Steam Condenser Pre-Cooling

Upgrade Condensers on Steam Turbines and Improve Power Plant Reliability

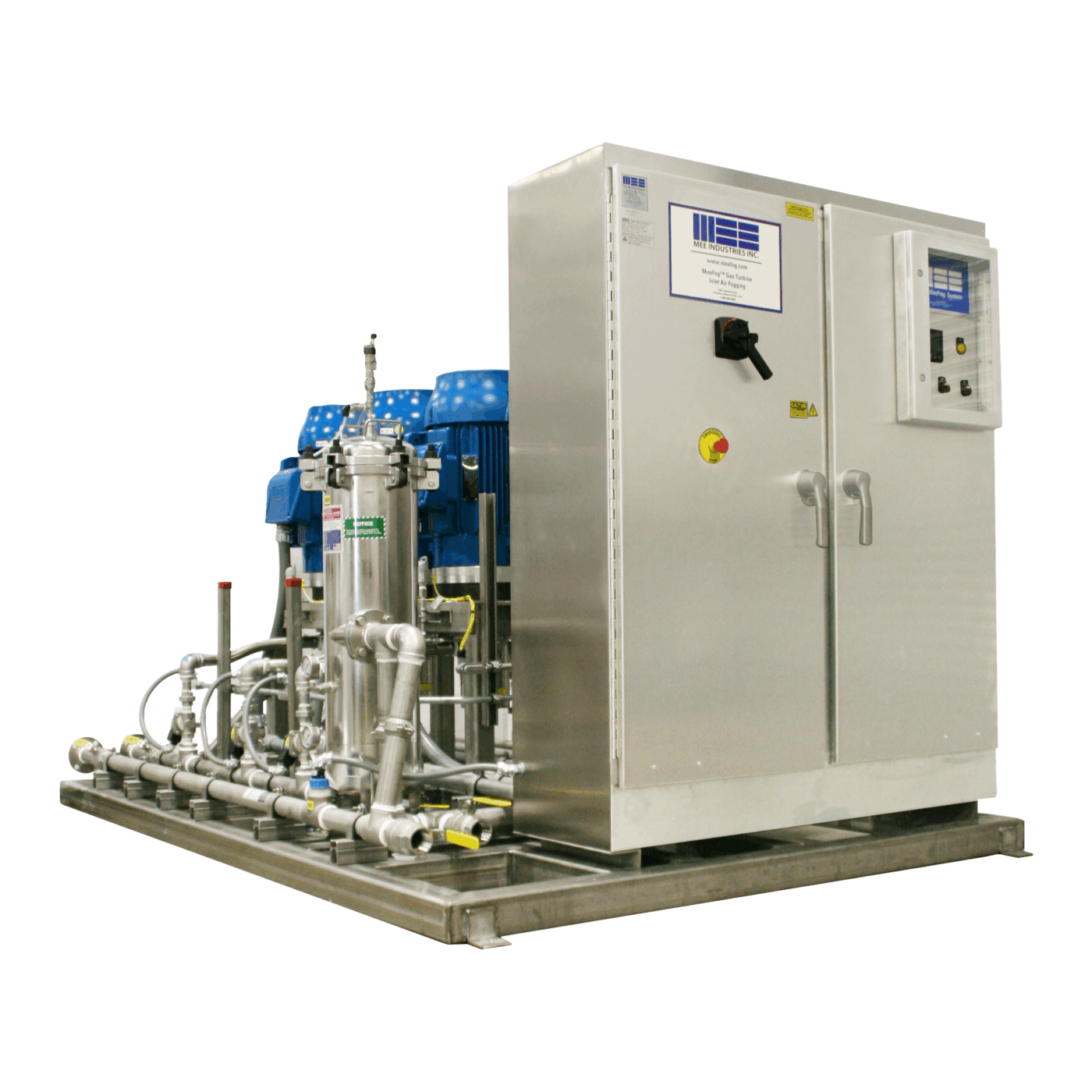

MeeFog systems can be used to pre-cool ambient air for air cooled condensers. Pre-cooling can decrease back pressure on steam turbines improving power plant efficiency. MeeFog systems give maximum cooling without wasting water. Mee Industries would be pleased to provide a feasibility study and detailed proposal for your application. This can include all needed equipment, such as water treatment, storage tanks, controls integration, etc. Mee also provides full installation or supervision, commissioning and testing, operator training and after-sale service and support.

