Takao Nursery Utilizes Mee Industries Fogging Technology

Agriculture

Three Generations

Howard and Fumiko Takao started a landscape company. In 1960 the company evolved into Takao Nursery, a wholesale groundcover nursery in Torrance, California. The business kept growing and was relocated to Fresno, California by 1979. They installed the first MeeFog system in their nursery in 1985 and that system is still operational today.

Danny Takao, Howard, and Fumiko’s son, took over operations in 1980 and transitioned the business into full-time perennial propagation. His initial focus was on growing new, patented varieties from breeders around the world. He now also grows many drought-tolerant plants to fulfill the demand called for by the trend toward low-water landscape design in California.

The Challenge:

Summer temperatures in Fresno are often over 100 °F. Takao Nursery needed to control humidity and temperature in order to have a successful greenhouse propagation business.

The Solution:

Takao installed Mee Industries’ Fog Technology to provide uniform cooling and humidification over their propagation beds. They are able to meet customer demand by supplying consistently high quality plants with faster turnover rates.

Today, under the growing influence of third-generation family member Lisa Takao-McCall, the Fresno greenhouse facility concentrates on propagating California natives and drought-tolerant plants. The MeeFog fogging technology allows them to grow many varieties that are difficult to propagate.

Thirty Years of Fog Technology:

Takao Nursery has 120,000 square feet of Agra Tech greenhouses and 40,000 square feet of cold frames, under cover. The original MeeFog system was installed in the 1980s and was designed to humidify 25,000 square feet of the greenhouse. An array of 240 fog nozzles spans the area, with each nozzle covering about 100 square feet of plant beds. The nozzles are mounted on copper tubing installed about 10 feet above the benches and when operating, the ultra-fine droplets form a fine mist that fills the entire volume of air, evaporating quickly to increase humidity and cool the air. In the early years Danny Takao tried other misting systems, “We’ve looked at other systems but always stayed with MeeFog.”, he said. The MeeFog system is used for both cooling and humidification, and because of the high-pressure and tiny droplet size, the system is the most effective. “We are starting to do more drought tolerant plants so we need to do precision adjustments with the humidity to get better take on those plants. It would be impossible to do that with a conventional misting system.” In 2004 Danny upgraded his system with a more energy efficient 5hp 3-phase motor and 1050 model pump.

“We’ve been using the Mee Industries Fogging Technology for over 30 years now. My daughter is taking over now so we’ll continue with what works for another 30 years.” — Danny Takao, President

The MeeFog Difference:

Applying the Meefog fogging technology creates an ideal environment in the greenhouse, which prevents cuttings from drying out. The super-fine fog doesn’t over-wet the growing medium, thus eliminating the worry of disease. Takao Nursery experienced a rapid return on their investment in MeeFog, because of the increase in their plant production, and the minimal energy and maintenance costs. They can grow more difficult plants than before, and propagation areas achieve up to a two times faster turnover rate. Danny has plans to install another MeeFog system next year that will be synchronized with attic fans for precision cooling during the hot summers. He says, “We’ve been using the Mee System for over 30 years now. My daughter is taking over now so we’ll continue with what works for another 30 years.”

The Right Size for Any Project:

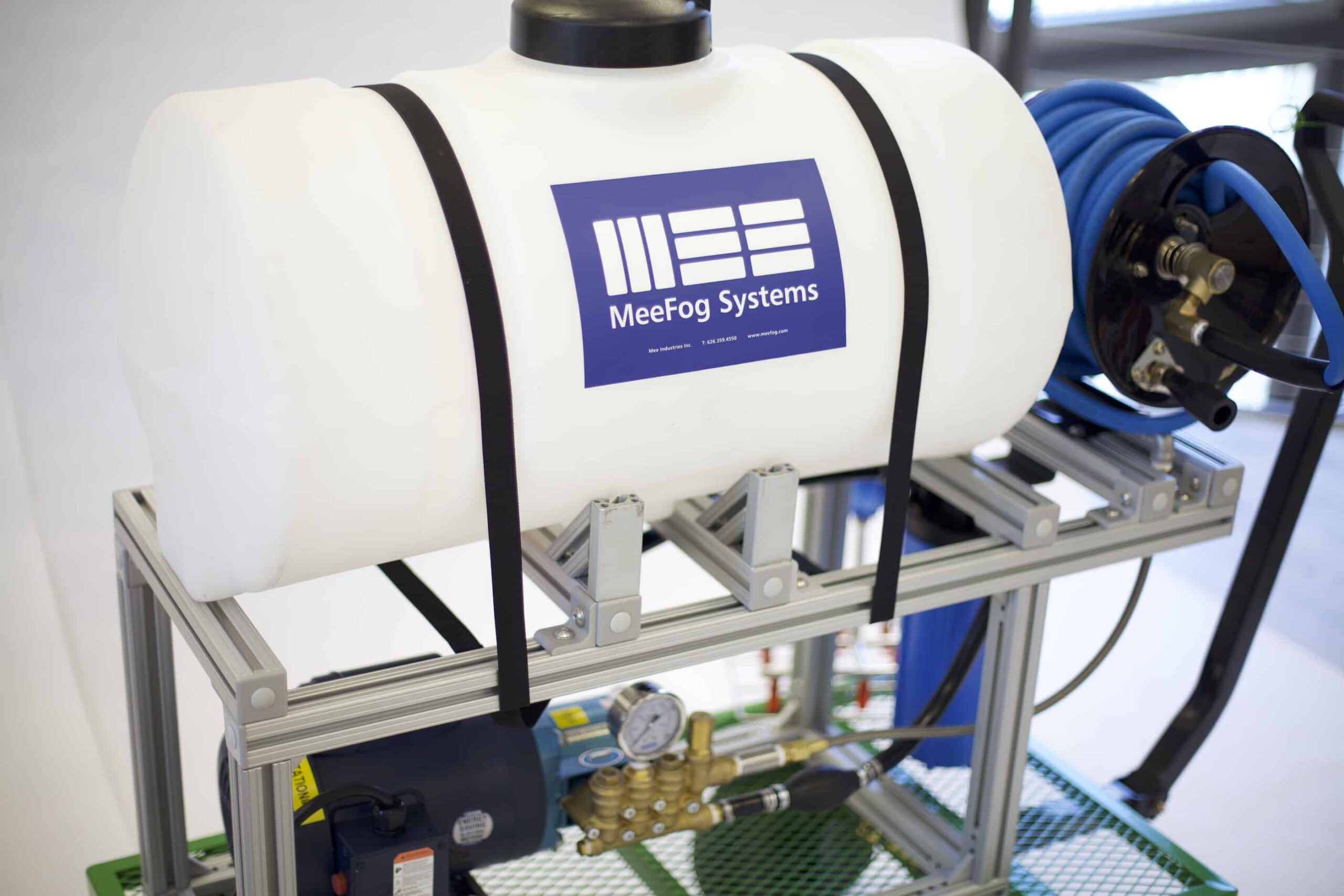

MeeFog greenhouse cooling and propagation humidification systems are custom engineered to the exact needs of each project. Mee Industries will analyze the supply water and provide a water treatment system if needed. Treated water eliminates mineral dusting on plants and reduces fog nozzle maintenance.

Learn More About Meefog’s Fog Technology

Discover more projects and case studies documenting successful installations of Meefog Systems Fogging Technology.

Request a Quote

Find out how you can apply Meefog’s Fogging System for your agricultural humidification needs here by filling out this form: