while saving tens of thousands of dollars annually in electricity costs.

Major NYC Cancer Research and Treatment Center

The world’s oldest and one of its premier cancer research centers, it operates a 470 bed hospital, a 23 story research building and other research and treatment facilities throughout the tri-state area around New York City.

Installation Challenges/Specifications:

The cancer center has a 14,000 square foot vivarium, an area outfitted for keeping of animals, occupying a full floor in one of its buildings. The vivarium had a compressed air humidification system but it wasn’t providing the necessary control over the air quality.

“In a vivarium you have to have tight control of 30-60% humidity and 72°F (+/-2°) in the space at all times while using 100% outside air,” says the center’s General Manager – Plant Operations, Energy and Engineering. “Trying to control humidity on a 20 degree day in the middle of winter was quite hard at times with the old system.”

The Installation:

To bring the humidity under control, the General Manager decided to try a MeeFog humidification system. For the vivarium, the task was to create a system that could maintain 50% RH even on the coldest days, with the two air handlers each pulling in 20,000 CFM of subfreezing air. This would require the addition of 1528 lbs. of water per hour, or 3.06 gpm. Mee designed a system that used a single 3 hp, 950 rpm positive displacement pump with a variable speed drive to provide 4 gpm of 1500 psi water to the fogging nozzle arrays. Eight solenoid valves would control the water flow to the arrays, giving four stages of humidification for each of the air handlers.

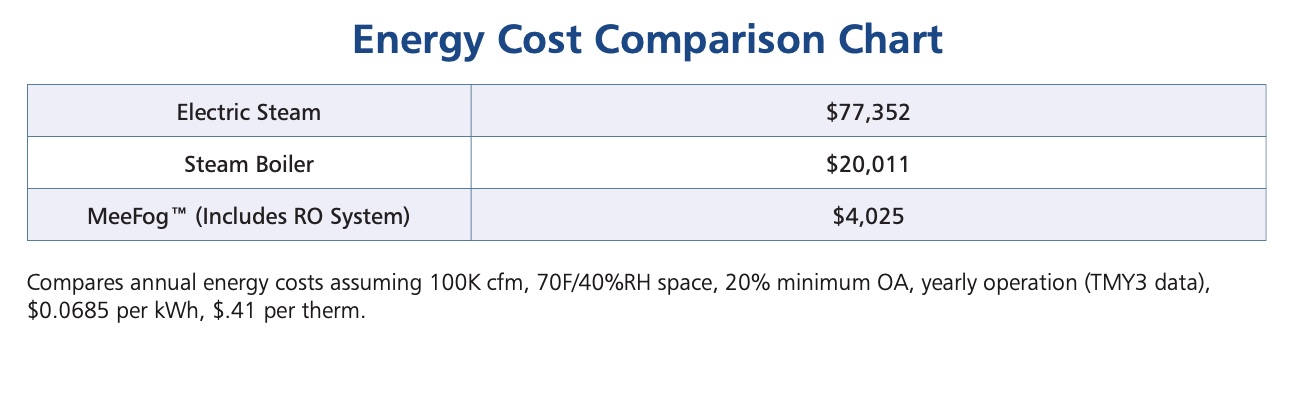

An analysis of the ambient temperatures showed that the fogging system would need to operate at the equivalent of full load for the equivalent of 2,334 hours per year. From there, calculations were made comparing the cost of operating the 3.0 kW MeeFog system with the 40.7 kW compressed air atomizing system, including make up energy cost to account for the cooling effect of the evaporating fog. The Meefog system would cost about $65,000 but would save $35,000 per year in electricity. (See Chart 2.)

“The numbers came back very attractive and we purchased it,” he says. “We also received a $16,000 energy savings rebate from Con Edison so the payback worked out to just under two years.”

Mee Industries provided a turnkey system including the pump, controllers, waterlines, nozzles, fog manifolds, solenoid valves and droplet filters. Startup and training were provided by Mee, but his crew did the installation. He says it would have taken two technicians about a week to install the equipment and do the plumbing and electrical, but due to other commitments they weren’t able to work on it full time. The fogging manifolds are installed inside the air handlers between the preheat coil and the cooling coil. The MeeFog system ties into the facility’s Siemens building management system.

Cost/Benefit Analysis:

The system went live in time for the Winter 2011/2012 season, and the research center is continuing to run it in the shoulder seasons as well. Besides the energy savings, he says the MeeFog system requires much less maintenance than the earlier system, just changing the pump oil monthly and the nozzles once a year. But most importantly, it does a better job.

“The MeeFog system held humidity levels much tighter than we had before with the old system,” says the General Manager. “It was the first winter where I had no complaints about the vivarium humidification levels.”

Based on his experience with the vivarium, he is proposing that MeeFog systems become the standard for new humidification systems throughout the institution.

Learn More

Discover more successful Mee Industries building humidification systems installation projects and case studies