Energy Efficient MeeFog System Allows Amherst College to Humidify the New Science Center

UniversitiesScience Center Expansion

Founded in 1821 with a focus on liberal arts, Amherst College has seen an 85% increase in enrollments in Science, Technology, Engineering and Math (STEM) classes during the past 15 years. Consequently, a new Science Center was opened in the fall of 2018 that embraces sustainability and efficiency standards.

The facility was designed by Van Zelm Engineers of Farmington, Connecticut. Having designed many campus and district central energy plants and distribution loops using a sustainable approach, they were able to reduce energy usage by 73% compared to the typical science building through a variety of features. These include:

- More efficient systems for building HVAC

- Individual lab hood controls

- An insulating building envelope

- A floor plan that groups specialized labs

- Rainwater harvesting (to reduce water consumption by a million gallons a year)

- A rooftop solar array (to provide one third of energy use)

Additional solar energy comes from the Farmington Solar project in Maine via a 20-year power purchase agreement (PPA) for 10,000 megawatt hours (MWh) of electricity. This PPA cuts carbon emissions by 3,200 metric tons per year and greenhouse gas emissions by 17.5%. The rest of the needed power (about half) is derived from a combined heat and power (CHP) plant on campus which is to gradually be phased out.

“Deriving such a significant amount of Amherst’s electrical needs from this renewable source represents a major step in the College’s Climate Action Plan (CAP),” said James Brassord, chief of campus operations. “This electricity will be used to power the infrastructure that will allow us to decarbonize the campus.”