- Cools the inlet air of an ACC and reduces back pressure on the steam turbine.

- Increases heat rejection from existing units.

- Droplets are small enough to evaporate without excessive water fallout.

- The use of demineralized water avoids fouling of the fins and tubes.

We’ll gladly supply a detailed power recovery report for your existing gas turbines including:

- Installed system cost.

- Guaranteed power gain.

- Predicted MW-hr gain per year.

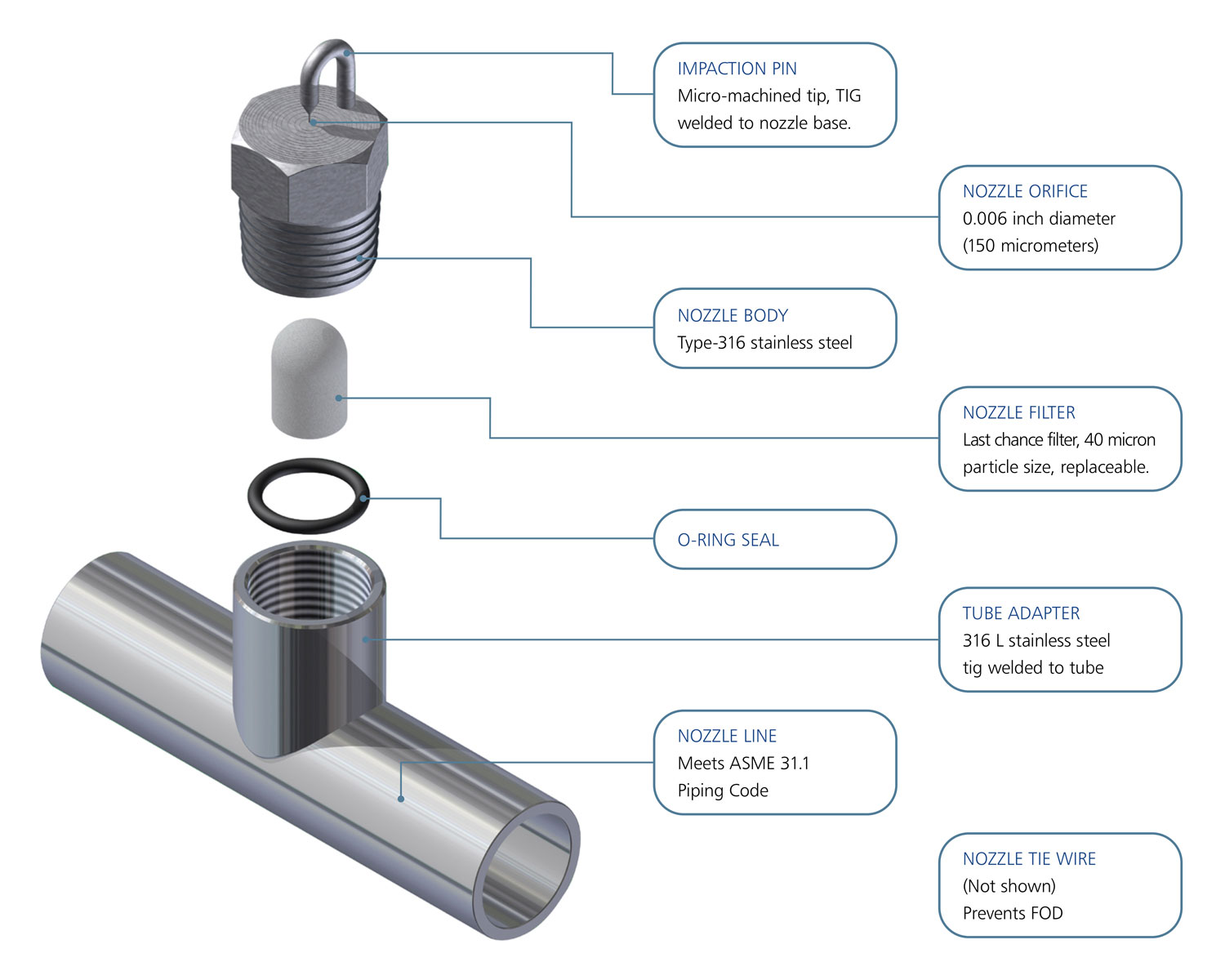

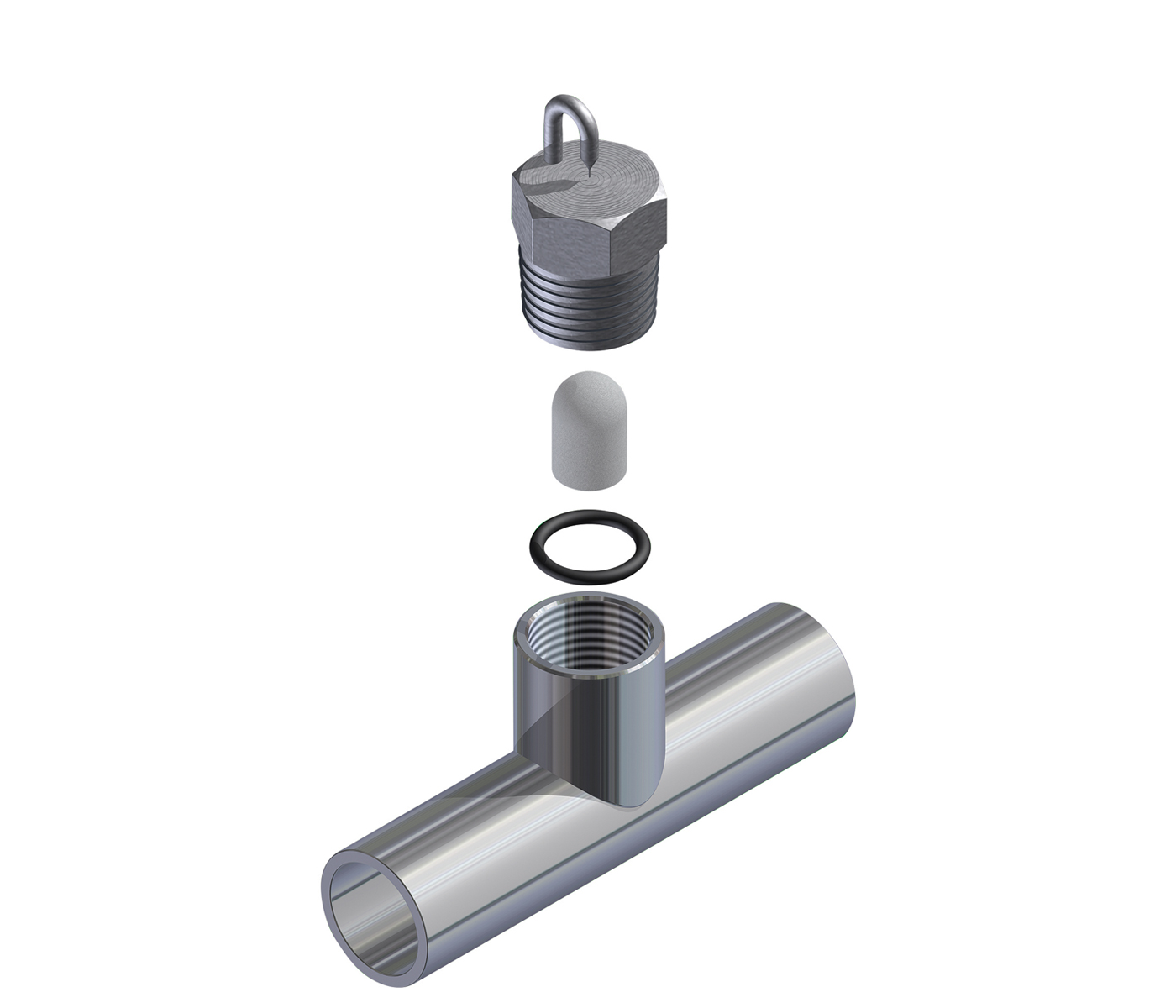

System Overview

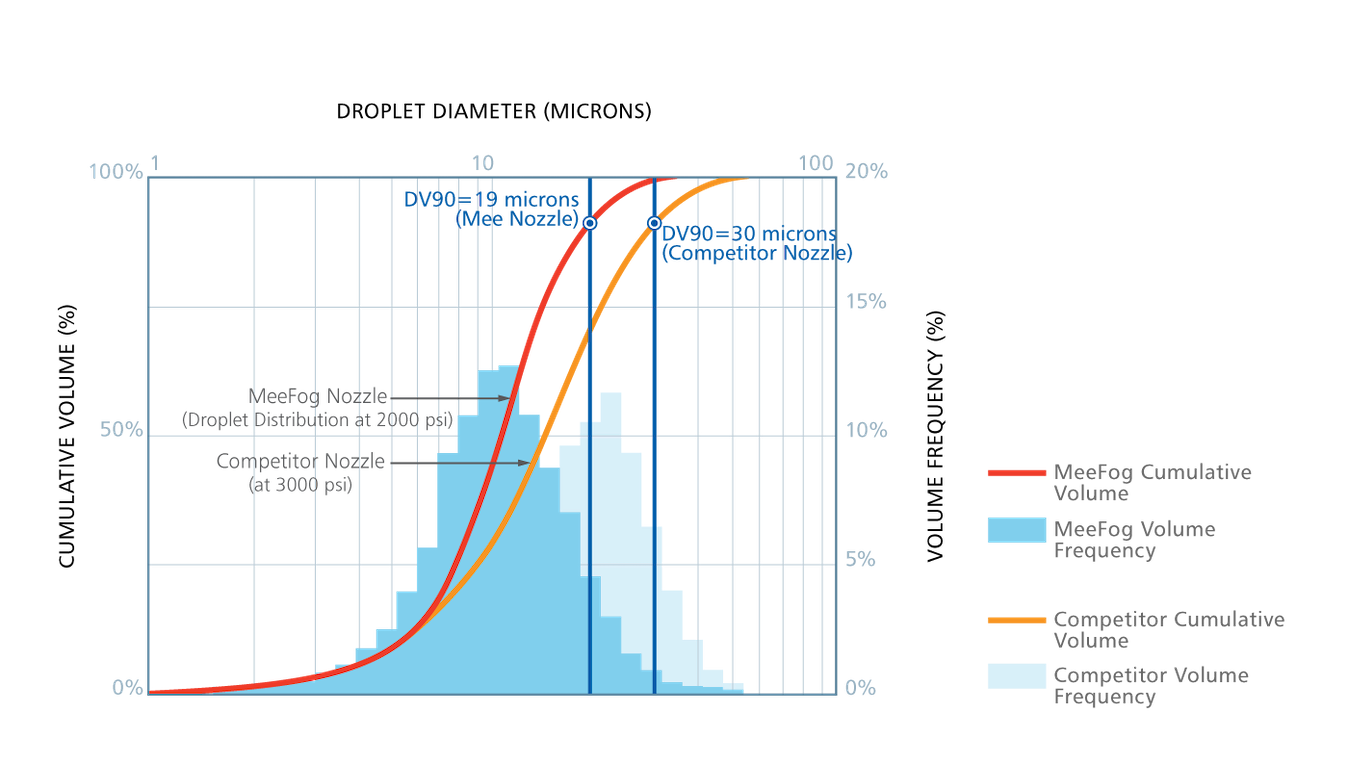

Nozzle Comparison

At an operating pressure of 2000 psi, the resulting average droplet size is roughly one tenth the diameter of a single strand of human hair.

MeeFog System Benefits

- Increases heat rejection from existing units.

- Increases refrigeration capacity.

- Cools and conditions.

- Easy to service and maintain.

- Ultra-fine fog droplets.

- Stainless steel construction.

- Easy to retrofit.

