Is Wet Compression Safe for Gas Turbines? Proven Success with MeeFog Systems

Blog

Is Wet Compression Safe for Gas Turbines? Proven Success with MeeFog Systems

TL;DR:

- Erosion Risk Eliminated: The fear of compressor blade erosion is a myth based on outdated, poorly designed systems that produced large water droplets.

- Safety Proven: Modern MeeFog Systems have over 1,000 installations and decades of zero-erosion operation, confirming wet compression is safe when engineered correctly.

- Key Technology: Safety is achieved through precision atomization, generating ultra-fine droplets 20 microns that evaporate completely before reaching the compressor blades, preventing liquid impaction.

- Performance Gain: Wet compression uses this evaporative intercooling to increase air density and lower compressor work, resulting in a 5% to 10% increase in power output.

- Real-World Success: Case studies show +7 MW to +12 MW power boosts and excellent blade condition even after over 20 years of continuous use.

Decades ago, some operators questioned whether wet compression could cause compressor blade erosion in gas turbines. But after more than twenty years of real-world data and field-tested reliability, the results speak for themselves:

When designed and operated correctly, with careful attention to droplet size, water purity, and injection rate, wet compression has proven to be one of the safest and most effective ways to boost gas turbine output and efficiency.

With over 1,000 installations across 30+ countries, MeeFog systems have become the trusted standard for safe, high-performance wet compression. Backed by decades of research and continuous innovation in fogging system design, MeeFog delivers measurable results without compromising turbine health.

How Wet Compression Works to Improve Turbine Output

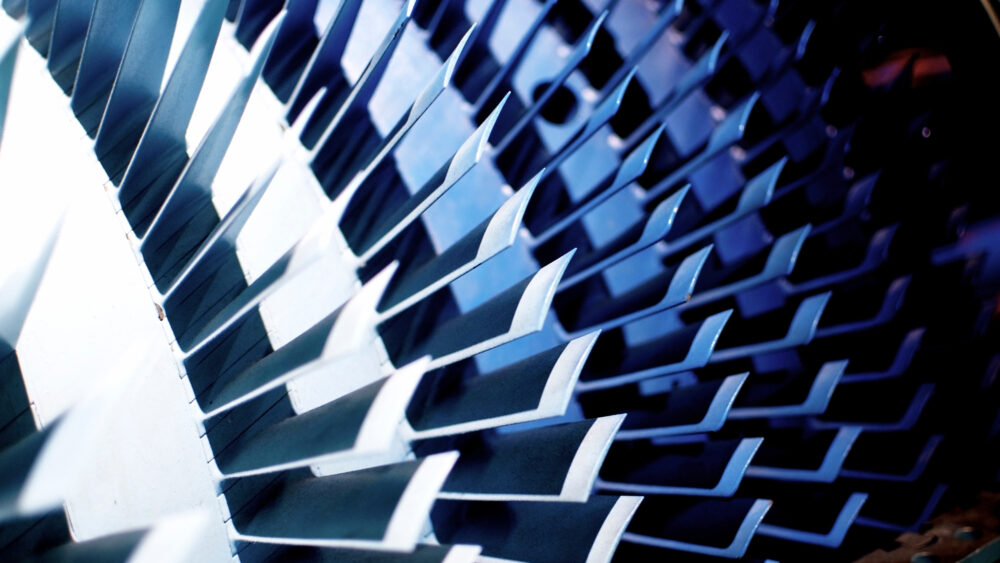

Wet compression involves the injection of atomized water droplets directly into the compressor inlet of a gas turbine. These fine droplets evaporate within the compressor, creating an internal cooling effect, typically called evaporative intercooling. This simple process lowers compressor work, increases air density, and boosts turbine output.

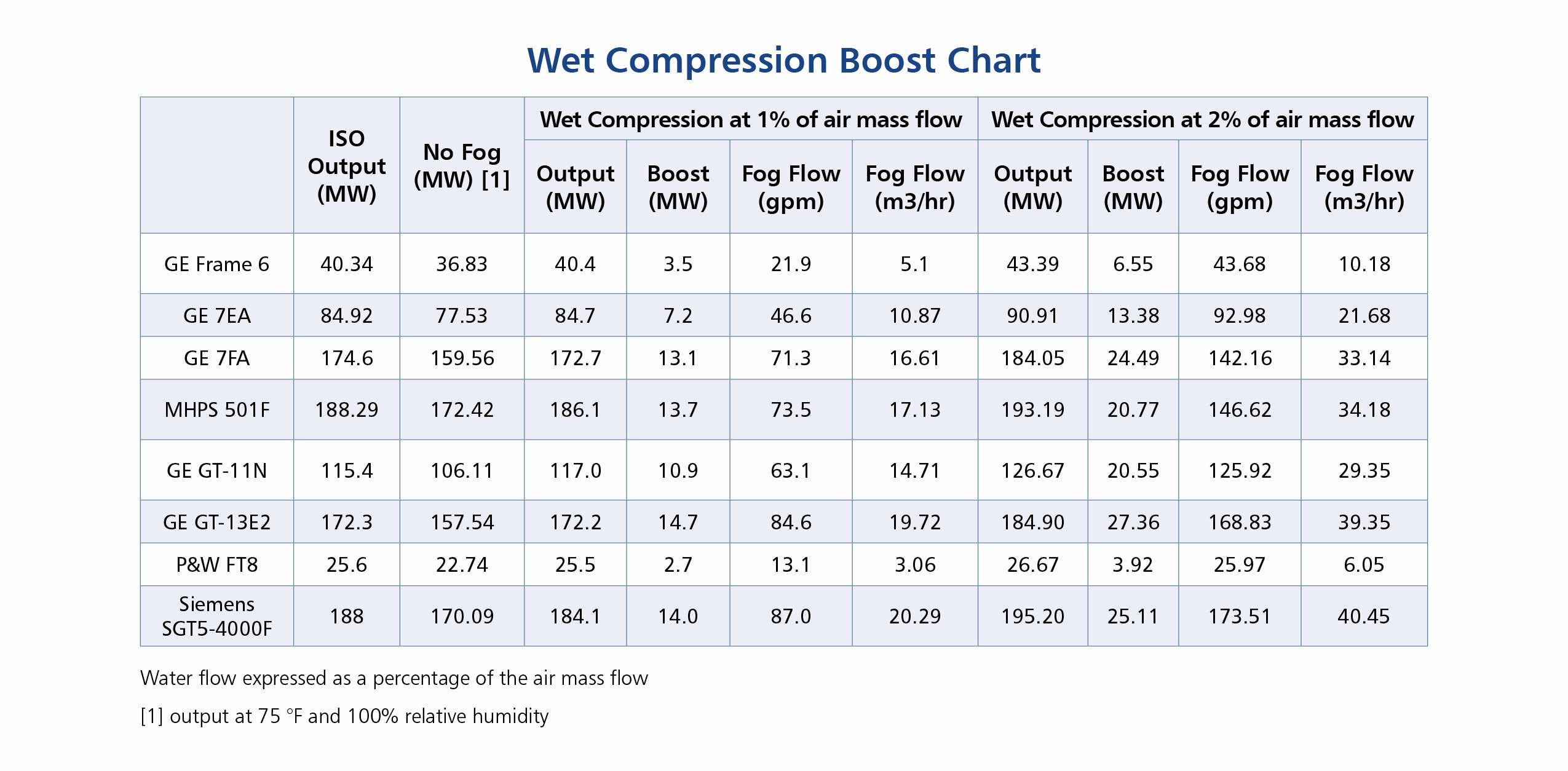

In practical terms, operators usually see a 5% to 10% increase in power for every 1% of water injected relative to the inlet air mass flow. Some plants inject water equal to about 2.5% of the incoming air mass, achieving substantial performance gains.

This approach is similar in concept to a fog spray cooling system, where precision atomization and rapid evaporation create measurable cooling effects. The same principle applies here: smaller droplets evaporate faster, cooling the compressor efficiently and improving overall turbine performance.

Check this article to learn more about how to increase gas turbine efficiency through wet compression and other techniques.

Blade Erosion Myths and the Truth About Droplet Size

Many plant managers still worry about blade erosion from water injection systems. This concern is not unfounded because older wet compression systems often used outdated nozzles that produced oversized droplets. These large droplets caused impact erosion, leading to microfractures and pitting on turbine blades.

However, the issue was never the concept of wet compression itself. It was a poor fogging system design. Large droplets typically did not evaporate fully and struck compressor blades at high speed, gradually wearing away the metal surface.

Modern systems, like MeeFog’s fogging system for cooling, eliminate this risk. By producing ultra-fine droplets that evaporate almost instantly, MeeFog prevents liquid impaction and maintains compressor integrity.

Why Droplet Size Matters in Wet Compression

Droplet size is the single most important factor in avoiding erosion. MeeFog systems generate droplets averaging 20 microns in diameter, which are small enough to stay suspended in the airstream long enough to evaporate completely before reaching the compressor blades.