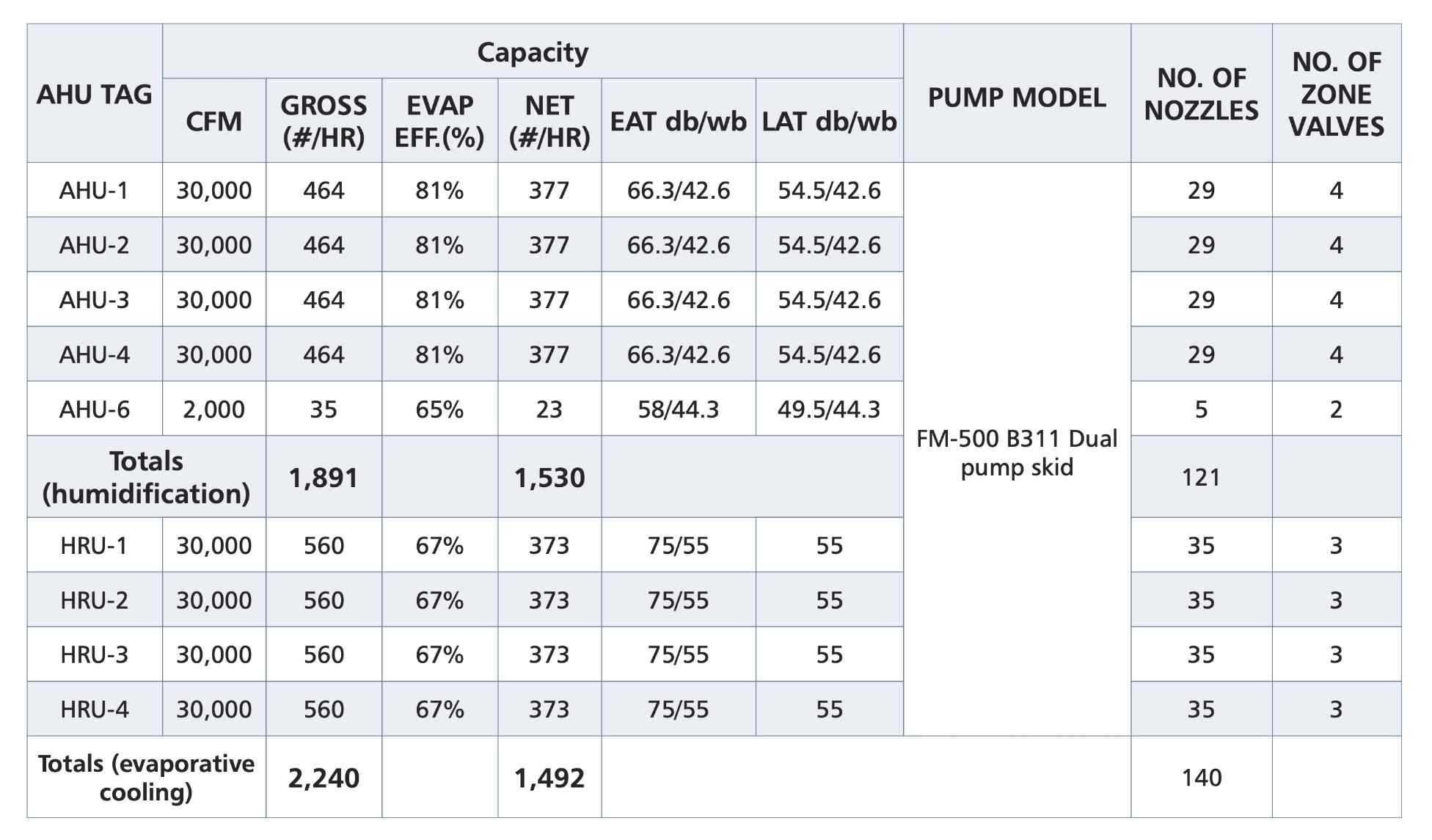

Amherst College Air Handling Units:

- Humidification and Cooling Supplied to five air handling units (AHUs) and four heat recovery units (HRUs).

- Consisting of one pump rack with dual 5 GPM pump units, 5 hp motors, VFD & pressure transducer.

- The Mee pump units are mounted on one stainless steel pump rack with single-point power connection and PLC that monitors both pump units and provides auto-switchover.

Project Conditions:

Entering air conditions: 66 °F db / 44° F wb

Leaving air conditions: 55° F db / 42° F wb

Mee’s scope of work: Supply of fog pump

rack, staging valves, nozzle manifolds, and mist eliminators.

Max fog system power: 2 x 5 HP

Humidification stages: 15

Fog System Design:

Humidification

MeeFog Nozzle Count: 121

Humidification capacity: 1,530 #/hr

Evaporative Cooling

MeeFog Nozzle Count: 140

Cooling capacity: 20° F

Building Efficiency Improvements

Meanwhile, tangible reductions in energy load and carbon footprint are being achieved through building energy efficiency improvements. The Science Center labs have a ferocious appetite for cooling. Various regulations and standards demand no recirculation of inside air in the labs. Thus, new ambient air must be continually fed in. During the summer months, that air is hot. A lot of energy is required to bring down the temperature to a comfortable level, courtesy of a Central chiller plant Campus Loop.

The Science Center design included features that reduce the cost burden (and hence the carbon footprint) of the chiller plant. This is achieved via an exhaust heat recovery system and a run-around coil. This solution works well but struggles during the hotter summer months. By adding supplementary evaporative cooling to cool the air before it hits the run-around coil, energy costs can be greatly reduced. Overall, the combination of a run-around coil and fog-based cooling of exhaust air slashes cost by about one third with a corresponding reduction in the carbon footprint.

Improved Exhaust Heat Recovery System Design

Van Zelm Engineers of Farmington, Connecticut, has designed many campus and district central energy plants and distribution loops using a sustainable approach. Eric Fontaine, P.E., Senior Associate at van Zelm Engineers, finds that designing a sustainable laboratory building presents numerous challenges.

“Perhaps the biggest challenge is reducing the energy used for conditioning the ventilation air in a building with inherently high ventilation rates and potentially contaminated exhaust streams while satisfying code requirements and maintaining a safe environment,” said Fontaine. “Selecting the proper energy recovery system approach represents the most important decision in the design of an energy efficient laboratory HVAC system.”

Based on his company’s analysis of heat recovery options for the laboratory exhaust systems, the most efficient way to achieve this is by feeding hot exhaust air through a run-around coil loop. The loop moves heat from one air stream to another via heat exchangers. This has been found to be the only efficient way to transfer heat between two air streams that cannot be directly connected for reasons of safety or practicality. Pipework is charged with a heat exchange fluid such as water or glycol, which picks up heat from the exhaust air coil and gives up heat to the supply air coil. This is connected to the chiller system to raise efficiency and lower the energy load on the chiller system. As the two air streams are separate units, there is no threat of exhaust contamination.

Konvekta of Princeton, New Jersey, manufactures a glycol run-around loop that has proven successful in many facilities throughout Europe and is now gaining traction in US colleges, labs and hospitals. This closed-loop system extracts energy in the form of cold or heat from the exhaust air of buildings and returns it to the supply air efficiently. This is achieved via well-designed heat exchangers coupled with optimization and control software. The heat exchangers have headers on both sides to create countercurrent flow. This makes the units compact and efficient. Software takes into account the building configuration as well as meteorological data for an entire year. This enables its operation to be adjusted appropriately with the changes in the seasons. Van Zelm Engineers have more than 15 years of experience with this system.