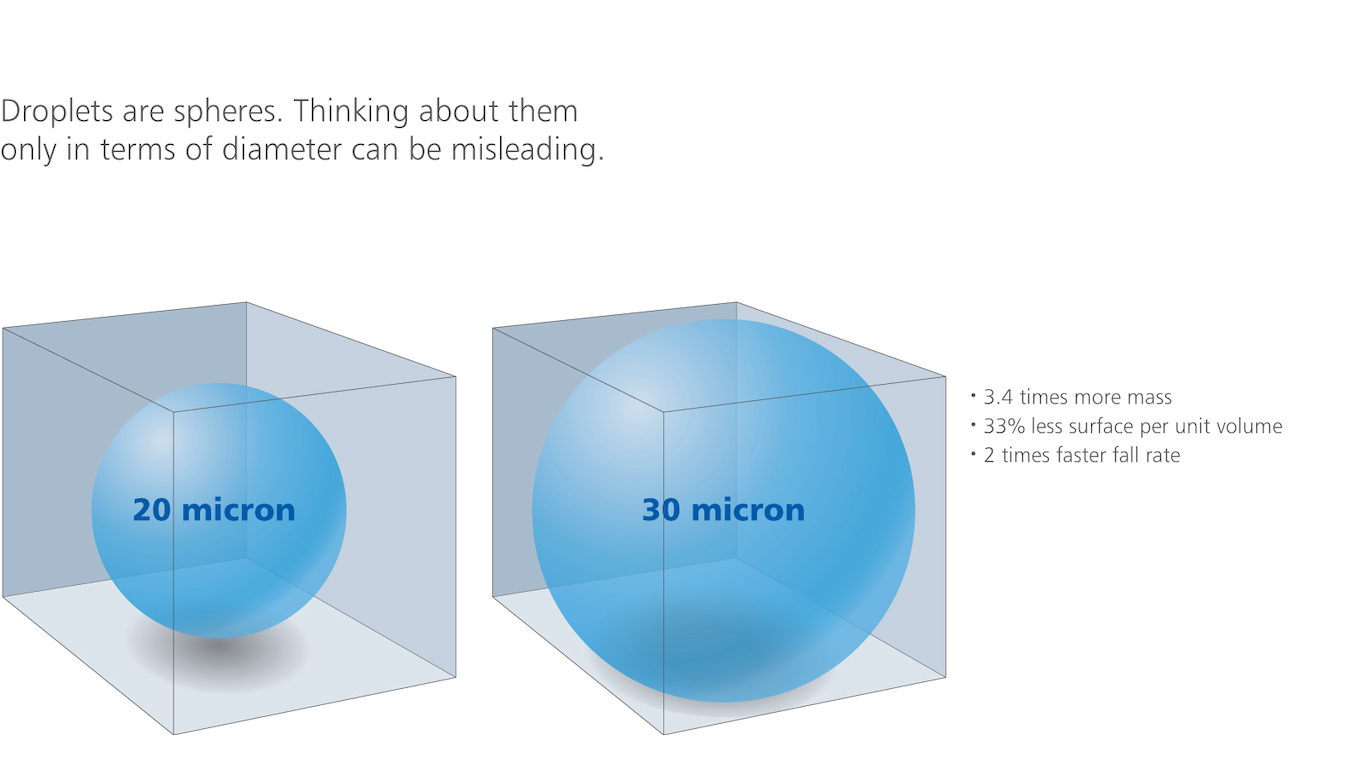

Droplet Comparison

Small droplets have a larger surface to volume ratio compared to larger droplets. This allows them to evaporate much more rapidly than larger droplets.

Want Proof?

We’ll gladly supply a detailed payback analysis report including:

- Installed MeeFog system cost.

- Guaranteed power gain.

- Predicted process gains per year.

Featured Case Study

AC Condenser Pre-Cooling System Provides

16-Month Return On Investment Gudalajara, MX

Project Conditions:

Location: Mexico

Air flow per unit: 400,000 CFM

System Design:

Nozzle count: 338 x 2 located under condenser coils

Cooling capacity: 16 °F

Max GPM/hp: 20 GPM@ 15 hp

A circuit board manufacturer in Mexico installed pre-cooling on two York condensers. According to the plant engineer the system paid for itself in 16 months, giving them about $100K in energy savings per year going forward. The system provides 16 °F of cooling (8.9 °C) for the two condensers.