This precision atomization is achieved through high-pressure stainless-steel nozzles designed for consistent droplet size and distribution. The result is complete evaporation and uniform intercooling, with no risk of blade impact or material loss.

Older wet compression setups used low-pressure nozzles with inconsistent spray patterns. These systems created uneven cooling zones, poor evaporation, and actual erosion over time. In contrast, the MeeFog fog spray cooling system uses finely tuned nozzles and demineralized water to protect both the compressor and turbine from wear, corrosion, or scaling.

If your facility still relies on outdated equipment or assumptions about wet compression, it’s time to look at the data. The technology has evolved. Today, properly designed systems like MeeFog’s fogging system have proven safe, effective, and profitable, eliminating old myths once and for all.

Real-World Proof: Safe and Reliable Wet Compression

MeeFog Wet Compression Systems have logged hundreds of thousands of operating hours without a single case of compressor blade erosion. The following case studies highlight long-term success in a variety of power generation environments.

Watson Cogeneration Plant, CA

- Power Boost: +10 MW

- Result: Zero blade erosion in over 20 years of continuous operation

“During more than twenty years of operation, the MeeFog wet compression system has not caused blade erosion. We run the system around the clock from June to September and anytime temperatures rise above 50°F.”

— Steve Ingistov, Principal Engineer

Eagle Point, NJ

- Power Boost: +12 MW

- Result: Cleaner compressor and extended maintenance intervals

“Depending on ambient conditions, we get an additional 12 MW from our GE 7EAs. Borescope inspections show the compressor stays cleaner longer, extending time between washes.”

— Jeff Zelik, Plant Manager

Mesquite Block 2, AZ

- Power Boost: +7 MW in under 3 minutes

- Result: Reliable performance and excellent blade condition

“We have not had any issues. The system keeps blades in excellent condition.”

— Todd Hart, Director of Gas Engineering, Onward Energy

These plants prove what years of testing and data confirm: MeeFog’s fogging system for cooling is both safe and efficient. The systems deliver consistent performance, quick response, and zero erosion, even under demanding, high-temperature operating conditions.

Fogging System Engineering That Defines the Standard

MeeFog’s fog spray cooling system is built for precision and longevity. Every component, from the stainless-steel manifolds to the UL 508A-certified pump skids, is designed for industrial reliability.

Here’s what makes MeeFog’s wet compression technology stand out:

✔ 20-micron droplets for fast, complete evaporation, no impaction or erosion

✔ Demineralized water to prevent scaling and mineral buildup

✔ Advanced drainage systems for precise water management

✔ Uniform droplet distribution across the compressor inlet plane

✔ Hundreds of thousands of hours of safe, erosion-free performance

This level of precision in droplet generation and water control makes MeeFog’s systems unmatched in reliability and efficiency. Each fogging system is custom-engineered, factory-tested, and supported by a global network of technical experts.

“MeeFog systems have recorded hundreds of thousands of hours of problem-free wet compression over more than a quarter of a century.”

— Thomas Mee III, CEO, Mee Industries

Long-Term Reliability You Can Trust

In addition to their operational safety, MeeFog systems provide significant economic and environmental advantages. By improving compressor efficiency, the system reduces fuel consumption per megawatt produced. The result: more power with less fuel.

Maintenance requirements are minimal, too. With no oil-filled pumps or disposable parts, MeeFog fogging systems are built to run continuously with minimal attention. Routine checks for nozzle cleanliness and water quality are typically all that’s needed.

MeeFog’s in-house engineering and manufacturing teams have refined every aspect of system design, nozzle alignment, flow balance, and droplet testing to deliver a fogging system for cooling that lasts. Every unit is made in the USA, tested for performance, and backed by decades of proven results.

The Bottom Line

When properly engineered and operated, wet compression is completely safe for gas turbines and far from the erosion risk many once feared. Modern systems like MeeFog’s fog spray cooling system use ultra-fine droplets, clean water, and precise flow control to achieve reliable, repeatable results.

If you’re looking for a low-maintenance, cost-effective way to increase turbine output without investing in major hardware upgrades, MeeFog Wet Compression Systems are a proven choice. Mee Industries leads the industry with decades of experience, advanced droplet control technology, and a flawless record of erosion-free operation.

Ready to Increase Turbine Output Without a Major Upgrade?

Learn more about MeeFog Wet Compression or Talk to our team today.