Water Treatment System

When Clean Matters

Water purified with reverse osmosis (RO) is recommended for many MeeFog applications that require a clean environment with air that has low particulate concentrations. Removing minerals and dissolved solids from supply water will achieve some of the highest purity of water and reduce routine maintenance. Mee Industries provides the ultimate in project execution. From design to supply, installation and after sales service there is a single supplier—a single point of contact.

Backed by over 50 years of experience, Mee Industries has pioneered the use of fog humidification and applies its experience with water treatment to customizing the exact system required for your application.

Clean and Simple

Benefits of Using MeeFog Water Treatment:

- Ultrapure water with reduced chemical usage and reduced maintenance hazards.

- No acid/caustic ion-exchange.

- All controls integrated for set-and-forget ease of use.

- Optimized design ensures right sizing of tanks and treated water supply.

- Factory tested in actual configuration to ensure full functionality and optimum performance.

- PLC communicates with fog system to ensure adequate water supply at all times.

- Advance alert on potential water shortages.

- Single skid design makes installation easy.

- Operates at full-capacity even under cold water conditions.

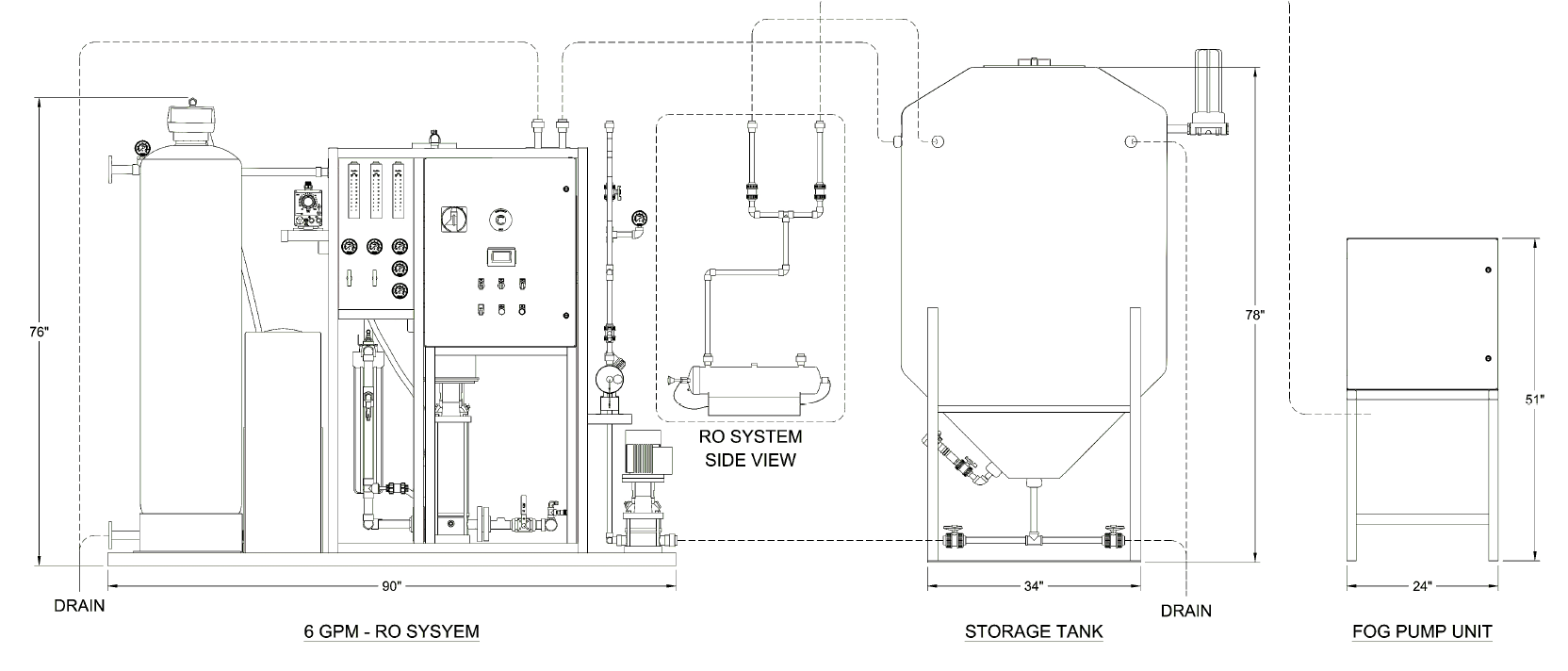

Reverse Osmosis Water Treatment

Water purified by Reverse Osmosis (RO) is recommended for most MeeFog systems. Removing minerals and dissolved solids from supply water achieves the highest purity of water and effectively reduces routine maintenance.

Each RO system is offered with various levels of pre-treatment customized to your project to ensure extended and enhanced water purification.

Standard Features:

- Rugged corrosion resistant stainless steel frame.

- Automated alarmed shut-off and divert valves.

- PLC controller with transmitters.

- Low fouling, energy saving TFC membranes.

- Panel-mounted pressure gauges and flow meters.

- Panel-mounted control valves.

- 5 micron inlet filter.

- Touch screen HMI control interface.

- Automated membrane flushing.

Add-On Features:

Can Be Integrated onto RO Skid

- UV re-circulation system.

- Storage tank with adjustable level control for auto start/stop.

- Re-pressurization pump.

RODI Skid Reverse Osmosis and De-Ionizing

Reverse Osmosis and De-Ionizing (RODI) purification systems effectively remove contaminants such as silica, iron, hardness, sodium and chlorides and are recommended for all gas turbine inlet cooling systems. Removing these minerals and dissolved solids from supply water achieves the highest purity of water and effectively reduces routine maintenance.

Each RODI system is offered with various levels of chemical and mechanical pre-treatment customized to your project to ensure extended and enhanced water purification and optimal performance of the gas turbine.

Standard Features:

- Rugged corrosion resistant stainless steel frame.

- Automated alarmed shut-off and divert valves.

- Low fouling, high-rejection TFC membranes.

- Panel-mounted pressure gauges and flow meters.

- Panel-mounted control valves.

- Double pass RO.

- Touch screen HMI control interface.

- PLC controller with frequency controlled variable speed pump/motors.

- Automated membrane flushing.

- No chemical regeneration required.

- Integrated RO/EDI skid designs.

Add-On Features:

- Pre-treatment filtration.

- Pre-treatment chemical dosing.

- UV re-circulation system.

- Storage tank with adjustable level control for auto start/stop.

- Re-pressurization pump.

- DI water polishing to ultra pure standards.

- All stainless steel piping.

- Computerized control systems for remote monitoring, programming and data logging.