Our Solution: Steam Condenser Pre-cooling

Gas Turbine Inlet Air Cooling

Decrease Steam Turbine Backpressure With MeeFog

The Benefits of MeeFog Technology:

- Cools the inlet air of an ACC and reduces backpressure on the steam turbine

- The use of demineralized water avoids fouling of the fins and tubes

- Droplets are small enough to evaporate without excessive water fallout

Challenge:

A combined cycle power plant wanted to increase power output without going out of compliance on its stringent environmental requirement.

Solution:

Mee Industries developed a spray system that produces maximum cooling without wasting water. The system was installed to cool the steam condenser, thereby reducing backpressure on the steam turbine and increasing output power. The system was designed to produce fog droplets that are small enough to not fall out of the air stream before reaching the condenser fins. It uses demin water to avoid fouling of the fins and tubes from calcium carbonate.

The Installation:

A combined cycle power plant uses exhaust heat to make steam, the steam is run through a steam turbine, and then through the air cooled condenser (ACC), which makes the steam back into liquid water so it can be used again. In order to cool the condenser coil, fog nozzles were installed above the fans with tubing running the length of the ACC.

The MeeFog system consists of almost 26,000 nozzles installed in six stages. Operating pressure is 470 psi, fog water flow rate is 777 gpm and a total of six 50 horsepower high-pressure pump units were installed. Every pump unit is independently operable and skid-mounted with all necessary ancillary components, motor, controls, etc.

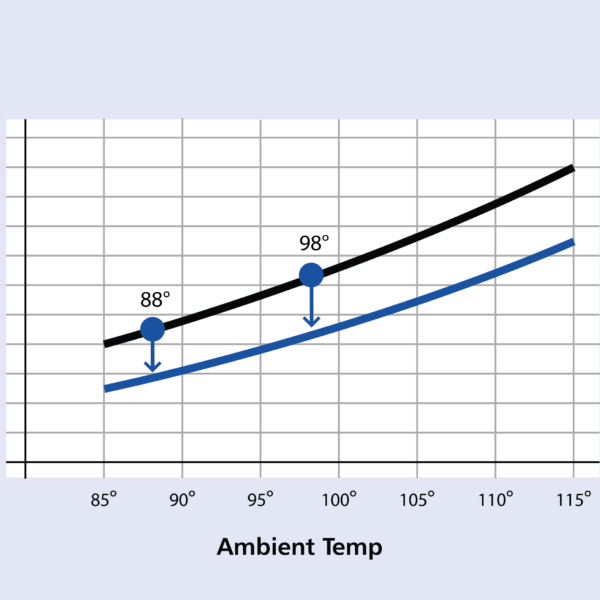

With six stages of fog, the system can be operated according to the capacity of the air to evaporate water. Each of the stages provide 1.7ºF in cooling bringing the total cooling to 10ºF

Effect of Fog Cooling on Air-Cooled Condenser (ACC) Steam Pressure:

Fogging the ACC cools the steam, which decreases steam back-pressure so the steam turbine is not in danger of tripping on hot days. Fogging also increases steam turbine output.

Learn More About Meefog Systems

Read about the benefits of Meefog’s Fog Cooling System from previous successful installations: