MOCA Wins Greenest Customer Award

BlogThe Museum of Contemporary Art, Los Angeles (MOCA) is dedicated to collecting and exhibiting art of the 21st century. As such, they needed humidification for their art gallery and museum to best preserve the art. MOCA serves over 250,000 visitors annually and houses roughly 7,000 art objects of different mediums.

The Challenge

In an effort to reduce energy consumption, MOCA needed to upgrade existing air handling units and humidification systems for their art gallery and museum. They needed to do so without having to close the facility, engage in major demolition, or let ambient conditions change.

Museum environments must be strictly monitored and controlled to prevent the deterioration of historic artifacts and art collections. Temperature, relative humidity (RH), and light levels all must be optimized to reduce energy consumption. If humidity is outside of the desired range of 50% to 60%, it can exert dramatic changes on paintings and other objects.

The Solution

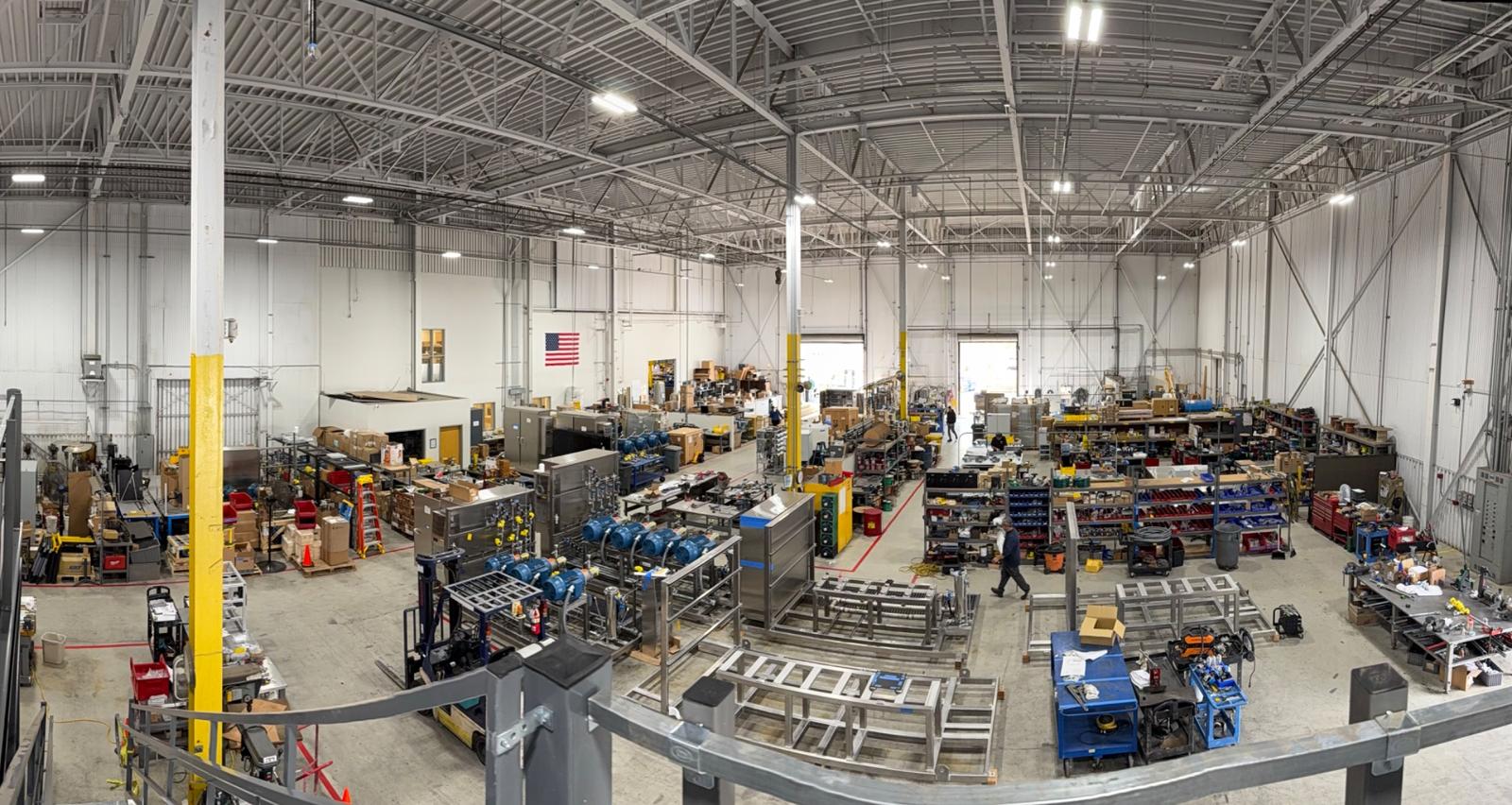

Mee Industries installed an energy efficient fog humidification system to help MOCA reduce energy consumption as well as maintain optimum conditions for their art collections. The facility kept the outer casing of the existing AHUs but changed out the AHU motors, cooling coils, heating coils and upgraded the casing interior and exterior. A new building automation system was also installed, which made it possible to manage energy usage throughout the building.

Energy Savings

Droplet size in fogging systems is the single most important factor governing performance. Smaller droplets mean faster and more efficient humidification, minimal wetting of duct surfaces and greatly reduced water and energy usage. The adiabatic process uses existing heat in the air to evaporate water droplets and increase humidity. This only uses one horsepower of of energy for every 600 lbs of water evaporated.

Contact us to learn more about how you can reduce the energy consumption of your commercial building or industrial space’s humidification.