Facebook Upgrades Outside Air Cooling System at Prineville Data Center

Data Centers

Prineville Data Center

Challenge

After helping Facebook design a highly efficient cooling and humidification system at the Prineville data center in 2011, the company wanted to boost efficiency even further and lower system maintenance requirements.

Solution

New pumps were recently introduced into the MeeFog system at Prineville along with system modifications to lower maintenance costs and improve Power Usage Effectiveness (PUE).

The Physical Site:

The Prineville data center complex is in the high desert region of Oregon where the summer temperatures generally range between 80-90°F, with highs sometimes exceeding 100°F. The original data center was designed in 2011 to achieve the highest levels of efficiency. The 330,000 square feet facility boasts an impressive Power Usage Effectiveness (PUE) of 1.15 well below the industry average of around 1.6. That means that for every 100 watts going to the computing equipment, only 15 watts goes to cooling, lighting, UPS and power distribution.

Instead of relying on traditional, energy hogging Computer Room Air Handler (CRAH) units, Facebook adopted a sustainable approach by using outside air to minimize cooling costs. The design integrates a single system for both cooling and humidifying the entire building, including the IT equipment racks.

The system is divided between two floors. An upper floor is devoted to pulling in outside air, filtering it, cooling it and humidifying it before sending it down to the lower floor where the servers are located. Notably, no duct work is needed. Instead, the air handling system uses fans to create a positive air pressure in a plenum above the cold aisles. This reduces the energy required at the server to pull the air past the components and keeps energy consumption low. The upper air handling deck has a series of louvers to control the amount of air pulled into the building and the amount of hot air from the servers that gets exhausted outside or recycled back through the servers. This innovative approach allows the Prineville data center to operate year-round without mechanical cooling, even during the hottest summer days.

The Installation:

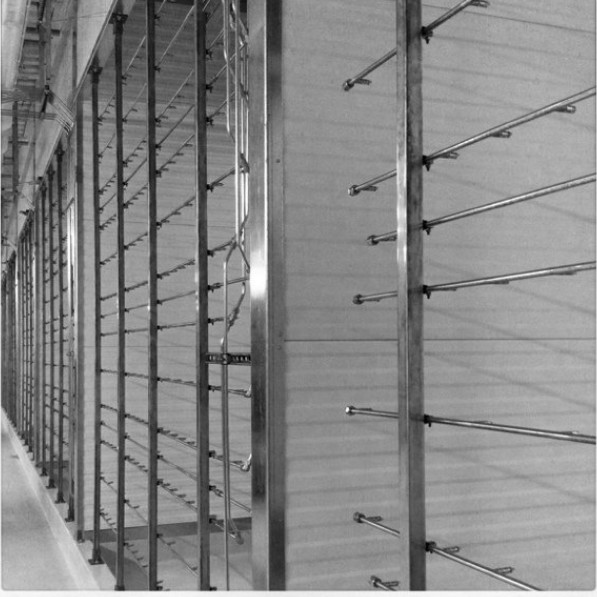

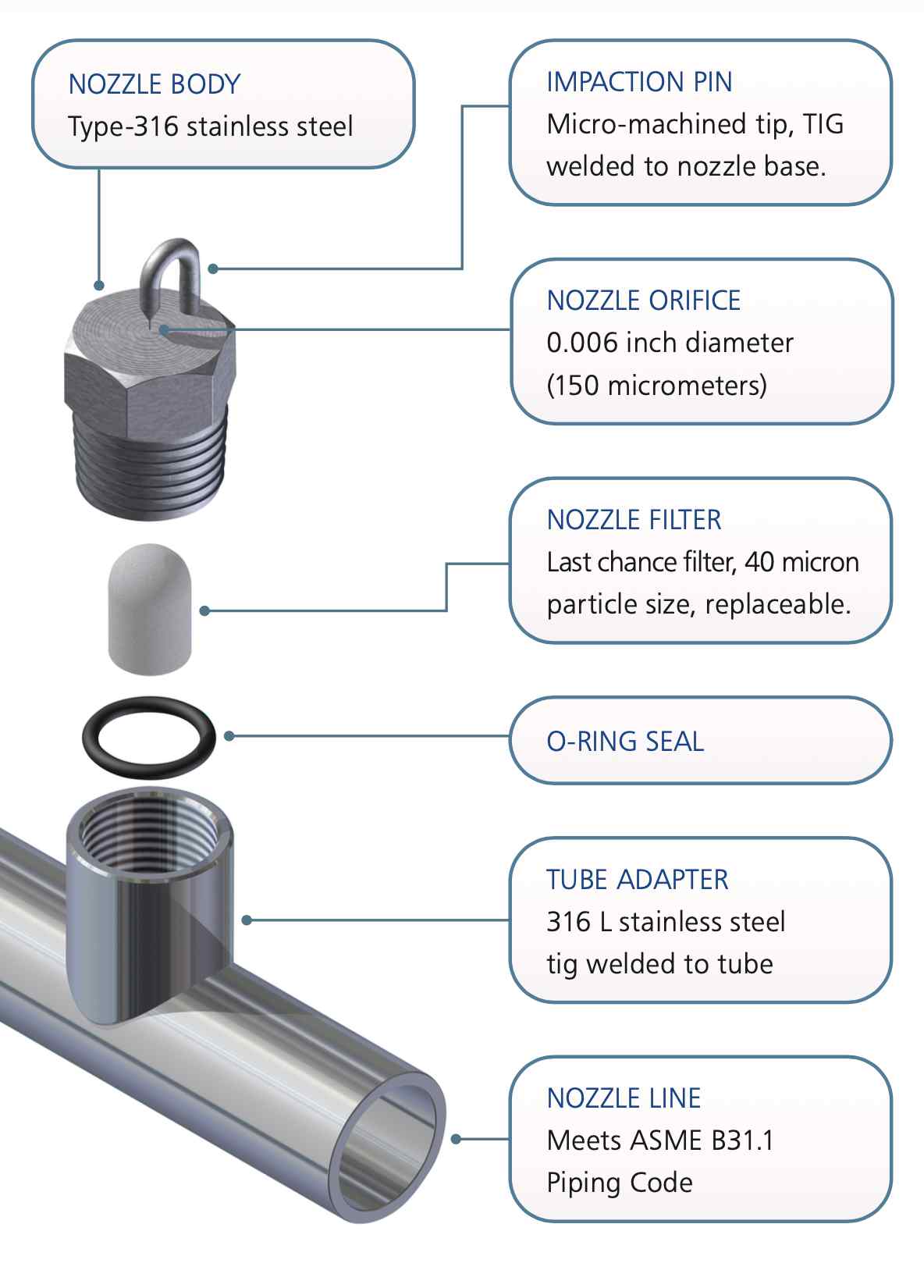

The heart of Prineville’s cooling and humidification system is the custom-built MeeFog system, which features over 6,600 nozzles providing precise, multi-stage cooling and humidification. Originally, the system utilized 56 x 7.5 HP positive displacement fog pumps, each equipped with variable frequency drives. These pumps deliver 7.62 gallons per minute (gpm) of fog at 1,000 psi. Two pumps serve each air handling unit (AHU)—one in use, the other on standby. With a total of 28 AHUs, these pumps send water through stainless steel tubing to a series of impaction-pin nozzles. These nozzles convert the water into a micro-fine fog, which rapidly evaporates and cools the air. The fogging process cools air to the desired temperature of 80.5°F, in line with ASHRAE standards, while maintaining the necessary humidity levels. In the dry Prineville region, with only 10 inches of annual rainfall, the MeeFog system prevents static electricity buildup by adding moisture, keeping humidity within the 45%-55% range to protect sensitive IT equipment.

Recent Upgrades:

While the original Prineville data center set a high standard for energy efficiency with its low PUE, Facebook aimed to improve the system further by reducing its maintenance needs. This led to a collaboration with Mee Industries to simplify maintenance operations and lower labor requirements.

The original MeeFog cooling and humidification system used oil-lubricated pumps, which required periodic oil changes as a part of the regular maintenance schedule. To streamline this process, the oil-lubricated pumps were replaced with water-lubricated units from Danfoss Pumps, reducing the maintenance burden and eliminating the need for oil changes.

However, this upgrade meant further modifications to the system to accommodate the new pumps. For example, the new water lubricated pumps cannot slow down as well as the previous models, sometimes resulting in excessive water being pumped, which could cause the pumps to overheat. To address this, heat exchanger assemblies were added to all pump skids, allowing for effective cooling during low-load conditions. As a result of these upgrades, the Prineville data center continues to meet stringent PUE standards while the fogging system now requires minimal maintenance.

The Benefits of MeeFog technology:

The data center’s temperature is maintained at 80.5°F in accordance with ASHRAE standards. The data center operates year-round without using mechanical cooling, even when summer temperatures reach as high as 110°F. Fogging replaces traditional, refrigerant-based data center computer room air handling (CRAH) units. The facility achieves a Power Usage Effectiveness rating of 1.15, one of the highest in the world. Fogging keeps humidity between 45-55% to prevent static electricity from forming due to low humidity or condensation and rust formation due to high humidity.