“The controls calculate the amount of energy available at any time and make adjustments to recover as much energy as possible,” said Fontaine. “The typical run-around loop can perhaps reach 55% energy recovery whereas Konvekta can reach 70% and beyond due to its built-in intelligence.”

Cooling Augmentation for Added Efficiency

The heat exchange efficiency of the system is further increased by precooling the exhaust air using a fog cooling system by Mee Industries of Irwindale, California.

“In summer, the performance of traditional glycol loop systems is limited by the intake and exhaust airstream temperature difference, resulting in minimal energy recovery,” said Fontaine. “MeeFog brings the exhaust air temperature down before it reaches the loop, which increases the amount of energy you can recover.”

Fogging adiabatically cools the exhaust air by 10 to 15 degrees F. via the evaporation of microfine fog droplets before it hits the glycol loop exhaust energy recovery system. Thus, the workload on the large centrifugal chillers used to cool the outside air is considerably reduced.

The fogging system consists of an array of fog nozzle lines installed in the exhaust air flow prior to it reaching the glycol loop. As the droplets are tiny, they stay airborne to maximize the evaporative cooling potential. A series of staging valves are included so that the right amount of fog can be applied to achieve the desired level of cooling. As the summer afternoon temperatures rise, more stages are opened.

Fog systems atomize high-pressure water (1000 to 2000 psi) through a network of 316 stainless steel tubes and impaction-pin fog nozzles which feature an orifice with a diameter of 150 micrometers. The result is a fog containing billions of ultra-fine droplets of pure water, averaging about ten microns in size. This fog is injected into the exhaust air where it evaporates to lower the temperature and increase the humidity of the air. The spray system controls ensure it produces maximum cooling without wasting water. Savings in running costs mean that a fogging system will typically pay for itself within one year. Energy consumption is nominal.

College Lowers Its Carbon Footprint

Amherst College in Massachusetts has embarked upon an ambitious plan to greatly reduce its carbon footprint by 2030. Major progress has already been made courtesy of a new science center that incorporates a great many sustainability features. These serve to both lower energy usage and improve overall efficiency.

An upgrade to the cooling system of the science building reduces the amount of energy required during the summer. A combination of a glycol loop and a fog-based evaporative cooling system augment the electric chiller plant.

“We developed and analyzed multiple heat recovery options for the laboratory exhaust systems and ultimately selected the combination of the glycol run-around system combined with the fogging system for indirect evaporative cooling,” said Fontaine of van Zelm, who works as project manager for the Science Center project. “Using MeeFog in the exhaust airstream during summer improves the heat recovery efficiency at peak design condition by over 50% and increases annual recovered cooling energy by over 400%.”

For the Amherst College Science Center, that translates into approximately 45 additional tons of peak chilled water savings. The total cooling recovery was calculated at 885 MM Btu in 2021 and 1,119 MM Btu in 2022.

“These numbers would have been at least 80% lower without MeeFog due to the outside air temperatures of 70 to 90 degrees F., where the system couldn’t recover any cooling energy without fogging,” said Fontaine. “The annual savings from the MeeFog system at Amherst amount to an average of 800 MM Btu.”

Raising Campus Efficiency

Van Zelm has worked on many higher education and other campuses. Fontaine noted that many facilities are already using evaporative fogging to humidify their environment in the winter when the air can become very dry. He suggested gaining further value from that fogging system by extending its usage into the summer months to augment a run-around loop.

“If you are already using fog for humidification in winter, all you have to do is get some extra piping for summer and you reduce your first costs and greatly increase the financial picture,” said Fontaine.

Those without fog-based humidification can still gain a fast return on investment. Van Zelm recently evaluated a system at a large university in Massachusetts that needed the system installed from scratch. Per Fontaine’s calculations, the energy recovery savings would pay for fogging within about three years.

“All energy intensive facilities such as laboratories, hospitals and industrial sites that include run-around heat recovery systems should consider adding a fog-based adiabatic cooling system,” said Fontaine. “It is relatively easy to accommodate and the payback rate for the system is favorable.”

Jonathan VanDine, owner of JVD Industrial (Windsor, CT) acted as the manufacturer’s rep for the fogging system. He explains how it works: Four heat recovery units (HRUs) have fog nozzle arrays stationed inside to spray the exhaust air with fog. In summer, the exhaust air from the labs ranges between about 72 ℉ and 76 ℉. Fogging drops that number down anywhere from 60 ℉ to 64 ℉ before it is drawn across the heat exchanger to be applied to the inlet outside air supply.

