NCAR Uses MeeFog System to Prevent Electrostatic Damage to its New Supercomputer

Data Centers

“Wyoming is very dry, so you need to avoid any static discharge situations,” says Autry. “The MeeFog system is there to avoid reaching too-low humidity in the data center.”

Krista Laursen, NWSC Project Director

Opening in 2012, the NCAR Wyoming Supercomputing Center (NWSC) is a 170,000 square foot data center with two 12,000 square foot raised floor spaces. The site will house the IBM Yellowstone 1.6 Petaflop supercomputer in one of those modules, with the other set aside for future expansion. “We have pursued ‘right-sized’ construction in order to limit capital construction costs while ensuring that we have the needed infrastructure to meet scientific community computing needs now and for the next 20-30 years,” says NWSC Project Director Krista Laursen. “We have built infrastructure that will support computing and data archival needs for at least the next decade, and should facility expansion be necessary down the road it can be accomplished in a straightforward fashion.” In addition to the computing space, the NWSC has 6,000 square feet of data storage and archival space, a 2,500 square foot network operations center, administrative offices and a visitor center, with 100,000 square feet devoted to mechanical and electrical equipment.

NCAR chose the Wyoming site, in part, because the climate would allow it to maximize the use of outside air and minimize the use of chillers. “The high and dry climate in Wyoming is ideally suited for the ‘free cooling’ design used in the NWSC,” says Laursen. “Such a design option might not make sense in other geographic regions.” Average summer afternoon temperatures in Cheyenne only reach the lower 80s, dropping into the 50s at night. From October to April, nighttime lows drop below freezing. With such a temperature range, all the air handlers are designed to use 100% outside air economization when appropriate. Because NCAR doesn’t want to take the chance of temperature excursions on its high-end equipment, the data center also includes two evaporative towers sending chilled water to heat exchangers at the fan wall. To ensure that the inlet temperature stays at the desired 75°F, the NWSC also has one 1000 ton chiller and two 100 ton chillers to further cool the water as needed, but it is not anticipated that these will be needed more than a few hundred hours per year.

Using outside air in a dry climate, however risks electrostatic discharge damage to the equipment. In Cheyenne, the relative humidity drops below 40% on summer afternoons, outside the ASHRAE recommended operating range. The bigger issue is on the winter days. Although the relative humidity tends to stay above 50% at the outside temperatures, it plummets when heating the air up in the data center: That missing moisture needs to be added to the incoming air to prevent electrostatic damage to the equipment.

Challenge:

When the National Center Atmospheric Research built its new supercomputing data center, it wanted to take advantage of the free cooling available from the high, dry Wyoming environment. This made humidification a necessity in the building, because introducing the dry air would put the $35 million supercomputer at risk for electrostatic damage.

Solution:

For reliable, energy-efficient humidification, NCAR installed a MeeFog system delivering fog into the air handlers, allowing them to safely use outside air.

The Installation:

Mark Labac, president of Edge Mechanical Systems, was the Mee representative responsible for the NCAR humidification system. The MeeFog system consisted of two FM-200-B271P ceramic plunger pumps producing 2 gpm at 1000 psi. The pumps send the water through stainless steel tubing to arrays of impaction pin nozzles in two of the Air Handling Units and in the air supply for one of the data rooms. “The MeeFog system has some very thorough water treatment systems upstream so that the water is very clean by the time we are discharging it,” says Terry Autry, PE, a mechanical engineer and senior vice president for RMH Group, the engineering and design firm that oversaw the construction and commissioning of the NWSC’s mechanical and electrical systems. “The network of distribution nozzles discharge that fog into the return air path up high, then as that air continues down into the fan walls on the lower level, that fog is absorbed into the air stream.” The MeeFog system is tied into the Johnson Metasys control system that runs the AHUs, ensuring that the both the temperature and humidity stay in the appropriate ranges no matter what the outside temperature and humidity. “Every AHU is set up for full outside air economization,” says Autry. “The offices, the UPS and battery rooms, the computing spaces, everything has that capability.”

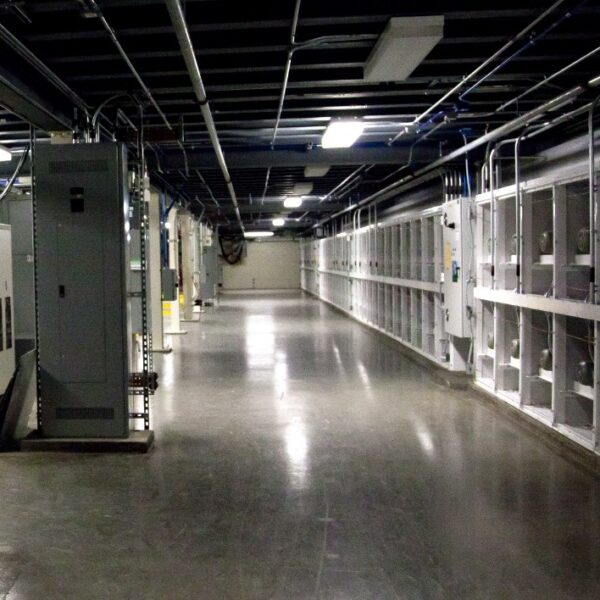

Installation Gallery

Cost-Benefit Analysis:

MeeFog systems have far lower energy costs than other types of humidification systems. For example, assuming a $.065 cost per kWh for electricity, 3500 hours of operation per year and 1000 lbs. of moisture output per hour, a MeeFog system costs $700 per year, compared with $14,350 for compressed air atomizers and $128,800 for electric steam humidifiers. In addition the MeeFog systems cool the air as they humidify it. “We do get some beneficial cooling from the MeeFog humidification so the other cooling systems have to work that much less,” says Autry. But, he doesn’t include the energy savings from the cooling in any efficiency calculations. Instead, he says the real value just comes from preventing damage to the equipment. With tens of millions of dollars of equipment at stake, that value overshadows any other. “Wyoming is very dry, so you need to avoid any static discharge situations,” says Autry. “The MeeFog system is there to avoid reaching too-low humidity in the data center.”

Benefits Of Meefog Technology:

Allows data centers to safely use outside air for cooling without damaging equipment.

Lower operating costs compared to other types of humidification systems.

Cools as well as humidifies the air

Energy Efficiency:

The MeeFog system uses only 1hp for every 600 lbs/hr of water. That’s far less energy than used by other humidifiers.MeeFog systems can provide very precise humidification control, +/- 1% or better.

“The network of distribution nozzles discharge fog into the return air path up high, then as that air continues down into the fan walls on the lower level, that fog is absorbed into the air stream.”