Humidification Systems for Ripening Rooms & Cold Food Storage

BlogWhat is Cold Storage Humidification & How Does it Work?

Cold storage and ripening chambers are systems that are used to control the ripening process of produce. Cold storage refers to holding produce in cold, temperature controlled rooms after being harvested and before being delivered to grocery stores. Cold storage ripening chambers are where produce is held after harvesting and then ripened to the specific requirements of the produce so that it is ready to eat and healthy looking by the time it gets to a supermarket.

Ripening chambers work by stimulating or controlling the natural ripening process by controlling the temperature, humidity, and supply of fresh air in the chamber as well as the levels of ethylene, CO2, and nitrogen that get released from the produce during the ripening process. By manipulating these conditions, ripening chambers are able to speed up or slow down the ripening process.

How Does a Ripening Room Function in Practice?

By controlling the ripening process, farmers are able to maximize their yield and maximize the amount of produce they can sell to supermarkets. For example, bananas have a ripening period of about 4 to 8 days after being harvested, but they require being transported by ship to get to the U.S. So, it is in the best interest of both the farmers and supermarkets to make sure the bananas ripen while being transported so that consumers can enjoy ripe bananas. By utilizing a ripening chamber, farmers can harvest bananas at an earlier stage (young bananas that are not ready to be eaten) and then control the ripening process during transportation in order to speed up the ripening process or, conversely, bananas can be picked closer to maturity and then have the ripening process slowed down in a ripening chamber.

The Importance of Humidification in Cold Storage & Ripening Rooms

One important factor in a proper ripening chamber is being able to maintain the necessary environmental conditions for the ripening process. One of the biggest issues people have with this process is maintaining proper humidity control. The chilly temperatures of a cold storage room reduce the moisture content of the air which causes the air to suck the moisture out of anything it can find, including the produce itself. This can cause product weight loss which also affects the appearance of the product and therefore the overall value of the product.

The only way to combat this issue is to use a humidification system; however, using any old humidification system can actually cause further issues if the control system is not precise enough or if the space is not being evenly humidified. Using a humidification system such as MeeFog’s cold storage humidification system will prevent humidification issues in ripening chambers because the MeeFog system is designed for precise control even in tight spaces with less airflow.

MeeFog’s Cold Storage & Ripening Room Humidification System

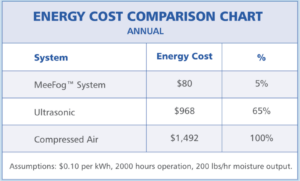

The MeeFog humidification system does more than just properly humidify and cool down rooms, it also contributes to significantly reduced energy costs and consumption compared to other humidification systems. The MeeFog fogging system uses specialized technology for optimum control and a fog nozzle set up that allows for uniform humidification that won’t build up on surfaces.

MeeFog saves up to 95% in energy compared to other systems.

MeeFog systems for ripening room humidification benefit the grower, the seller, and the consumer. MeeFog prevents the deterioration of produce in transportation and reduces energy costs. MeeFog systems are low maintenance, easy to service, and don’t contribute to the negative effects that permanent high humidity has on sensors and other valuable equipment used in ripening chambers.

In order to anticipate and control conditions in ripening chambers, MeeFog systems use ultra-fine water droplets that get dispersed evenly and do not build up on surfaces. Further, the humidity level is closely monitored by a humidistat that manages the system using real-time humidity and temperature readings. In fact, MeeFog systems are so efficient that Mee Industries has installations in more than 10,000 facilities around the world.

Benefits of MeeFog Systems for Cold Storage & Ripening Rooms:

- Improved keeping quality.

- Maintain product weight and value.

- Enhanced visual features.

- Optimum temperature control.

- Energy efficient, low cost operation.

- Easy to service and maintain.

- Ultra-fine fog droplets.

Specifications for MeeFog’s Easy to Maintain System:

- Direct drive pumps with high-efficiency motors.

- VFD with panel-mounted controller maintains pressure when zone valves open and close.

- Pressure transducer includes digital display.

- Anodized aluminum frame ensures long, corrosion free service.

- Low inlet-pressure and high discharge-pressure protection.

- UL certified, 508A enclosed industrial control panels.

Contact Us

If you are interested in a MeeFog humidification system please contact us to request a quote or for more information if you would like to know more.

Mee Industries specializes in providing custom-engineered, turn-key high-pressure fog solutions. We are committed to developing and supporting the most reliable fog systems available anywhere in the world. The MeeFog team looks forward to discussing your project with you.