Jonathan VanDine, owner of JVD Industrial (Windsor, CT) acted as the manufacturer’s rep for the fogging system. He explains how it works: Four heat recovery units (HRUs) have fog nozzle arrays stationed inside to spray the exhaust air with fog. In summer, the exhaust air from the labs ranges between about 72 ℉ and 76 ℉. Fogging drops that number down anywhere from 60 ℉ to 64 ℉ before it is drawn across the heat exchanger to be applied to the inlet outside air supply.

“Continuous air replacement is the top operating expense of the Science Center,” said Amherst College Science Center Specialist Kyle Mangini who looks after all laboratory and mechanical systems.

Mangini said that three electric centrifugal chillers of around 500 to 600 tons each are used to provide chilled water to the entire campus. One of these chillers is used to cool anywhere from 85,000 to 100,000 CFM of outside air needed by Science Center labs.

“The glycol loop helps to reduce air replacement costs and is almost always running,” said Mangini.

In July when temperatures can reach 80 ℉ or more, up to 500 tons of cooling might be needed for outside air to the lab. The fog system for exhaust air operates seasonally. It runs from May to September.

“Once we start the fogging system, the tonnage needed for cooling drops to around 150 to 250 tons,” said Mangini. “We get a lot more cooling out of the convective glycol system due to fogging at the exhaust level.”

He estimates that the average tonnage curtailment from the Mee/Konvecta systems runs at around 30%. If the chillers are operating at 250 tons per day, MeeFog System’s High-Pressure Water Atomization reduces the load by about 80 tons and the Konvecta system by about 20 tons on a summer’s day due to the evaporative cooling of exhaust air.

“Chiller energy usage can be brought down by as much as a third using this cooling augmentation approach,” said Mangini.

Seasonal numbers show a reduction of about 36,000 tons of chiller cooling due to fog alone. Data pulled from building systems at Amherst College from the summer of 2022 shows a reduction of 17,049.5 tons of chilling load when only the glycol loop is running and 53,119.5 tons reduction when both fog and the glycol loop are operating. The numbers for fogging increase during the hottest months and tail off in May/June and September.

“Eliminating an additional 36,000 tons of annual chiller load is huge for us,” said Mangini. “As well as representing a major dent in the annual bill for continuous air replacement to the labs, the combination of MeeFog and a glycol loop brings about another big drop in our carbon footprint.”

Amherst College also uses MeeFog HVAC Systems for building humidification in the winter. From roughly October to June, fogging is used inside five air handling units (AHUs) to raise the dry winter air to the desired level of humidity. “We need humidity in labs to avoid static electricity that can damage computers and other equipment, and in our mill so wood doesn’t get too dry,” said Mangini. “Our physics department wants 40% humidity, and we can’t reach that without MeeFog.”

He added that as another aspect of the college’s CAP, fogging may eventually replace steam-based humification systems used at other parts of the campus such as the Art Museum building and other facilities.

Future Plans for Geothermal

While these systems have already eaten into the carbon footprint of the campus, Amherst has even bigger plans. It aims to achieve carbon neutrality by 2030. A major part of this is converting from steam heating powered by fossil fuels to low-temperature hot water heating. This project is being staged over seven years and is scheduled to be completed by 2030.

It will require conversion of the existing heating system as well as the laying of new pipes underground to connect all campus buildings to each other and the low-temperature hot water system. To complete the transition, Amherst will drill geothermal wells and install electric heat pumps. Water will be heated to 130 ℉ to provide heat to buildings.

“We just began removing steam heating gradually from the campus,” said Mangini. “The transition to geothermal energy means the college can reduce its slash carbon dioxide emissions by another 14,000 tons per year.”

Cost Breakdown for Fogging

- Cost of the MeeFog System taking into account the equipment, the mechanical contractor, added construction costs to the owner, labor, engineering, and administrative costs: Approximately $300,000 for a system similar to Amherst (the MeeFog spec list came to $192,000).

- Return on investment: $500-$1500 per ton of building capacity saved depending on arrangement, existing infrastructure and build-out costs.

- Operational costs for fogging: about 7-10HP of pump kw plus the cost of reverse osmosis water.

If the building already has a glycol loop-style energy recovery system, the payback for MeeFog should be realized within one cooling season in New England. If an energy recovery system needs to be added, a longer payback timeline would be required.

Interested in how Meefog Systems can help meet your company’s HVAC needs?

Read more about successful Meefog Fogging Systems Installations. We’re the experts in fogging.

Humidification Equipment Schedule

Interested in how Meefog Systems can help meet your company’s HVAC needs? Read more about successful Meefog Fogging Systems Installations. We’re the experts in fogging.